The HPGR significantly enhances the capacity of the crushing system while reducing the consumption of electric power and steel balls in the ball mill.

Featuring a highly wear-resistant roller surface, excellent crushing ratio, increased availability, cost and investment savings, and flexible configuration, the HPGR is capable of processing various ores ranging from 50t/h to 2000t/h.

It offers several advantages, including a robust structure, a roller surface with high wear resistance, and high efficiency with energy-saving capabilities.

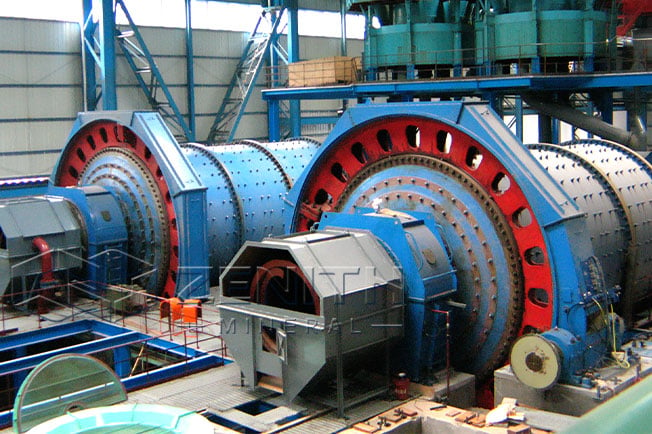

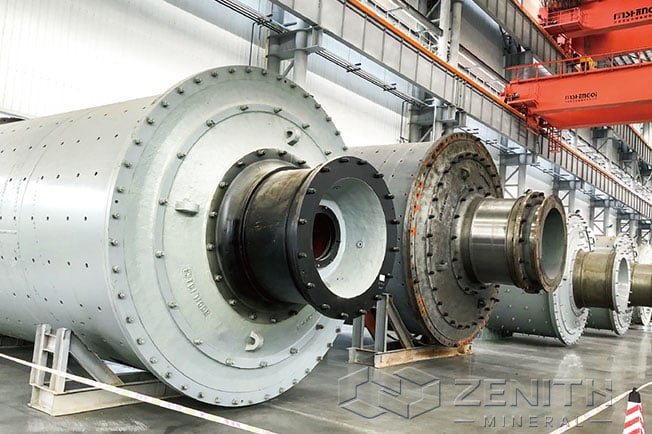

The ball mill is the crucial equipment for conducting pulverizing operations after materials are crushed, widely employed for crushing and grinding various ores or other grindable materials. In general, it is preferable to utilize an overflow ball mill for fine ore grinding fineness and a grate ball mill for coarse grinding. (This helps prevent adverse effects on sorting due to heavily milled materials.)

Featuring a large discharge opening, this equipment boasts a high production capacity.

By employing double row spherical roller bearings instead of sliding bearings, the transmission system significantly reduces friction, enables easy starting, and achieves energy savings of 20% to 30%.

The lining plate is constructed from lightweight and wear-resistant materials, ensuring easy replacement and excellent durability. This extends the overall equipment lifespan significantly.

The implementation of waveform lining plates increases the contact surface between the steel balls and the ore, enhancing grinding efficiency and reducing energy consumption.

The rod mill is loaded with steel bars as grinding media and comprises five parts: cylinder shell, feeding system, discharge system, main bearing, and transmission system. It is suitable for both dry and wet grinding to meet customer needs. Materials with a Moh's Hardness of 5.5-12 can all be handled by our mill.

Our new equipment, compared to the old rod mill with sliding bearings, can save you 10-20% in total energy consumption and improve production by more than 10%.

The expertly designed specifications ensure smooth operation with minimal over-crushing issues.

We have supplied numerous wet grinding rod mills to customers in the coal chemical industry, handling coal and petroleum coke materials for coal water slurry production.

The mill can be designed as primary level open circuit grinding equipment, suitable for various applications like manual stone sand, ore treatment plants, and chemical facilities.

Easy Installation and Access

As mineral resources evolve and beneficiation technology advances, the tower mill has emerged as a vital tool for effectively dissociating fine-grained paragenetic minerals. The tower mill is a vertically mounted fine grinding equipment with a spiral stirring device.

The equipment operates quietly, occupies minimal space, saves energy by 30%-50%, and significantly improves grinding efficiency.

Fully enclosed shell allows for indoor and outdoor installation and operation.

Modular stirring blade structure allows for separate replacement.

Inner wall wear-resistant liner made of magnetic material or grid provides material lining protection.

Large door opening structure on the cylinder's side facilitates on-site maintenance and repairs.

Innovative secondary sedimentation separation of feeding material ensures even size distribution control, increasing the proportion of qualified sizes.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.