ZENITH has rich experience in building stationary crushing plants for our clients. All capacities from 50-2000t/h are available here. Meanwhile, we can customize the crushing plants according to our clients' special requirements.

ZENITH has rich experience in building stationary crushing plants for our clients. All capacities from 50-2000t/h are available here. Meanwhile, we can customize the crushing plants according to our clients' special requirements.

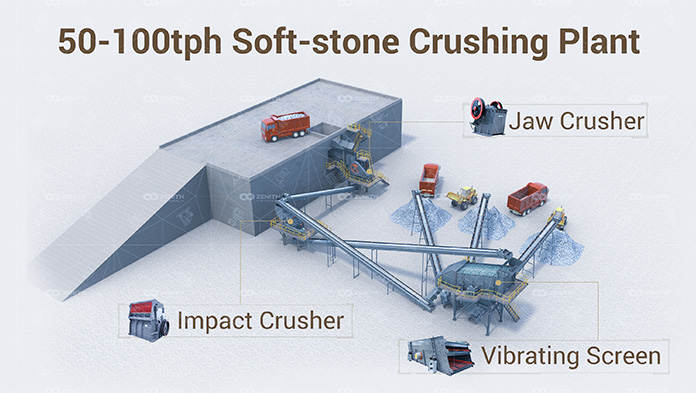

50-100t/h soft rock crushing plant are mainly constructed of jaw crusher for primary crushing, one impact crusher for secondary crushing, one vibrating screen and one vibrating feeder. This crushing plant is usually used for crushing limestone, gypsum and dolomite, etc. And benefit from the features of secondary crusher, the shape of aggregates is quite good.

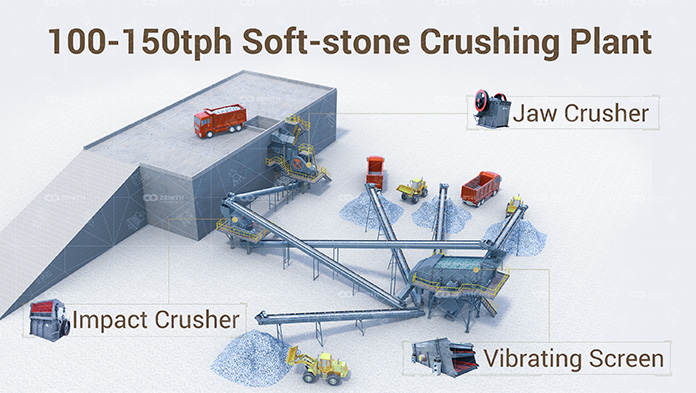

100-150t/h soft rock crushing plant is also mainly constructed of jaw crusher for primary crushing, one impact crusher for secondary crushing, one vibrating screen and one vibrating feeder. The difference with the small scale crushing plant is the model of crusher. And this crushing plant is also mainly used for crushing limestone, gypsum and dolomite, etc.

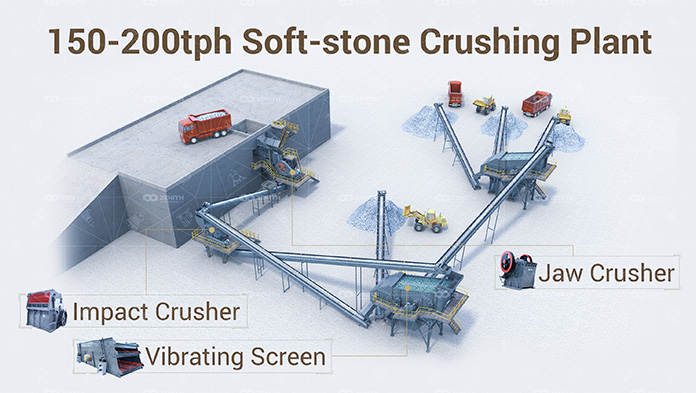

100-150t/h soft rock crushing plant mainly consists of jaw crusher for primary crushing, one impact crusher for secondary crushing, two vibrating screens and one vibrating feeder. Compared with the 150-200t/h crushing plant, the model of crusher is bigger and one screen is added, it just increases a little investment cost. And this crushing plant is also mainly used for crushing limestone, gypsum and dolomite, etc.

