With the rapid development of national infrastructure and industrial construction, the types and models of stone crusher machine are also increasing, which provides more choices for customers.

At the same time, customers will face the situation that they do not know how to choose the appropriate stone crusher machine and they also want to know about the stone crusher machine price when selecting crushing equipment.

According to the working principle, stone crusher machine can be generally divided into extrusion type and impact type.

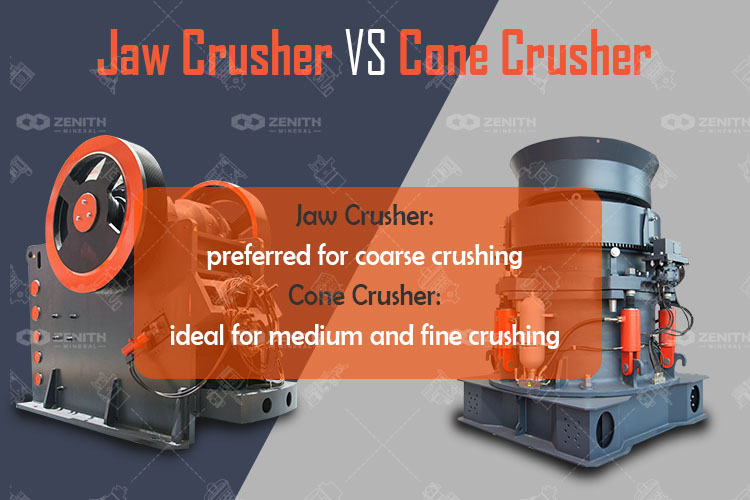

The stone powder content in the products produced by extrusion type stone crusher machine is low, and the proportion of needle-like particles is large. The common types of extrusion type stone crusher machine mainly include jaw crusher, gyratory crusher, cone crusher, etc.. The impact type stone crusher has a relatively simple structure, large crushing ratio and good product grain shape. Common types mainly include impact crusher, hammer crusher and sand making machine.

Generally, in sand and gravel production plant, the coarse crushing process generally adopts jaw crusher, gyratory crusher or hammer crusher; the medium crushing process generally adopts cone crusher or impact crusher; fine crushing and making machine process generally adopt sand making machine or cone crusher.

Jaw crusher has the advantages of simple structure, high reliability of continuous operation and low price. Its discharge opening is adjustable, and the height difference of plant required for equipment layout is small. Its disadvantage is that the lining plate is easy to wear, and the product particle size distribution is uneven.

Jaw crusher is not easy to block when crushing ores with large moisture content and high clay content, suitable for processing sand aggregate raw materials and it is often used in the coarse crushing stage.

The remarkable feature of the gyratory crusher is its large production capacity. When the sizes of feed opening and discharge opening of gyratory crusher and jaw crusher are the same, the output capacity of gyratory crusher is 2.5~3 times that of the jaw crusher.

Due to the high overall investment and large amount of civil works, the gyratory stone crusher machine is more suitable for large scaled projects.

The cone crusher has large crushing force, large crushing ratio and large processing capacity. It has good adaptability to most materials, materials with high hardness and difficult to crush. As medium and fine stone crusher machine, it has high output and reliable operation. However, the manufacturing and maintenance of the hydraulic system and the moving cone support structure of the cone crusher are more complex, and it has relative higher price, so the investment cost is high.

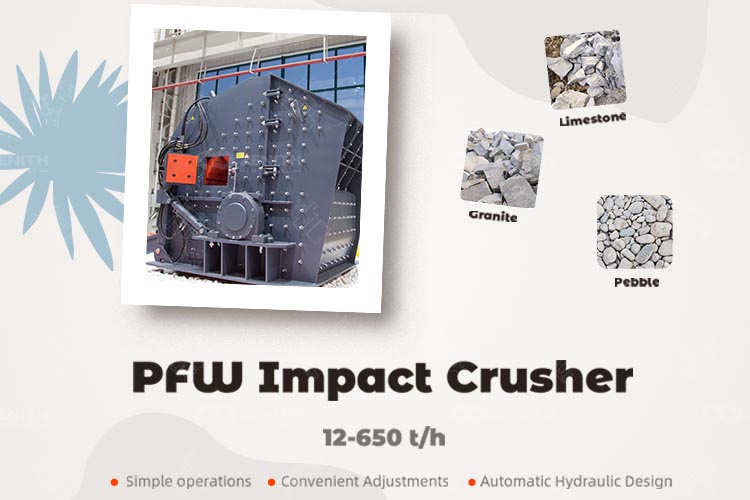

Impact crusher and hammer crusher has similar structure, they have large crushing ratio and low energy consumption. And the shortcoming is that the plate hammer and impact plate are easy to wear, making these two stone crusher machine suitable for processing friable materials.

The sand making machine has the advantages of small volume, simple foundation, high crushing efficiency, large output, low maintenance, etc. This type of stone crusher machine has various crushing cavities under different working conditions, suitable for the fine crushing and ultra-fine crushing of most materials. And sand making machine can be used for shaping and sand making.

ZENITH sand making machine has ‘rock on rock’ crushing cavity and ‘rock on iron’ crushing cavity for customers to choose. Generally, sand making machine with ‘rock on rock’ crushing cavity is used for shaping and ‘rock on iron’ crushing cavity is used for sand making.

