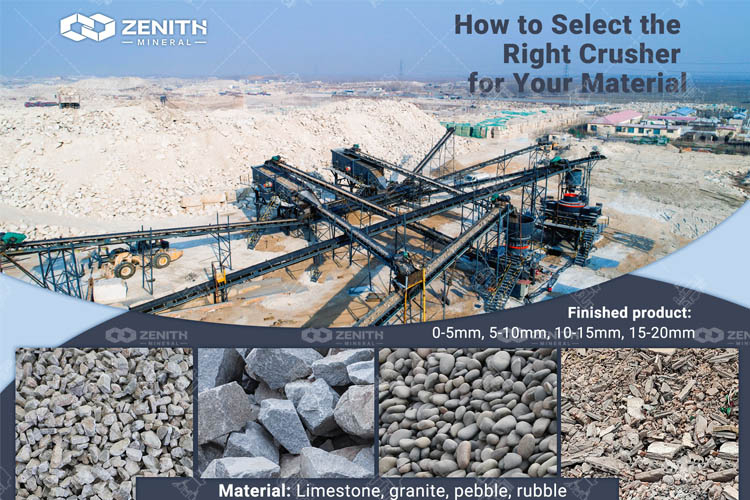

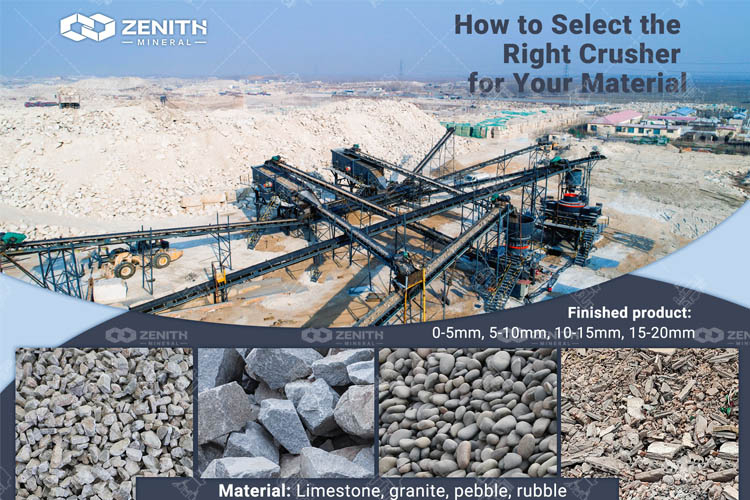

Soft Rock or Hard Ore? How to Select the Right Crusher for Your Material

Crushing rock materials is a fundamental process in industries such as mining, construction, aggregate production, and recycling. One of the most critical aspects of this process is selecting the appropriate stone crusher based on the hardness and characteristics of the material being processed. Different types of crushers are better suited for different rock materials, and using the wrong crusher can lead to inefficiency, excessive wear and tear, and increased operating costs.

This comprehensive guide will explore the different types of crushers and how they are best applied to rocks of various hardness levels. We will discuss the key characteristics of different rock types and how they influence the choice of crushers, along with recommendations for the most effective machines to use for each material type.

Understanding Rock Hardness

Rock hardness is a measure of a material’s resistance to deformation, indentation, and scratching. It is essential to know the hardness of the rock you're working with, as this determines the wear and tear on your equipment and the type of crusher best suited for the task. Hardness can be broadly classified into the following categories:

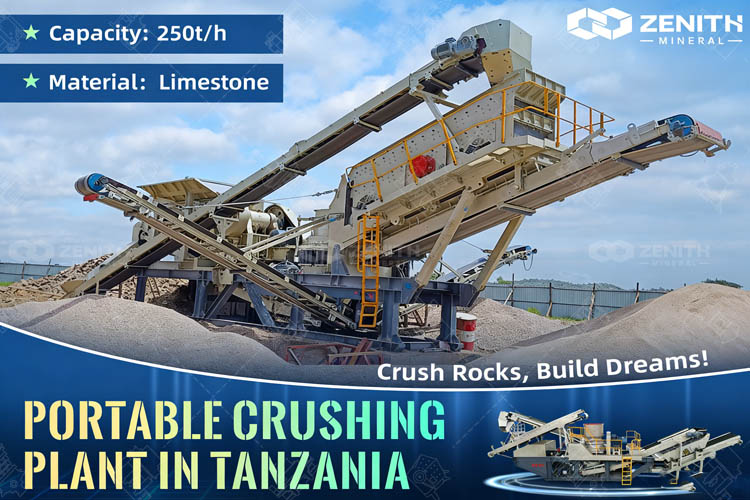

- Soft rocks: These materials include limestone, chalk, gypsum, and clay. They have low resistance to crushing and are generally easier to process.

- Medium-hard rocks: These materials include sandstone, shale, and certain types of granite. They are harder than soft rocks but still manageable for many crushers.

