When it comes to purchasing replacement parts for equipment, operators often face a choice between OEM parts and aftermarket alternatives. While aftermarket parts seem appealing due to potentially lower costs, OEM parts offer significant advantages in terms of quality, reliability and longevity. This article examines the key benefits of choosing OEM parts over aftermarket options.

OEM, or "original equipment manufacturer", refer to parts and components manufactured by the same brand that produced the original equipment. These parts are designed and tested to the manufacturer's specifications to ensure perfect fit and function within the machine. Unlike aftermarket parts, OEM parts use the same materials and production processes as the original components. They also benefit from the R&D invested by the manufacturer in developing durable, high-performance parts.

During design, OEM conduct failure mode analyses to identify weaknesses. Materials selection undergoes rigorous testing for durability and corrosion resistance in target environments. Prototypes face destructive testing to validate designs can withstand stresses.

Production involves quality control at each stage. Advanced systems monitor adherence to tight tolerances. Automation and manual inspections complement each other for comprehensive defect detection.

Through integrated development and manufacturing under a single quality system, OEM ensure product compatibility with parent equipment down to micrometric accuracies. Installation requires no modifications, maintaining system integrity.

System compatibility underpins equipment dependability essential for operations. Only OEM empower predictions of outcomes from replace-and-run installations. Alternative suppliers cannot certify performances given unknown manufacturing variances.

Substituting even one part risks compromising this synergy. Marginal errors may cause premature wear, inefficiency or even catastrophic failures. To OEM, matching original specifications is the only way ensuring designs perform as intended.

Reliability directly affects profitability through lower costs. OEM parts sustain rated service lives with negligible downtime, versus replacing subpar copies prematurely. Quality also precludes liability for collateral damage due to part failures.

Assurance of consistent supplies maintains production schedules rigorously. Regional warehousing networks support emergencies efficiently. Comprehensive warranties cover defect costs, amortizing initial premiums credibly.

One of the main advantages of OEM parts is the assurance of compatibility in dimensions, design tolerances and specifications. They are engineered precisely for plug-and-play replacement to maintain the equipment's factory design standards. This ensures optimal functionality without any modifications needed.

In contrast, aftermarket parts made by third parties may have marginal tolerances. Small dimensional deviations could cause vibrations, premature wear or inefficient operation over time. The quality of materials used is also uncertain, as aftermarket manufacturers may substitute cost-saving materials without thorough testing.

OEM conduct extensive testing and real-world trials before releasing parts. This testing regime guarantees OEM parts will perform as intended without unexpected failures. Their design is honed to maximize durability based on years of equipment design and field experience.

Aftermarket components lack this refinement process. Without replicating the OEM's rigorous testing protocols, aftermarket parts could contain latent defects only revealed after prolonged usage. They also may not withstand the same stress levels or harsh operating conditions as designed-for-purpose OEM parts.

Leading OEM back their parts with comprehensive warranties against defects. This provides recourse if a component fails prematurely due to manufacturing or material faults. Most OEM warranties also cover labor costs for replacement installation during the coverage period.

Technical support is another valuable advantage of buying OEM. Factory-trained technicians possess in-depth knowledge of all systems, enabling fast troubleshooting. OEM parts manuals and installation guides ensure proper replacement procedures. This mitigates risks from errors during DIY overhauls with aftermarket components.

While priced marginally higher initially, OEM parts deliver long-term cost savings through reliable performance, minimal downtime and extended component lifespans. Aftermarket substitutes needing premature replacement multiply total expenditure over the equipment's working life. Reliability also prevents expensive downtime from broken parts stalling operations.

While aftermarket components seem appealing at face value, a lifetime cost analysis emphatically favors the Total Cost of Ownership benefits from OEM parts. Their assurance of precise fit, robustness through original manufacturing quality processes and backing by comprehensive warranties and technical help, delivers much greater value and efficiency enhancing returns in the long run. Choosing OEM therefore secures equipment reliability and optimized performance for maximum profitability over the equipment's working life.

Stone crushers are machines designed to reduce large rocks into smaller rocks, gravel, or rock dust. They are commonly used in the mining, construction, and recycling industries.

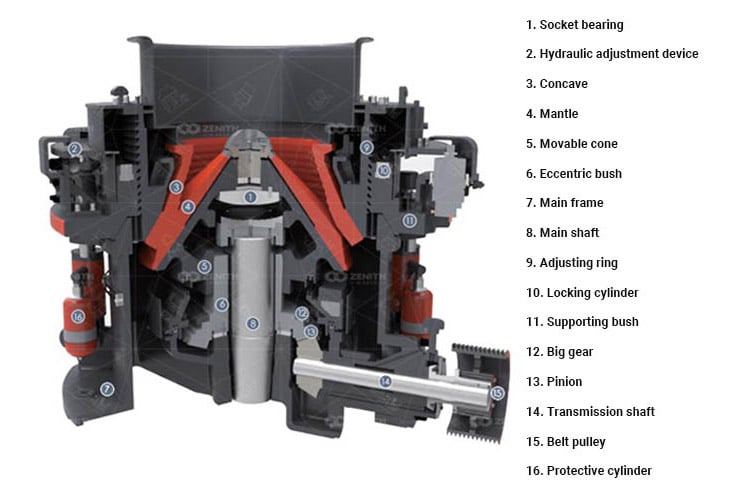

Our HPT series cone crusher uses advanced automation and componentry for high-production applications, understanding key cone crusher parts aids operation and maintenance.

Discover the key factors to consider when purchasing mobile crushers and screens in Malaysia. From material characteristics to operational costs, ensure you make an informed decision for optimal productivity and efficiency.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.