Portable crusher plant has become an essential component in the construction and mining industries, providing flexibility and efficiency in material processing. These plants are designed to be easily transported and set up at various job sites, allowing for quick adaptation to changing project requirements. However, the longevity and performance of portable crusher plant heavily depend on their lubrication systems. This article explores the critical role of lubrication systems in enhancing the lifespan and operational efficiency of portable crusher plant.

A lubrication system is designed to reduce friction between moving parts, minimize wear and tear, and prevent overheating. In portable crusher plant, the lubrication system typically consists of various components, including pumps, filters, reservoirs, and distribution lines. The primary function of this system is to ensure that all critical components, such as bearings, gears, and hydraulic systems, receive adequate lubrication.

1. Manual Lubrication Systems: These systems require operators to manually apply lubricant to various components at specified intervals. While they are simple and cost-effective, they can lead to inconsistent lubrication and increased wear if not properly maintained.

2. Automatic Lubrication Systems: These systems provide a continuous supply of lubricant to critical components without the need for manual intervention. They can be further categorized into:

One of the primary functions of lubrication is to reduce friction between moving parts. In portable crusher plants, components such as bearings, gears, and shafts experience significant stress and wear due to constant movement and heavy loads. Proper lubrication forms a protective film between these surfaces, minimizing direct contact and reducing wear. This not only extends the life of individual components but also enhances the overall durability of the entire plant.

Portable crushers operate under high loads and can generate substantial heat during operation. Without adequate lubrication, friction can lead to overheating, which can cause components to fail prematurely. Lubricants help dissipate heat by carrying it away from critical areas, maintaining optimal operating temperatures. This is particularly important in hydraulic systems, where overheating can lead to fluid breakdown and system failure.

Dust, dirt, and other contaminants are prevalent in construction and mining environments. These particles can enter the lubrication system and cause damage to internal components. A well-designed lubrication system includes filters that remove contaminants from the lubricant before it reaches critical components. This protection is essential for maintaining the integrity of the lubrication system and ensuring the longevity of the portable crusher plant.

Efficient lubrication contributes to the overall operational efficiency of portable crusher plants. When components are properly lubricated, they operate more smoothly, reducing energy consumption and improving productivity. Conversely, inadequate lubrication can lead to increased friction, resulting in higher energy costs and reduced output. By ensuring that all moving parts receive the necessary lubrication, operators can maximize the efficiency of their portable crusher plants.

Regular maintenance and unexpected breakdowns can significantly impact the productivity of portable crusher plants. A well-maintained lubrication system reduces the likelihood of component failure, minimizing downtime and maintenance costs. By investing in a reliable lubrication system, operators can ensure that their portable crushers remain operational for longer periods, ultimately leading to increased profitability.

To maximize the benefits of lubrication systems in portable crusher plants, operators should follow best practices for maintenance:

The lubrication system is a critical component of portable crusher plant, playing a vital role in reducing friction, preventing overheating, protecting against contaminants, enhancing operational efficiency, and minimizing downtime. By prioritizing the maintenance and optimization of lubrication systems, operators can significantly extend the lifespan of their portable crushers and improve overall productivity. Investing in quality lubricants and implementing best practices for lubrication system management will ultimately lead to more efficient and profitable operations in the demanding environments of construction and mining.

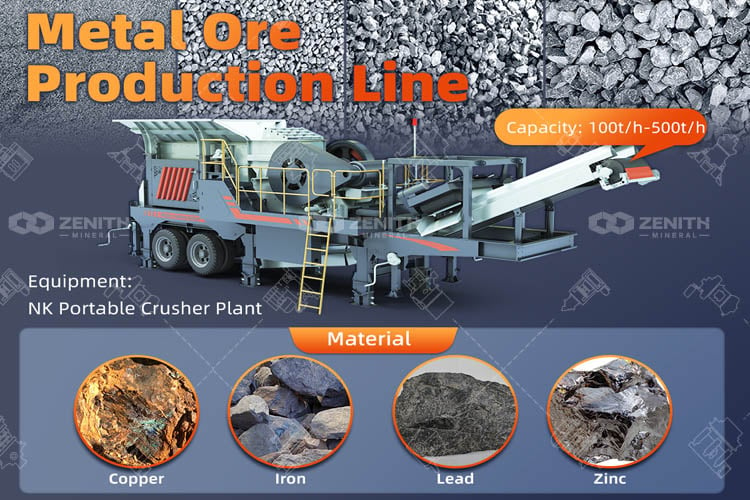

The NK Portable Crusher Plant is a powerful asset in the metal ore production line, offering a combination of high capacity, mobility, and advanced control systems.

This article explores the financial benefits of investing in a high-quality portable crusher plant, highlighting how it can positively Improves your ROI.

What Makes Portable Crusher Plant Essential for Modern Operations?As construction and mining projects adapt to changing needs, portable crusher plant have becom

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.