ZENITH has rich experience in building stationary crushing plants for our clients. All capacities from 50-2000t/h are available here. Meanwhile, we can customize the crushing plants according to our clients' special requirements.

ZENITH has rich experience in building stationary crushing plants for our clients. All capacities from 50-2000t/h are available here. Meanwhile, we can customize the crushing plants according to our clients' special requirements.

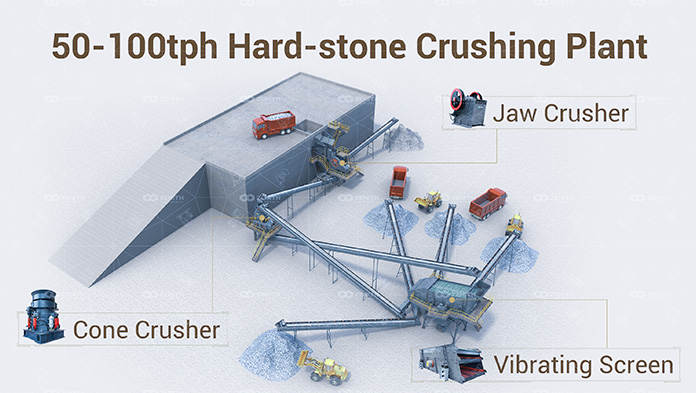

50-100t/h hard stone crushing plant is mainly composed of jaw crusher , cone crusher , vibrating screen and vibrating feeder.

It's usually used for crushing granite, basalt, river stone and andesite and so on.

The output sizes of the aggregates are adjustable. We can easily set the size according to different customers' different requirements.

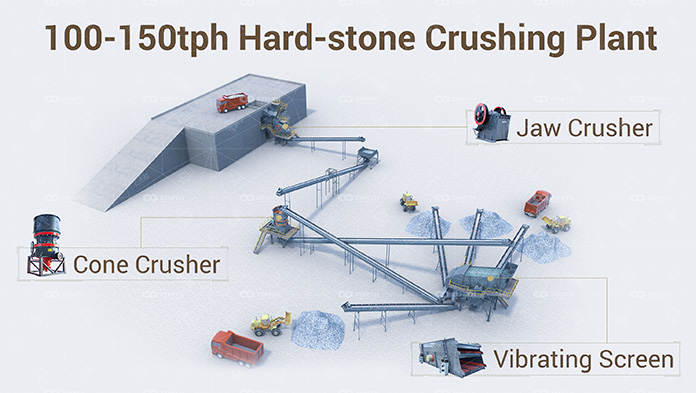

100-150t/h hard stone crushing plant is made of jaw crusher, cone crusher and feeder & screen. As the very popular scale, this crushing plant design is widely used in lots of quarries and it’s many advantages in processing basalt, river-stone and granite and many other high-hardness stones, such as low production cost, low labor cost and good aggregates shape.

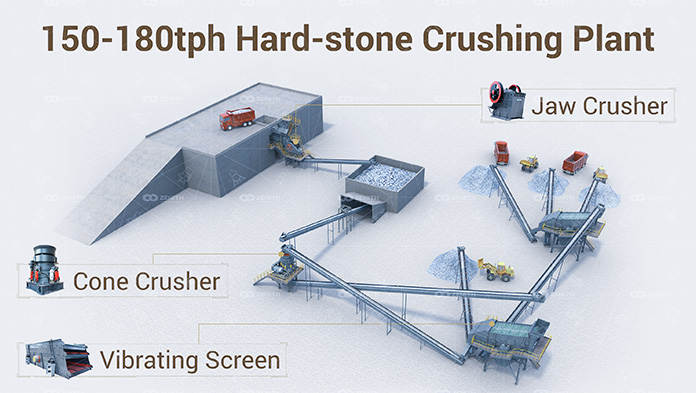

150-180t/h hard rock crushing plant fits for crushing the stone, whose hardness is above 4-5, such as basalt, river-stone and granite, etc. And this plant design mainly contains one jaw crusher, one cone crusher, one vibrating feeder and one vibrating screen, as a result, the whole investment cost is quite low and it's favored by lots of clients.

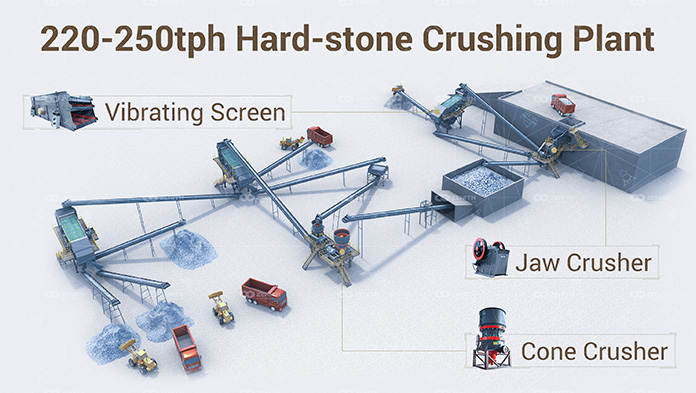

220-250t/h hard rock crushing plant is made of one vibrating feeder, one jaw crusher, two cone crushers and three vibrating screens. And the two cone crushers are a little different, one is HST cone crusher used to finish medium-crushing and another one is HPT cone crusher used to finish fine-crushing. Due to this design, the capacity is quite stable and the aggregates shape is good.

