South Africa is one of the countries with the richest mineral resources in the world. It is famous for its large scale of resources and good storage conditions.

Since the large-scale development of diamond and gold mines in South Africa in the second half of the 19th century, mining has always been the backbone of South Africa's economy. In the 21st century, with the development of South Africa's secondary and tertiary industries, the proportion of mining in South Africa's national economy has declined, but it is undoubtedly still the cornerstone of the South African economy.

South Africa is one of the countries with the richest mineral resources in the world. It is famous for its large scale of resources and good storage conditions. There are more than 70 kinds of minerals with proven reserves. Except for oil reserves, which are relatively small, it has almost all the important mineral resources, and its reserves are also in the leading position in the world.

The production of gold and diamonds ranks first in the world. Technologies such as deep well mining are world leaders. Mining, manufacturing, agriculture and service industries are relatively developed and are the four pillars of the economy.

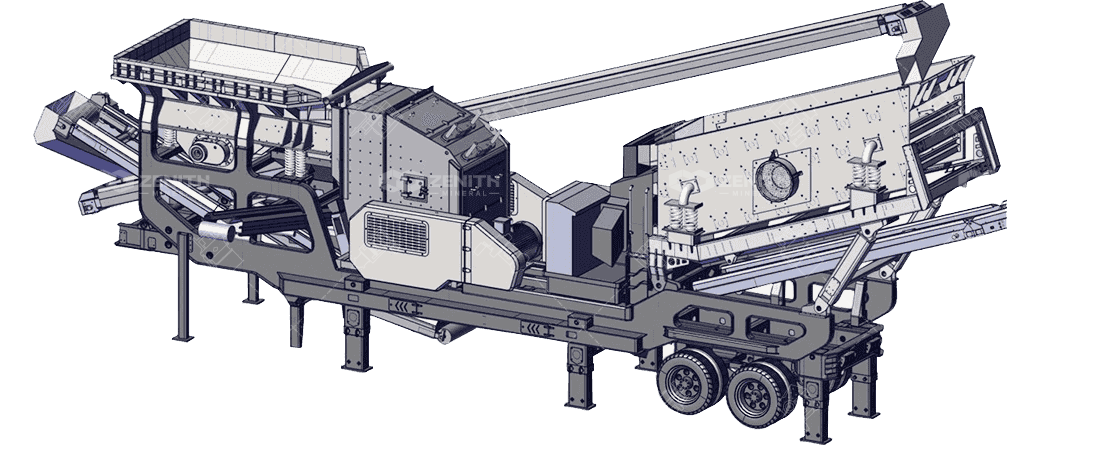

The mobile crushing station is composed of crusher, screening system, debris sorting device, conveying mechanism, vibrating feeder and self-propelled function. And, by placing the action mechanism in it, it can be said that the production line is mobile.

If you put raw materials directly into the crusher, it will have a huge impact on the crusher. For a long time, it will cause uneven stress and affect the normal operation of the equipment. Therefore, it is necessary to install a vibrating feeder before the crusher. The biggest advantage of the vibrating feeder is that it can evenly feed the material.

In the mobile crusher plant, crusher is the core component, and crushing and processing raw ore is its main task. While choosing crusher, the properties of raw ore should be considered, such as the hardness, moisture content, size and so son.

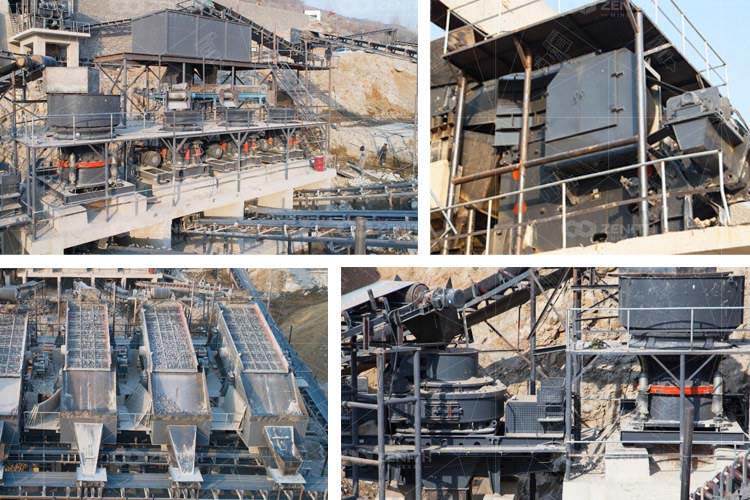

In order to produce high-quality aggregates, if it is difficult to complete the primary crushing as required, secondary crushing is required, which requires an additional screening system to screen the larger-sized raw materials, and then send them to the crusher for re-crushing.

