Quartz is one of the most abundant minerals on Earth. It ranks a seven out of 10 on the Mohs scale, which determines the hardness of a mineral, which means that it can be very difficult to crush.

Quartz is found in various geological environments, including igneous, metamorphic, and sedimentary rocks. Major sources of quartz include:

Quartz is crushed in order to separate out gold deposits often found inside. The crushed mineral can also be used for other industrial refining applications.

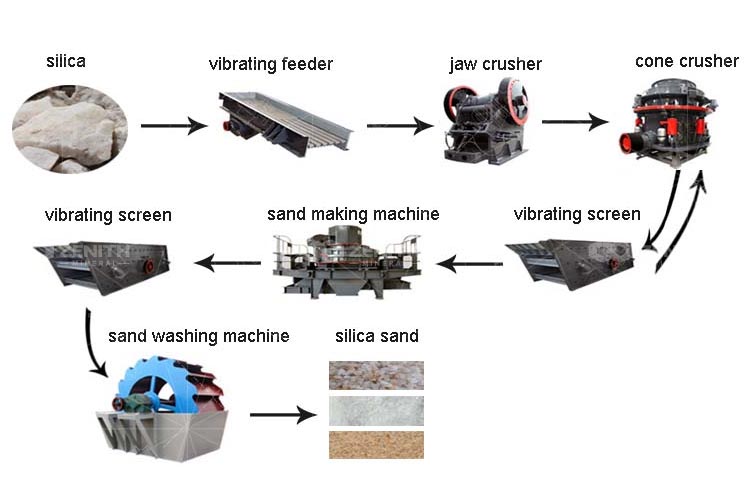

Quartz is a relatively hard mineral. The crushing can be processed in three steps to reduce the quartz material into small particle size for final application or further processing: primary crushing, secondary crushing and tertiary crushing.

The feeder or screens separate large boulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher. The stone that is too large to pass through the top deck of the scalping screen is processed in the secondary crusher. Tertiary crushing is usually performed using cone crushers or other types of impactor crushers.

The first step in quartz processing is primary crushing, which involves breaking down large quartz rocks into smaller pieces. This is typically achieved using:

Jaw Crushers: These machines crush the quartz by applying compressive force. The material is fed into the jaw chamber, where it is crushed between a fixed and a moving jaw.

After primary crushing, the material undergoes secondary crushing to achieve finer particle sizes. This stage may involve:

Cone Crushers: These crushers use a rotating cone to crush the quartz further. They are particularly effective for producing uniform particle sizes and are suitable for hard materials.

For applications that require very fine quartz particles, tertiary crushing may be necessary. This can involve:

Impact Crushers: These machines utilize impact forces to break down materials. They are effective for producing fine aggregates and are often used in the final stage of crushing.

Once the quartz has been crushed to the desired size, it is screened to separate fine particles from larger ones. Screening equipment includes:

Vibrating Screens: These screens use vibration to separate particles based on size. They are essential for ensuring that only the desired particle size is sent for further processing.

Washing is often necessary to remove impurities from quartz sand. Equipment includes:

Sand Washers: These machines wash away clay, silt, and other impurities, ensuring the purity of the final product.

Hydrocyclones: Used for separating fine particles from the washing process, hydrocyclones are effective in improving the quality of quartz sand.

To optimize the performance of quartz crushing plant, several best practices should be followed:

A thorough cost analysis is essential for evaluating the feasibility of a quartz crushing processing plant. Considerations include:

Evaluate the potential ROI by analyzing production capacity, market demand, and selling prices for processed quartz products. A well-planned operation can lead to significant profits over time.

The quartz crushing processing plant is a vital component in the production of high-quality quartz products. By understanding the properties of quartz, optimizing the crushing process, selecting the right equipment, and following best practices, operators can ensure the efficiency and effectiveness of their plants. As market demands evolve, staying informed about industry trends and advancements will position quartz processors for long-term success in a competitive landscape. By embracing innovation and sustainability, quartz crushing processing plant can meet the growing demands of various industries while minimizing their environmental impact.

From the perspective of development process, silica sand is widely used in glass, casting, ceramics and refractory materials, metallurgy, construction, chemical industry, plastics, rubber, abrasives and other industries.

This article delves into the world of quartz grinding machine, exploring their types, key features, and applications across industries.

If you want to know about the profit, you must first understand the cost composition in the silica sand washing plant.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.