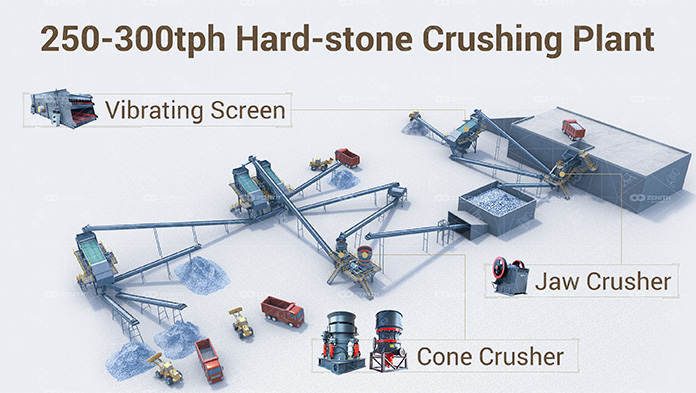

This is one very popular design of 250-300t/h hard rock crushing plant, it contains one HST cone crusher used to finish medium-crushing and one HPT cone crusher used to finish fine-crushing. Meanwhile, one jaw crusher and one vibrating feeder, four vibrating screens are also necessary. Also, this crushing plant can be used to process most of hard rocks for quarry and metal ore for refining.

380-450t/h hard rock crushing plant consists of one feeder, one jaw crusher used for primary crushing, one HST cone crusher used for secondary crushing, two HPT cone crusher for third-stage crushing and four vibrating screens. With this design, the capacity is quite stable and the aggregate shape is very good, thus, the price of the aggregates could be higher.

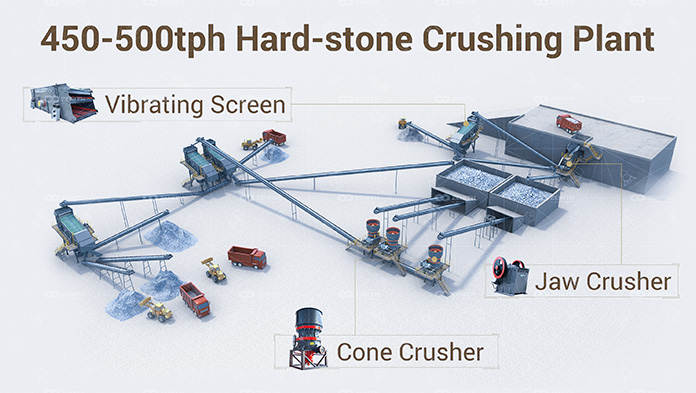

450-500t/h hard rock crushing plant consists of vibrating feeder, jaw crusher, cone crusher and vibrating screen, etc. And this design fully takes the scale into consideration, it could avoid unbalanced feeding and keep stable capacity. What’s more important is that the shape of aggregates is quite good and aggregates price will be higher.

.jpg)

650-700t/h hard rock crushing plant consists of vibrating feeder, jaw crusher, cone crusher and vibrating screen, etc. Because the scale is large, unbalanced feeding caused by transportation or mine blasting may easily happen. Thus, this crushing plant adopts many special design, which is able to keep stable capacity and good aggregates shape.

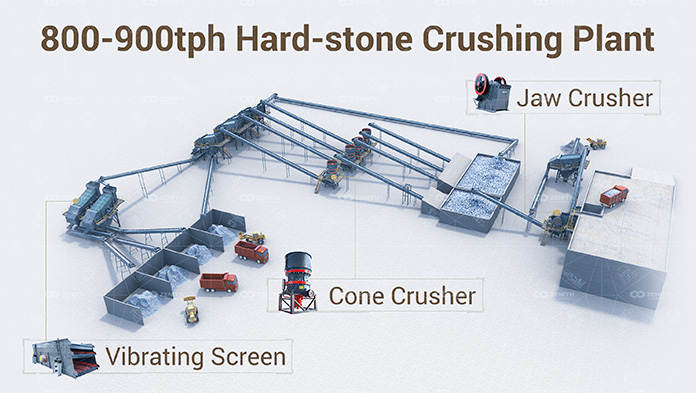

800-900t/h hard rock crushing plant mainly consists of one jaw crusher for primary crushing, one big HST cone crusher for secondary crushing, three small cone crushers for third-stage crushing and six vibrating screens for classification. It’s suit for not only producing aggregates but also metal ore crushing. What’s more important is that ZENITH has rich experience in building this plant, reducing the investment risk obviously.

.jpg)

1000-1050t/h hard rock crushing plant contains one big jaw crusher, two large HST cone crusher for secondary crushing, three cone crusher for third-stage crushing and many vibrating screens and feeders. Also, one transfer-hopper is necessary. Benefit from ZENITH’s rich experience, lots of enterprises prefer ZENITH as the cooperator, which help them reduce the risk.

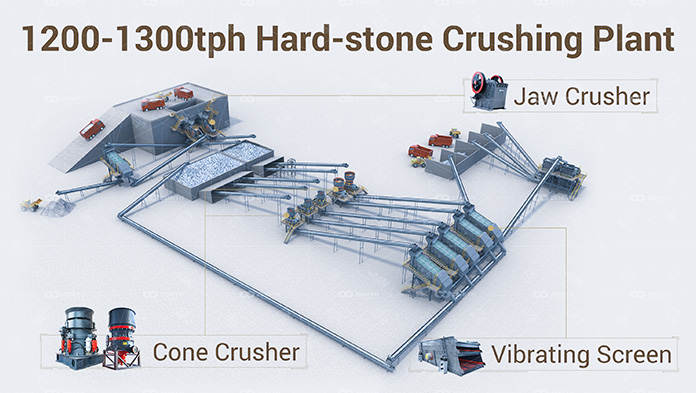

1200-1300t/h hard rock crushing plant is quite large scale crushing plants for quarries. So the primary crusher often contains two sets jaw crusher. The medium and fine crushers contain five cone crushers. And many vibrating screens and vibrating feeders are also needed. Because the total investment is a little high, lots of enterprises prefer ZENITH, whose rich experience could reduce the risk.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.