Jaw crusher and impact crusher are both frequent used crushing equipment in the market. But many people may have a limited understanding of them, especially those who are new to this industry. Here are the differences between jaw crusher and impact crusher in practical applications.

1)material hardness

Jaw crusher is suitable for crushing various soft and hard materials with compressive strength between 300-350Mpa. The models and specifications of ZENITH jaw crushers are all complete. There are coarse jaw crusher and fine jaw crusher for customers to choose, mainly used for the primary crushing operation of materials.

Impact crusher is suitable for crushing materials with medium& soft hardness and small brittleness, such as limestone. If the materials are hard, they can cause significant damage to wear-resistant parts and shorten their service life.

Impact crusher is widely used in all kinds of coarse, medium and fine crushing operations, the discharge port can adjust the particle size arbitrarily, in order to meet the needs of different customers.

2) material particle size

Jaw crusher is generally used for crushing large materials smaller than 1200mm (depending on the equipment model). It has wide application in mines and sand and gravel production lines.

Impact crusher is used to process small and medium-sized materials.

The obvious difference between jaw crusher and impact crusher is the difference in structure and working principle. The working mode of jaw crusher is a curved extrusion type, and the material is crushed by compression in the crushing chamber composed of a moving jaw and a fixed jaw.

Impact crusher adopts impact crushing principle, where the material is repeatedly impacted and crushed between the rotor (plate hammer) and the impact plate.

As we know, in crushing, sand making, beneficiation and other production lines, jaw crusher is the most commonly used primary crushing equipment for coarse crushing.

Impact crusher is generally used as secondary or tertiary crushing equipment for medium and fine crushing. Sometimes, impact crusher can also be used as coarse crushing equipment when the raw material is soft or has low hardness.

Jaw crusher and impact crusher have different production capacities.

The max production capacity of ZENITH C6X series jaw crusher can reach to 1500t/h.

The max production capacity of ZENITH CI5X series impact crusher can reach to 2000t/h.

Of course, there are also many other types of jaw crusher and impact crusher for customers to choose. They have different production capacities, meeting different production requirements of customers.

Jaw crusher, as coarse crushing equipment, has larger discharge fineness, usually below 300-350mm (depending on the model).

Impact crusher, as medium or fine crushing equipment, naturally has smaller discharge fineness.

Here, we should notice that due to different material properties, the discharge fineness will also be different.

The grain shape of products from jaw crusher is not ideal and there is high content of needle-like particles. Impact crusher is a product in the crushing equipment that has good discharge grain shape and fewer edges of the final product, and its particle size is also better than cone crusher.

Therefore, in actual production, we often adopt impact crusher after jaw crusher for shaping.

Generally speaking, many manufacturers have higher sales and transaction volumes of jaw crusher due to price. Secondly, jaw crusher is more traditional crushing equipment that can meet users' application requirements in terms of performance, quality, power consumption, and other aspects. This cost-effective device is more likely to attract users' attention.

When selecting crushing equipment, we should choose the proper jaw crusher or impact crusher according to production requirements in order to achieve ideal production capacity and benefits.

And if you do not have a clear plan about the production, contact ZENITH for free. The professional engineers will help you configure the production line and recommend the most suitable crusher for you!

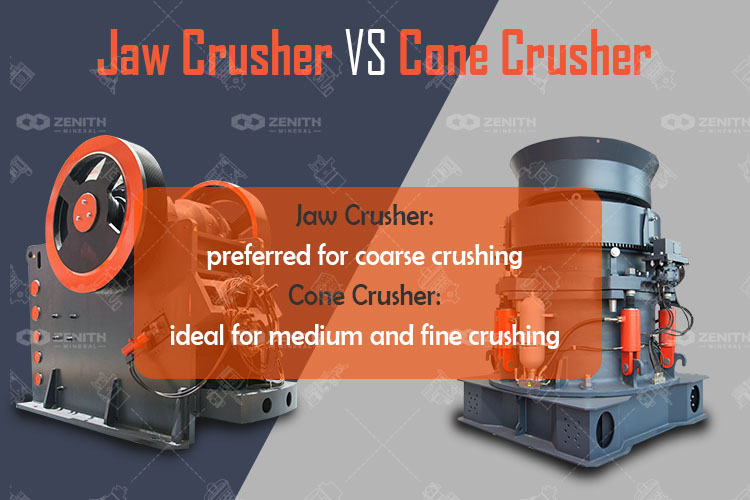

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

Jaw crushers are widely used in mining, construction, and infrastructure industries as primary and secondary crushers. They are classified into three types base

In general, impact crushers both vertical shaft (VSI) and horizontal shaft (HSI), the main difference from the cone crusher is the type of crushing force. The i

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.