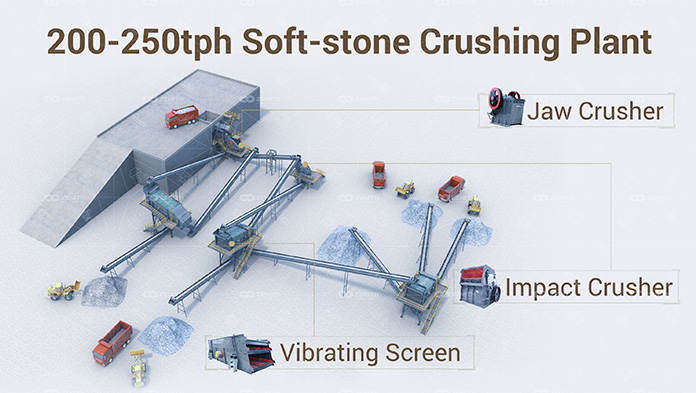

200-250t/h soft rock crushing plant mainly consists of one jaw crusher for primary crushing, one impact crusher for secondary crushing, three vibrating screens and one vibrating feeder. And this crushing plant is also mainly used for crushing limestone, gypsum and dolomite, etc. The most important feature of this plant is that the investment of this crushing plant design is quite low if it’s compared with other designs.

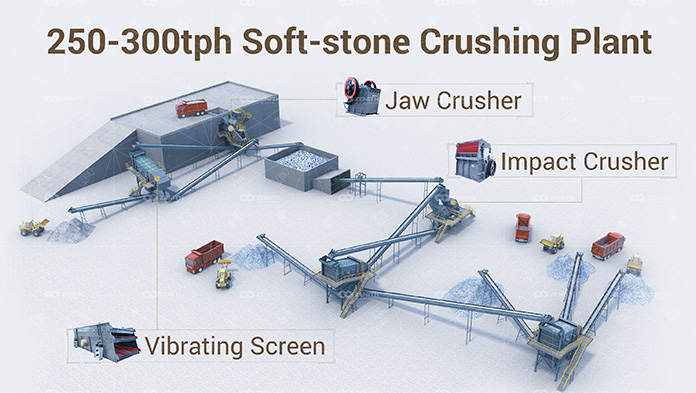

250-300t/h soft rock crushing plant is mainly made of one jaw crusher for primary crushing, two impact crushers for secondary crushing, three vibrating screens and two vibrating feeder. And this crushing plant is also mainly used for crushing limestone, gypsum and dolomite, etc. As one popular scale, this ZENITH crushing plant design is widely used in lots of countries and get high reputation from ZENITH customers.

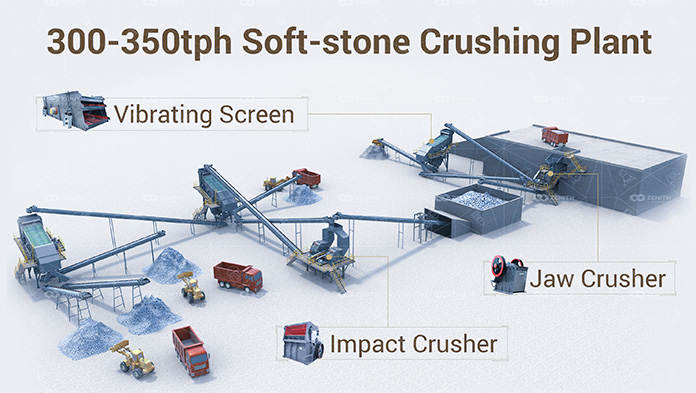

300-350t/h soft rock crushing plant is almost the similar with 250-300T/H crushing plant, it’s also mainly made of one jaw crusher for primary crushing, two impact crushers for secondary crushing, three vibrating screens, etc. And this crushing plant is also mainly used for crushing limestone, gypsum and dolomite, etc. The biggest difference is the model of the crushers; they are bigger than the 250-300T/H crushing plant.

