As construction and mining projects adapt to changing needs, portable crusher plant have become indispensable. Their portability allows crushing to occur on-site, eliminating waste from transportation of raw materials. This mobility, combined with other advantages, make portable crusher plant an essential part of efficient modern operations.

Portable crusher plant can be quickly transported from one project to another, avoiding delays compared to stationary crushers. This flexibility suits contractors handling small to medium volume work across variable terrains. Mobile units allow crushing and screening to occur near excavation sites or in hard-to-access areas like mountainsides.

The self-contained design eliminates the need for extensive civil works common to stationary plants. Rapid setup and teardown let operators follow work rapidly across sites. These benefits are invaluable when projects require frequent relocation or have tight deadlines.

In demanding applications, portable crusher plant deliver consistent, high-quality performance. Their fully-integrated hydraulic systems provide smooth start-ups and response under load. Automated controls help stabilize output flows.

Portable units cope admirably with moisture, dealing effectively with damp feed materials prone to clogging. Their balanced, track-mounted carriage distributes weight evenly for stability on soft ground. With dust-sealed electrical components, they deliver reliable uptime even in dusty quarries or hot, humid mines.

ZENITH is continuously integrating the latest technologies to optimize portable crushing plant performance. Real-time hydraulic adjustability allows operators to precisely match throughput to changing production demands.

Advanced condition monitoring systems employ vibration sensors and telemetry to remotely track plant health. This enables preventive maintenance, reducing downtime costs. Automatic lubrication schedules lower labour needs for routine servicing.

Telematics connectivity provides offshore access to critical operating data. Plant managers can identify optimization opportunities or troubleshoot issues remotely. This fast decision-making improves overall equipment effectiveness.

Direct-drive electric plant designs enhance fuel efficiency by up to 30% compared to diesel-hydraulic variants. Integrated emergency kill switches prioritize worker safety. Jointly, these technologies maximize safe output while lowering lifecycle expenditure.

To achieve these benefits, some essential components are required:

With a complete, top-quality mobile aggregate plant setup, operators gain a single, flexible solution for crushing and screening needs on diverse project sites.

Yes - multiple factors contribute to lower operating expenses compared to stationary plants:

In conclusion, portable crusher plant have become indispensable assets for modern operations across various industries. Their unmatched flexibility, reliability, and cost-effectiveness make them essential tools for achieving operational excellence in today's dynamic business environment. By embracing the capabilities of portable crusher plant and leveraging their full potential, businesses can drive productivity, profitability, and sustainability in the long run.

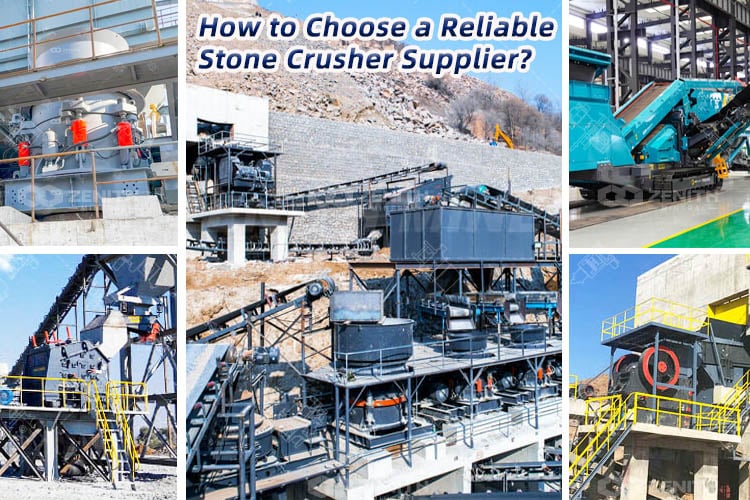

Choose a reliable stone crusher supplier with this professional guide. Learn key steps: assess needs, check reputation, product quality, after-sales support, and cost-efficiency for optimal operations

In this article, we will provide a detailed guide on how to set up a small-scale gold processing plant, from the initial stages of research and planning to the installation and operations of the plant.

A comprehensive guide on selecting the right gold gravity concentrator for your mining operation. Learn about different concentrator types, key selection criteria, and optimization strategies to maximize gold recovery rates.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.