For those investors who want to find a grinding mill with high quality and low price should know that get what one pays for. A high-quality grinding mill's price must higher than lower-quality's. It depends on QUALITY. This article will show you how to choose a high-quality grinding mill in a reasonable price.

Different materials you need to process and demands of output size of materials determine what kind of grinding mill you should choose. In generally, the range of processing materials of grinding mills is large: limestone, calcite, dolomite, petroleum coke, gypsum, barite, marble, talc, pulverized coal, etc.

Different kinds of grinding mill have different input size, output size and production capacity. According to different technical design, it can be divided into verticalgrinding mill, Raymond mill and ultrafine grinding mill.

1. LM Vertical Grinding Mill

Input size: 0-70mm

Output size: 80-325 mesh

Capacity: 10-340t/h

LM Vertical Grinding Mill integrates medium crushing, drying, grinding, classifying and other functions into a whole. It is the ideal equipment in the grinding industry.

2. Raymond Mill

Input size: 0-35mm

Output size: 80-400 mesh

Capacity: 3-22t/h

Compared with the ball mill, it is a traditional choice for grinding powder, which covers a small area, is easy to adjust fineness, and the efficiency of air induction is increased from 62% to 85%.

According to continuous technical improvement, the raymond mill has been upgraded to the European TrapeziumGrinding Mill -- not only the feed size has been expanded to 0-50mm, but also the production capacity has been improved to the maximum of 50 tons. In addition, it also has low energy consumption, high efficiency and no dust.

3. XZM Ultrafine Grinding Mill

Input size: 0-20mm

Output size: 2500mesh

Capacity: 25t/h

It is suitable to grind the material with middle and low hardness, moisture below 6%, and the material should be non-explosive and non-flammable.

The processing capacity of different kinds of grinding mills is different. Users should request the technical engineer of the manufacturer to issue the processing plan according to their own needs, and then choose the suitable equipment based on the comprehensive investment and market. Specific kind of grinding mill can be online or leave a message to consult ZENITH's free technical personnel.

we explore the five key advantages of using a portable crusher plant in Kenya, illustrating how it effectively addresses local industry pain points and accelerates project success.

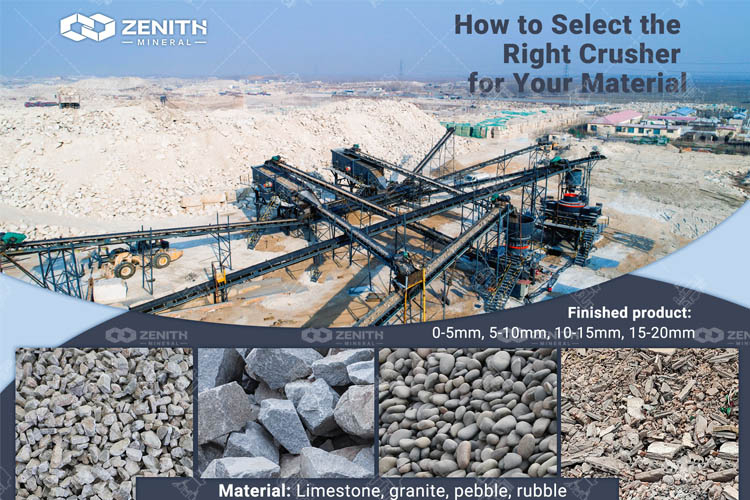

Discover how to pick the right crusher for soft, medium-hard, hard, or very hard rocks. Learn key factors like rock hardness, product shape, capacity & TCO to boost efficiency and cut costs in mining, construction & recycling.

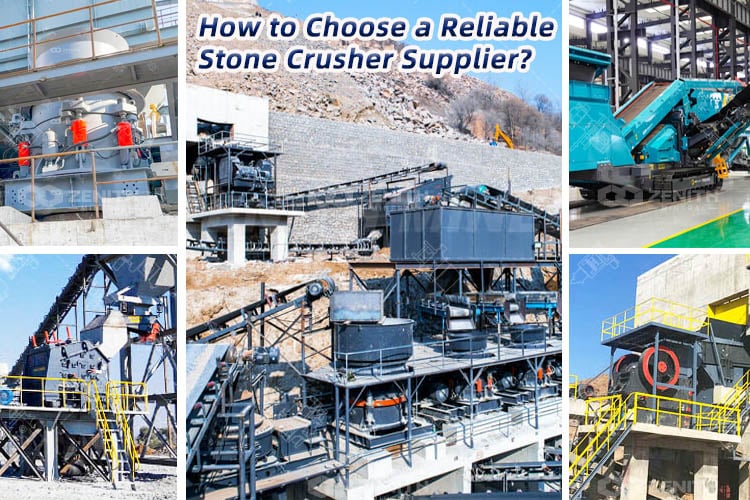

Choose a reliable stone crusher supplier with this professional guide. Learn key steps: assess needs, check reputation, product quality, after-sales support, and cost-efficiency for optimal operations

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.