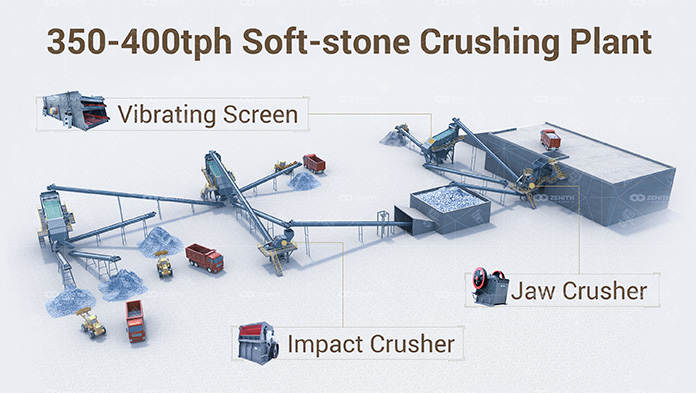

350-400t/h soft rock crushing plant is mainly made of one jaw crusher for primary crushing and one big model impact crusher as the secondary crusher. This impact crusher is the newest type CI5X impact crusher, it has higher capacity and better performance. In this way, the maintenance cost and the labor cost of the whole plant can be greatly reduced.

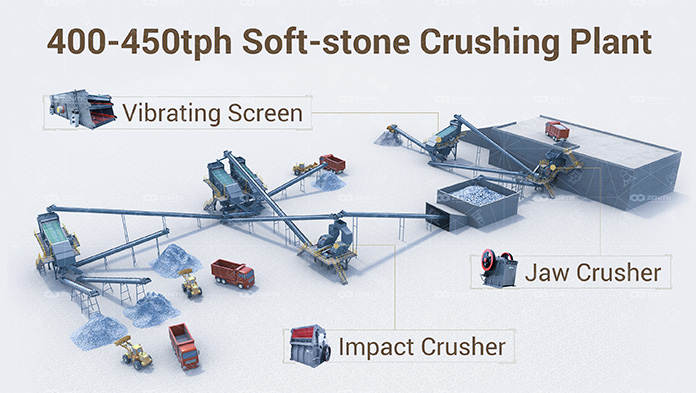

400-450t/h soft rock crushing plant mainly consist of one ZENITH PEW jaw crusher, two PFW impact crushers, which has been used in lots of quarries. Also, four vibrating screens and many vibrating feeders are necessary. Compared with some other designs, this crushing plant design has much more excellent performance and the capacity is quite stable.

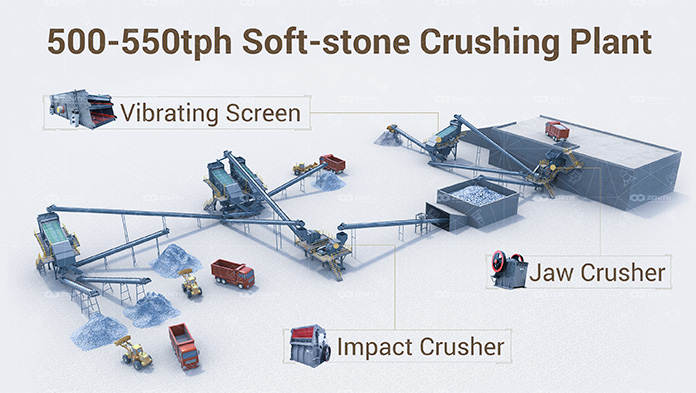

500-550t/h soft rock crushing plant mainly consist of one ZENITH PEW jaw crusher for primary crushing, one CI5X impact crusher for secondary crushing and one PFW impact crusher for third-stage crushing. The output size could be 0-5-10-20-31.5mm and they are adjustable according to different requirements. Also, the final aggregates shape is quite good.

