The double bending wave shaking table is a novel hydromechanical ore dressing equipment. It boasts a large capacity, high ore dressing recovery ratio, high concentration ratio, and exceptional adaptability. This table is extensively used for roughing and cleaning operations on various ores like tungsten, tin, lead, zinc, gold, silver, manganese, and ilmenite, or in sand processing plants to handle particles ranging from 0.019mm to 3mm. Our company includes an ore dressing lab to assist customers in conducting ore dressing experiments and designing process flows.

The sawtooth wave jigger is a highly efficient and energy-saving gravity separation device, an advancement from the traditional sine wave jigger. It swiftly raises water and gradually lowers it, overcoming the time inefficiency of the sine wave jigger, which spends equal time in raising and lowering water. Compared to the sine wave jigger, the sawtooth wave jigger achieves higher operation recovery ratios of Sn: 3.01%, W: 5.5%, and reduces water consumption by 30-40%. It finds wide application in enriching low-grade manganese ores and limonite, recovering non-ferrous metals from industrial furnace slag, and extracting valuable minerals from river sands like gold, tungsten, tin, manganese, iron, lead, zinc, antimony, and diamonds, exhibiting excellent performance.

The spiral chute is a new type of gravity separation equipment suitable for separating metallic minerals within the granularity range of 4-0.02. It is effective for separating iron, ilmenite, chromite, pyrite, tungsten ore, tin ore, tantalum-niobium ore, gravel mines, zirconite, rutile, as well as other nonferrous metals, rare metals, and nonmetallic minerals with significant gravity differences.

Stable and precise mineral separation with a high handling capacity.

High efficiency with increased concentration ratio and recovery rate.

Adaptable feeding capacity with variability in concentration, granularity, and grade.

Easy installation with a compact footprint and straightforward operation.

Material quality featuring moisture resistance, rust protection, and corrosion resistance.

Advantages of being non-powered, lacking moving parts, and operating silently.

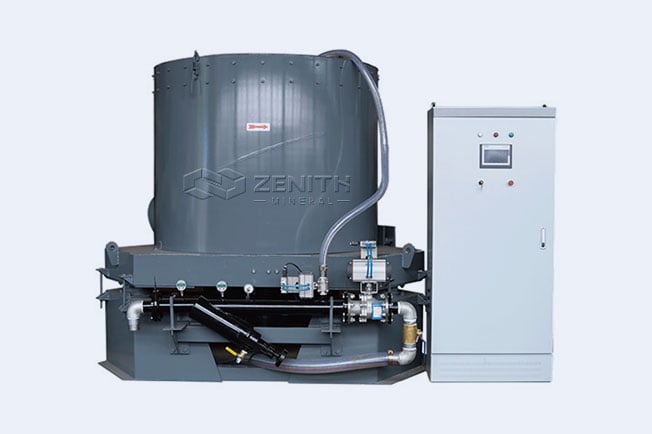

The SD Series Centrifugal Concentrator propels the feeding ore around under the high-speed rotation of its inner cone part. This rotation subjects the feeding ore to a centrifugal force dozens of times greater than gravity, amplifying the gravity difference of minerals by the same factor. The strong centrifugal force ensures that fine gold particles do not float on the water surface but rotate at the bottom of the separation tank. High-pressure backwashing water prevents mineral hardening, and high-pressure water expels light materials from the concentrator's separation tank, leading to effective beneficiation results on fine minerals. This centrifugal concentrator has demonstrated exceptional performance on gold ore, achieving a recovery rate of over 95% for free gold particles finer than 100 mesh.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.