Starting a quarry operation involves considerable planning and investment to turn natural rock resources into a profitable venture. The total startup costs will vary depending on factors like the size, site conditions, equipment needs and environmental requirements. However, most industry experts estimate that a basic quarry operation requires a minimum of $500,000 to $2 million in initial capital outlay.

Some of the major initial expenses include:

Starting a stone quarry requires such a large investment, so what are the important factors that you need to consider when setting up a new stone quarry business?

Procuring a suitable extraction site with viable deposit qualities is the first crucial step. Thorough geological surveys can identify reserves and assess stone quality. Overburden depth and thickness of commercial strata impact costs.

Access to transport infrastructure like roads is also important for hauling purposes. Local builders' merchants and construction projects indicate potential markets. Proximity to demand centers lowers distribution expenses.

Obtaining permits involves feasibility studies of environmental, social and economic impacts. Rehabilitation bonds cover projected restoration costs. Public hearings address community concerns over issues like noise, dust and traffic. Strict compliance with regulations maintains goodwill.

Extractive plans must align reserves with anticipated demand over the lifetime. Primary and secondary extraction zones should satisfy needs in a balanced manner preventing early depletion. Extraction rates and productivity levels determine overall viability.

Quarry face orientation and bench geometry optimize fragmentation while worker safety. Explosives use necessitates qualified blasting expertise. Water management using settling ponds prevents contamination. Load and haul cycle efficiency impacts costs.

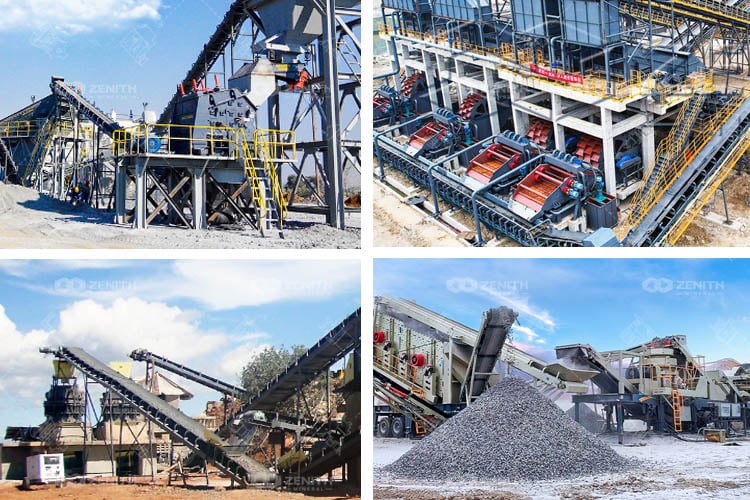

Crushing facilities reduce sizes for stockpiling, screening or direct sale. Jaw, cone or impact crushers suit different material properties. Portable units provide flexibility. Vibratory screens produce consistent gradations for asphalt, concrete and landscaping.

Conveyors transport across site. Stackers and reclaimers facilitate stockpile management. Mobile equipment like excavators, dozers and haul trucks uniformly distribute overburden and load vehicles. Telehandlers load trucks from stockpiles for dispatch.

Site roads capable of bearing heavy loads connect different work areas. Workshop facilities house equipment maintenance/repairs. Admin buildings provide offices, first aid, amenities. Fuel storage with dispensing ensures continuity. Security fencing and lighting deters trespassing.

Staff housing or allowance meets long-term needs. Hardstanding or shed areas temporarily stock contractor materials. Drainage works and sediment traps minimize impacts. Overall infrastructure meets production requirements yet causes minimal site disturbance.

Target markets comprise public works contracts, landscaping suppliers, homeowners/builders within distribution radius. Product range from aggregates to specialized stonewidens customer base.

Competition from existing suppliers must be considered. Introductory pricing slightly lower than competitors gains initial foothold before gradual inflation aligned to costs. Contracts for major projects boost revenue. Quality assurance builds long-term reputation.

Bank loan repayment projections require factoring variations in costs, production, revenues and market strength over the first 5-10 years. Break-even point estimates guide viability.

Insurances cover liabilities from accidents, machinery breakdown. Reclamation bonding funds restoration obligations on closure. Contractors' all risk coverage limits third-party exposure. Stockpile value insurance safeguards inventory.

With diligent planning and quality execution, new quarries have profitable long term potential if sustainably managed with community and environmental stewardship prioritized equally with financial returns. Perseverance amid initial challenges eventually leads to stability and success.

Starting a quarry business is a significant investment—but with the right planning, it can be a highly profitable venture in the booming construction materials industry. While upfront costs and regulatory hurdles may seem daunting, strategic decisions (like choosing scalable equipment or leasing land) can dramatically reduce risk and accelerate ROI.

Learn proven ways to reduce crushing plant operating costs, including equipment selection, energy efficiency, wear part control, and process optimization to lower cost per ton and improve ROI.

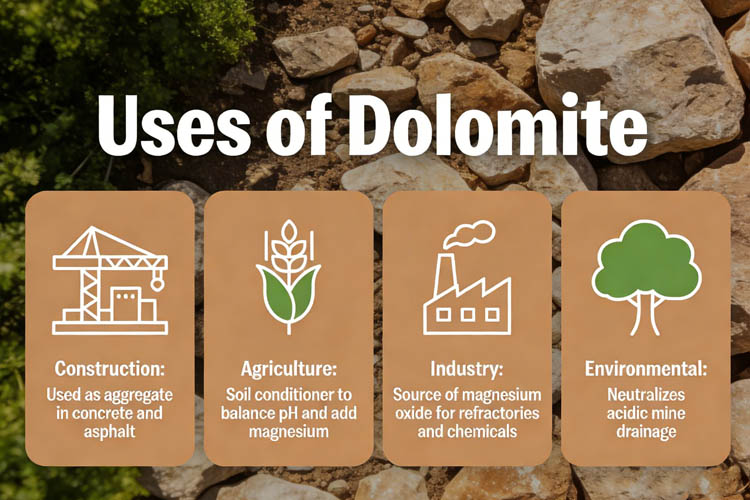

This article will explore 10 prominent uses of dolomite, shedding light on its versatility and highlighting its importance in today’s global economy.

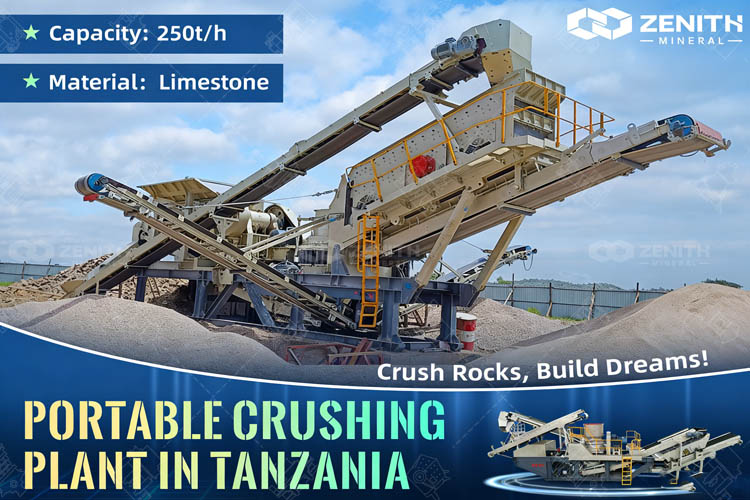

Discover the cost of portable crushing plants in Tanzania. Learn factors affecting price, capacity, mobility options, and how to choose the right solution for your mining or quarry project.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.