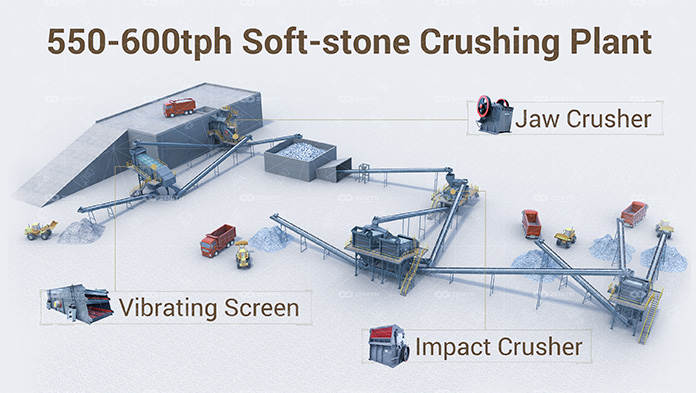

550-600t/h soft rock crushing plant is similar with 500-550T/H soft rock crushing plant. It’s also made of ZENITH PEW jaw crusher for primary crushing, one impact crusher for secondary crushing and one impact crusher for third-stage crushing. The output size could be 0-5-10-20-31.5mm and they are adjustable according to different requirements. Also, the final aggregates shape is quite good.

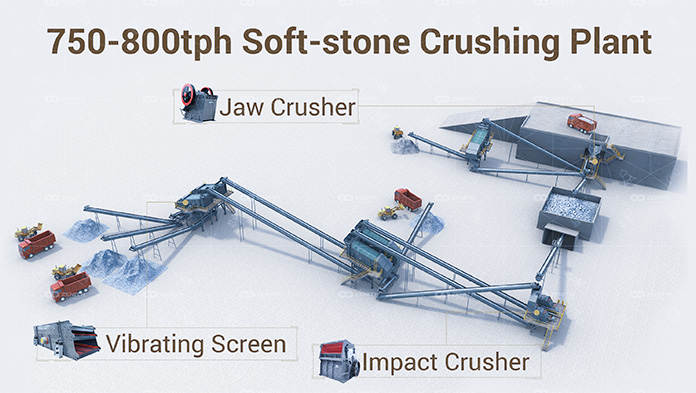

750-800t/h soft rock crushing plant mainly contain one C6X jaw crusher, two CI5X impact crushers and many vibrating screens and feeders. The output size could be 0-5-10-20-31.5mm and they are adjustable according to different requirements. Benefit from ZENITH good design, the performance of this plant is quite excellent, the capacity is stable and the aggregates shape is good.

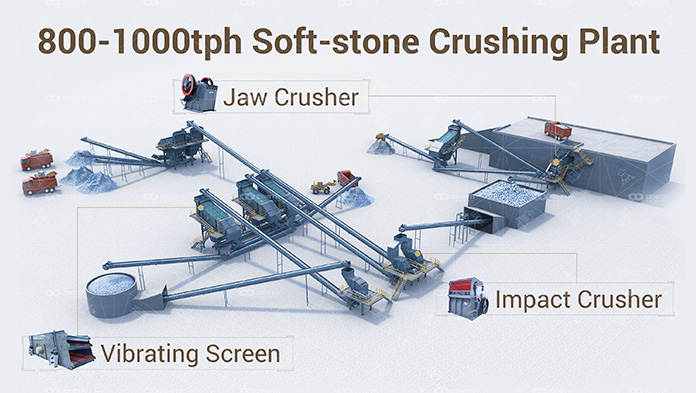

800-1000t/h soft rock crushing plant is one quite large scale plant, and the core problem of building this plant is that whether the capacity is able to meet the requirements. Well, the ZENITH crushing plant design, which is made of one C6X jaw crusher and three impact crushers and some other machines, solve the problem perfectly. Also, its performance has been proven in many quarries.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.