The tire-type and crawler-type traveling mechanisms are two important traveling mechanisms in the mobile crusher station. The tire-type walking mechanism is convenient for walking on ordinary roads, the turning radius is small, it can be quickly stationed in the production site, the equipment is highly flexible, and time is saved. The crawler-type walking mechanism can walk smoothly, has a lower grounding specific pressure, and can effectively adapt to the wetland and mountain environment. It is usually applied to the full hydraulic drive system, which has high reliability and large driving force.

According to the walking mode, mobile crusher station can be divided into a tire-type mobile crusher station and a crawler-type mobile crusher station. They have the following similarities:

1. Flexible and time-saving

The mobile crusher can directly reach the mining site, and is not affected by site changes. It can start operation after completing the adjustment of the station in a short time. Due to the small size of the equipment, it is especially suitable for the place where the crushing site is narrow. At the same time, it eliminates the cumbersome steel frame structure and foundation construction when broken, saving a lot of time.

2. Integrated complete unit

The integrated unit equipment installation form eliminates the complicated site infrastructure installation work of the split components, reduces the consumption of materials and man-hours, and is a production line that integrates process equipment such as material receiving, crushing, and conveying. The reasonable and compact space layout of the unit improves the flexibility of site stationing.

3. Reduce material transportation costs

The mobile crusher station in South Africa can process materials on site without having to move the materials off site for reprocessing, which greatly reduces the transportation cost of materials.

4. Flexible combination and complete functions

In mobile crusher plant, the plant can be equipped with corresponding equipment according to the actual production requirements of customers, various combinations can be made to form a "crushing before screening" process, or a " crushing after screening" process, which can be combined into a two-stage crushing and screening system for coarse crushing and fine crushing. It can also be combined into a three-stage crushing and screening system of coarse crushing, medium crushing and fine crushing, and can also operate independently with great flexibility.

As professional manufacturer, ZENITH provides K series mobile crusher for sale in South Africa. It has different models for customers to choose, is suitable for processing granite, marble, basalt, limestone, quartzite, pebble, iron ore, copper ore, mine waste, construction waste, etc.

K Series mobile crusher

K series Portable Crushing Plant uses modular vehicle design, able to be transported without disassembly. Besides, it boasts rapid installation and production, safety and environmental protection.

Input Size: 0-930mm

Capacity: 0-650t/h

Features: modular vehicle design, more flexible, rapid installation and production, safety and environmental protection

The mobile crusher is very popular in South Africa, Which has helped our customers create great value, so what's the magic of this equipment?

1. The mobile crusher station is a complete set of equipment that has been manufactured by the manufacturer. It does not need to be installed on site, and it can be used when it is powered on;

2. The main machine of the mobile crusher station can be switched freely, which can meet the different needs of different customers, and realize the multi-purpose of one machine, and the operation are more flexible and convenient;

3. The length of the mobile crusher station is short, and different crushing equipment is installed on the independent movable chassis, with short wheelbase and small turning radius, which can be driven flexibly in the ordinary highway and operating area;

4. The mobile crusher station can directly crush the raw material on site, without having to move the raw material away from the site for reprocessing, which greatly reduces the transportation cost of materials;

5. Mobile crusher for sale in South Africa adopts two modes of oil and electricity, which is convenient for field operations, flexible in movement, can walk on its own, and adopts remote control or manual driving;

6. In mobile crusher plant, the plant can be equipped with corresponding equipment according to the actual production requirements of customers, various combinations can be made to form a "crushing before screening" process, or a " crushing after screening" process, which can be combined into a two-stage crushing and screening system for coarse crushing and fine crushing. It can also be combined into a three-stage crushing and screening system of coarse crushing, medium crushing and fine crushing, and can also operate independently with great flexibility.

7. The mature design scheme creates a green and pollution-free crushing environment;

8. Mobile crusher for sale in South Africa adopts new centralized lubrication system and unified maintenance toolbox design, maintenance is more convenient, and a lot of labor and time costs can be saved;

9. Low investment pressure;

10. A single machine can save more than 60% of energy.

If you want to know more about ZENITH mobile crusher for sale in South Africa, feel free to contact us!

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

In Nigeria, Stone crushing is an important part in mining industry and require high quality stone crushing machines.

Stone crusher can be widely found in South Africa mining site, it is the basic machine for mineral processing line. Zenith will provide you with crushers of different styles and sizes at the best price according to your requirements.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.