Construction and demolition (C&D) waste is not real garbage, but misplaced "gold". Construction and demolition (C&D) waste can be processed into renewable resources and recycled into production after passing through multiple processes such as iron removal, air separation, crushing and screening with professional equipment.

Construction waste mainly includes mortar, concrete, masonry, reinforced concrete pile heads, scrap metal, wood, packaging materials and other wastes generated in various stages of project construction.

During the construction process, a large amount of solid waste is generated, mainly including mortar, concrete, bricks, and reinforced concrete pile heads, scrap metal, wood, packaging materials, etc., accounting for approximately 80% of the total waste. This is a considerable amount of recyclable resources, and if effectively treated, it can greatly reduce resource waste and generate economic benefits.

Decoration waste includes resources such as wood, packaging, steel, glass, and plastic, accounting for approximately 30% of the total waste content. If effectively utilized, this is also a considerable amount of recyclable resources.

A large number of solid wastes are produced in the process of building demolition, including 80% of recyclable resources, which is of great value, but also difficult to recover.

(1) Waste building concrete and waste bricks& stones can be used to produce coarse and fine aggregates, which can be used to produce corresponding strength grades of concrete, mortar, or to prepare building materials such as blocks, wall panels, and floor tiles. After adding solidified materials to coarse and fine aggregates, they can also be used for road pavement base layers.

(2) Use waste bricks and tiles to produce aggregates, which can be used to produce building materials such as recycled bricks, blocks, wall panels, and floor tiles.

(3) Residue can be used for road construction, pile foundation filling, foundation, etc.

(4) For the waste wood construction waste, the wood that has not been obviously damaged can be directly used for reconstruction, while the seriously damaged wood components can be used as raw materials for wood regeneration boards or paper making.

(5) The asphalt mixture of waste pavement can be directly used for recycled asphalt concrete in an appropriate proportion.

(6) Waste road concrete can be processed into recycled aggregates for preparing recycled concrete.

(7) Scrap steel, steel reinforcement, and other scrap metal materials can be directly reused or recycled for processing.

(8) Construction waste such as waste glass, waste plastics and waste ceramics can be used differently depending on the situation

The resource utilization of construction and demolition (C&D) waste is first to pretreat the construction waste to meet the requirements of recycling. A large amount of construction waste is pretreated mainly by mechanical sorting, supplemented by manual sorting. The pretreated construction waste can be directly recycled, or can be further processed and utilized as required.

The further process of construction waste is mainly finished by professional equipment, such as crushing and screening equipment.

At present, the widely used construction treatment process is as follows: raw material loading → primary crushing → manual sorting of impurities → automatic sorting of impurities → secondary crushing → screening and removal of impurities → finished aggregate.

After the recycling treatment of construction waste is completed, the amount of waste is reduced, and the harm of construction waste is eliminated to achieve harmless treatment.

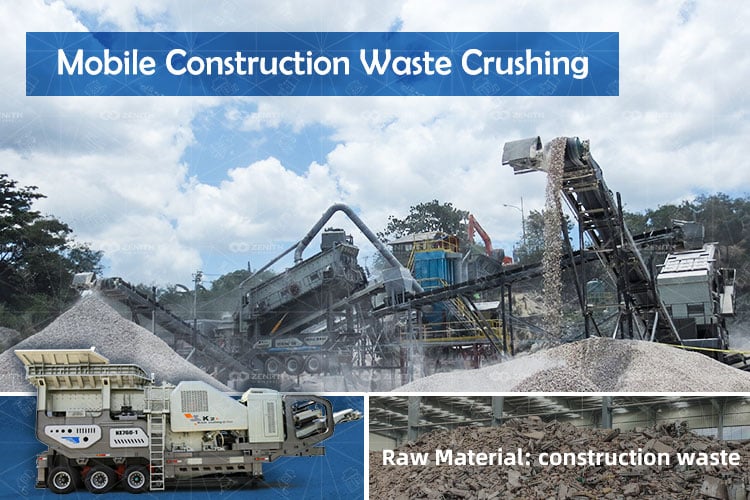

On site crushing and sorting of construction waste

It refers to the use of demolished old construction waste and newly built construction waste generated in the process of urban and rural construction to realize on-site screening and crushing through relevant technology, so as to provide raw materials for on-site construction. On the one hand, it reduces the space for stacking garbage and the funds for garbage removal; on the other hand, it reduces the purchase of new materials, and further reduces the project cost.

Impurity removal

The construction waste is fed through an excavator, and the waste is removed and pre-screened by the heavy screening station to screen out 30% of the fine material in the construction waste. At the same time, a manual sorting platform is equipped to sort out lightweight materials such as wood blocks, plastics, and fabrics etc. Large diameter materials that need to be crushed enter a mobile crusher for crushing. The screened soil can be used as greening soil for the landscaping department.

Crushing process

The construction waste is transported to the crusher through a heavy-duty screening machine for crushing. The crushed materials are transported to the returned material screening unit through the main conveyor belt. Materials larger than the screen size are transported to the silo by the return belt conveyor and continue to be crushed by the crusher. Materials smaller than the screen size are transported to the mobile screening equipment by the under-screen belt conveyor.

Screening process

For construction waste screening, we can adopt a mobile screening station with three layers. The crushed materials are transported to the silo of the mobile screening equipment and then fed to the vibrating screen through vibrating feeder for screening process. The screened products can be divided into four types of recycled aggregates that can replace natural sand and gravel, namely 0-5mm, 5-10mm, and 10-31.5mm. If there are different needs, the product particle size can be controlled by changing the screen size. Large particle size aggregates can be mixed with water stable graded crushed stones for use, while small particle size aggregates can be used for deep processing, such as making pedestrian walkway bricks, lawn bricks, etc.

Crushing and screening equipment is the key to the recycling of construction and demolition waste. For construction waste treatment, ZENITH recommends mobile crusher. Here are the reasons why mobile crusher is the ideal choice:

The use of construction waste has undergone great changes in the past half century. From being simply used for garbage dumping and landfilling, to partially recycled for building backfill, park foundation construction, and road reclamation, to today's processing and reuse as building aggregates. The recycling rate of construction waste is getting higher and higher, and the added value of its reprocessed products is also getting higher and higher.

The appearance of construction waste mobile crusher has solved the problem of environmental pollution. As a senior manufacturer of construction waste treatment equipment, ZENITH has always taken green environmental protection and resource regeneration as the development goal, constantly improved the technical functions of mobile crusher, and comprehensively and systematically solved the environmental pollution caused by construction waste.

the aggregate formed by waste concrete through multiple screening, crushing, cleaning processes combination and classification, and mixed in a certain proportion is called recycled concrete aggregate, recycled aggregate for short.

Concrete crushers are machines that are designed to reduce the size of concrete structures and buildings. There are 7 types of concrete crushers that are used for different purposes.

Construction waste treatment and reuse is a way to solve the siege of urban construction waste with both economic and social benefits.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.