For these different types of stone crushing machine, ZENITH produces various different models for different production requirements, making sure the recommended crusher is suitable for you.

With the development of different stone crusher machines, many customers want to know about the price. The stone crusher machine price is related with many factors, such as the model, the configuration and so on.

The price range of crushers commonly used in the market is as follows:

1. Jaw Crusher:

2. Gyratory Crusher:

3. Cone Crusher:

4. Impact Crusher:

5. Sand Making Machine:

It's important to note that these price ranges are approximate and can vary significantly based on factors like brand, customization, location, and any special requirements. The factors that usually affect the price of crushers are as follows:

1. Type and Model

The type and model of the stone crusher are the primary factors affecting its price. Different types of crushers, such as jaw crushers, gyratory crushers, cone crushers, impact crushers, and sand making machines, have different price ranges due to their distinct designs and capabilities. For instance, a jaw crusher will generally be less expensive than a gyratory crusher due to differences in size and capacity.

2. Configuration and Automation

The level of automation and the specific configuration of the crusher can also impact the price. Higher levels of automation and advanced control systems can increase the cost but may offer long-term benefits in terms of efficiency and reduced operational costs.

3. Technology and Efficiency

Advanced technologies incorporated into the crusher, such as energy-saving mechanisms and improved wear-resistant materials, can increase the initial cost but can lead to lower maintenance costs and higher efficiency over time.

4. Market Demand and Supply

The price of stone crusher machines is also influenced by market demand and supply. During periods of high demand, prices may increase, while an oversupply can lead to lower prices.

5. Manufacturer and Brand

Different manufacturers and brands may charge different prices for similar models due to differences in brand reputation, quality, and after-sales service.

6. Location and Transport

The location of the manufacturer and the transport costs to the project site can also affect the final price. Importing crushers from abroad may involve additional costs such as tariffs and shipping fees.

The price of stone crusher machines is a complex subject that depends on various factors. By understanding these factors and following the steps to get an accurate price quote, you can make an informed decision when investing in crushing equipment.

Sand and stone aggregate as the basic material of engineering construction, its commonly used raw materials are pebbles, granite, diabase, basalt, limestone and so on. For different raw materials, the choice of stone crusher machine is also different.

When selecting stone crusher machine, we should not only consider one reason, but also consider many aspects. Crushing equipment is mainly affected by the type and hardness of materials, water content, and cleavage degree and particle size of incoming and outgoing materials. In addition, the construction site and output should also be considered.

The type and hardness of materials is an important principle for selecting a stone crusher machine. The hardness of different materials is different, and the hardness of materials is usually expressed by Mohs hardness. There are 10 levels of Mohs hardness. The greater the Mohs hardness number, the harder the ore will be, and the harder it will be to break, and vice versa.

For materials with high hardness, we should consider jaw crusher, gyratory crusher and cone crusher, and then impact crusher (shaping machine) is used for shaping according to the requirements of finished products.

For materials with low hardness, we can consider jaw crusher, impact crusher and hammer crusher, and then impact crusher (shaping machine) is used for shaping according to the requirements of finished products.

Tip: the hardness of limestone varies greatly according to its silicon content. If it is limestone with high silicon content, cone crusher shall be used for medium and fine crushing.

The moisture content of the material will also affect the selection of the stone crusher machine. When the water content is too large, the fine materials will be agglomerated or stuck to the coarse materials due to the increase of humidity, thus increasing the viscosity of the materials, reducing the ore discharging speed and reducing the productivity. In serious cases, it may even cause blockage of the ore discharge mouth, affecting the normal production.

The degree of cleavage development of raw ore also directly affects the productivity of the stone crusher machine. In the crushing process, the materials are crushed along the cleavage plane, so the productivity of the crusher is correspondingly much higher than that of the ore with dense crushing structure when crushing the ore with developed cleavage.

The particle size of feed and discharge materials is used to judge the model and crushing level of the required stone crusher machine.

If the content of coarse particles in crushed materials is high or the ratio of the largest ore feeding block to the ore feeding width is large, the crusher needs to achieve a large crushing ratio, the productivity will reduce; If the content of fine particles in crushed materials is high or the ratio of the largest ore feeding block to the ore feeding width is small, the crusher needs to achieve a large crushing ratio, the productivity will correspondingly improve.

The area of the construction site is also one of the factors that we should consider while choose a stone crusher machine. In addition, the location of crushing equipment also affects the selection of crusher.

The output capacity is also an important indicator to determine the selection of stone crusher machine. Generally, the higher the output capacity requirements, the larger the size of crushing equipment required, and the corresponding input and output will increase.

At ZENITH, we offer a wide range of stone crusher machines to suit different production requirements. Contact us for personalized advice and competitive pricing on our crushers. Our engineers will be happy to introduce the machines in detail and help you find the best solution for your project.

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

The mobile crusher is very popular in South Africa, Which has helped our customers create great value, so what's the magic of this equipment?

Stone crusher can be widely found in South Africa mining site, it is the basic machine for mineral processing line. Zenith will provide you with crushers of different styles and sizes at the best price according to your requirements.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.