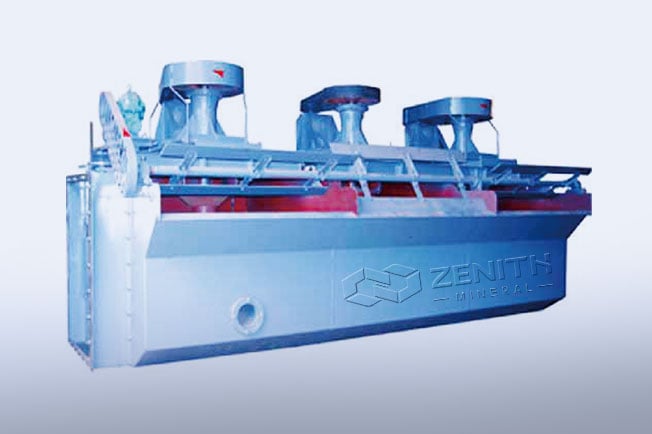

When the XJ-type flotation machine operates, the motor drives the impeller to rotate, generating centrifugal force and negative pressure. This process results in the absorption and mixing of air with the mineral slurry, as well as the blending of additives. The mineral slurry and foam combine, allowing the mineral to float to the surface and form mineralized foam. The liquid surface height can be adjusted using the adjustment flashboard to scrape off the useful foam with a squeegee.

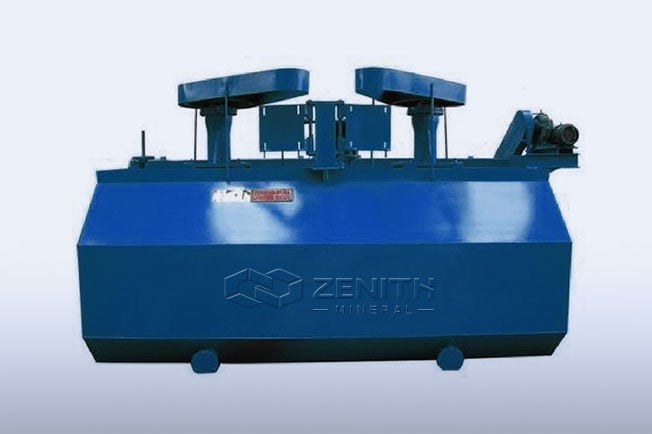

The BF-type flotation machine is an enhanced version of the SF flotation machine with the following features:Enclosed two-section impeller design promotes strong downward circulation in the pulp.

High suction intensity with low energy consumption.

Each slot combines suction, pulp absorption, and flotation functions, creating a self-contained flotation loop without additional equipment.

Horizontal slot configuration allows for easier modifications.

Efficient pulp circulation reduces coarse sand sedimentation.

Equipped with self-control and electric control devices for convenient regulation.

Structural features: Capable of self-absorbing air and pulp, the SF-type flotation machine features caster-style, two-sided blades on the impeller for double circulation within the slot. The machine has a large clearance with the cover plate, minimizing impact during abrasion. It offers significant suction intensity, a forward-leaning slot body, and minimal dead angles, facilitating fast foam movement.

High suction intensity and low energy consumption; no need for a foam pump due to its vertical layout; low impeller peripheral speed; durable cover plate; efficient downward and upward pulp circulation for optimal suspension of coarse minerals. When combined with a JJF-type flotation machine, it forms a united flotation machine, acting as the suction slot for each operation.

XCF and KYF are enforced aeration flotation cells widely used for processing non-ferrous metals, ferrous metals, and non-metallic minerals. They are often operated together and share similar structural features and overall dimensions.

Smaller impeller diameter and lower power consumption, saving 30%-50% of power.

Equipped with an air distributor in the tank for even air dispersion.

The impeller acts as a centrifugal pump, suspending solid particles.

U-shaped tank design minimizes sand settlement.

Even impeller wear due to reasonable design, leading to low reagent consumption and operation costs.

Simple structure with easy maintenance; convenient slurry level adjustment with auto electro-controlling devices.

KYF series has low power consumption as it cannot suck slurry spontaneously, while XCF series, which can, has higher power consumption.

Generally used as cell units, with XCF functioning as the suction flow tank and KYF as the direct flow tank. Horizontal allocation of cell units without a foam pump is possible.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.