- Hard rocks: These materials include quartzite, granite, basalt, and some types of iron ore. They are highly resistant to crushing and require specialized crushers to achieve desired material sizes.

- Very hard rocks: These include ultra-hard minerals like diamond-bearing rocks or extremely compacted materials such as some basalt varieties. These materials are challenging to crush and require the most robust crushing equipment available.

In the following sections, we will discuss which crushers are best suited for each of these hardness categories.

Crushers for Soft Rocks

- Examples: Limestone, chalk, marl, gypsum, certain shales, reclaimed asphalt pavement (RAP).

- Characteristics: Low compressive strength (< 150 MPa), low Mohs hardness (< 5), low to moderate abrasiveness.

Primary/First-Stage Crushing:

- Jaw Crushers: Highly effective. Their simple, robust compression design efficiently reduces large feed sizes. A good, cost-effective choice.

- Impact Crushers (Primary Horizontal Shaft Impactors - HSI): Excellent choice where product shape is a priority. They deliver high reduction ratios and produce a well-shaped, cubical product in a single stage, often eliminating the need for secondary crushing in softer materials. Their high-speed impact breakage is very efficient on brittle, less abrasive rock.

Secondary/Tertiary Crushing:

- Cone Crushers (for secondary): Can be used but may be over-engineered for soft rock, leading to higher capital and wear costs than necessary.

- Impact Crushers (Secondary HSI or Vertical Shaft Impactors - VSI): The preferred choice. Secondary HSIs further refine size and shape. VSI crushers are unparalleled for tertiary crushing and shaping of soft to medium-hard materials, producing premium, cubical aggregates for concrete and asphalt.

- Roll Crushers: Suitable for precise size reduction with minimal fines generation in secondary applications, especially for mid-hard coals and industrial minerals.

Crushers for Medium-Hard Rocks

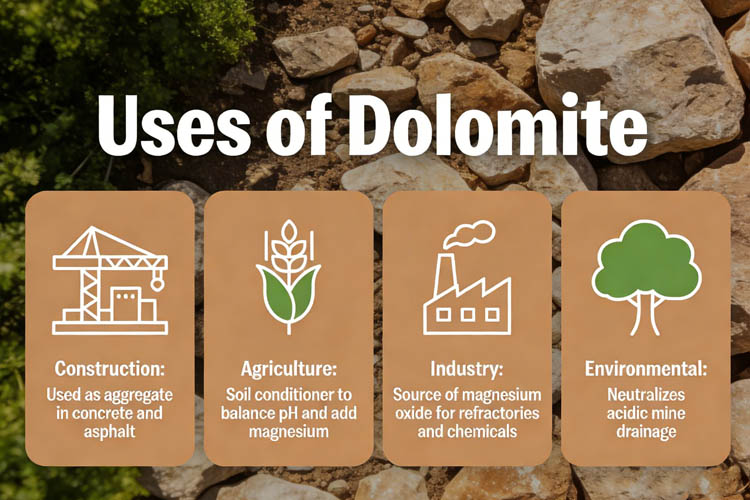

- Examples: Dolomite, sandstone, conglomerate, some phyllites, greywacke.

- Characteristics: Compressive strength 150-250 MPa, Mohs hardness 5-6, moderate quartz content leading to measurable abrasiveness.

Primary/First-Stage Crushing:

- Jaw Crushers: The workhorse for primary crushing of hard rock. Their robust, slow-compression action is ideal for high-strength materials. Deep crushing chambers and optimized kinematics handle tough, blocky feed.

- Gyratory Crushers: For very high-capacity primary plants (> 1000 tph). They offer higher throughput than jaw crushers and are more economical at scale but have higher initial costs and installation complexity.

Secondary/Tertiary Crushing:

- Cone Crushers: The dominant and most efficient technology for secondary and tertiary crushing of hard, abrasive rock. Modern hydrocone-type crushers excel here. Key advantages include:

- High Pressure, Inter-Particle Breakage: The rock-on-rock crushing action in the crowded chamber is exceptionally efficient and wear-conscious.

- Adaptability: Adjustable eccentric throw and CSS (closed-side setting) allow optimization for capacity or product fineness.

- Wear Protection: Robust mantle and concave designs in high-chrome or manganese steel withstand abrasion.

- Impact Crushers: Use with caution. Standard HSIs will experience prohibitive wear costs on abrasive rock. However, specialized, heavy-duty HSIs with innovative rotor designs and highly wear-resistant metallurgy (e.g., ceramic composites) can be viable for specific, less abrasive hard-rock applications where shape is paramount.

Crushers for Hard Rocks

- Examples: Granite, basalt, trap rock, quartzite, taconite, many metal ores (e.g., copper, iron).

- Characteristics: Compressive strength > 250 MPa, Mohs hardness > 6, high quartz or mineral content causing severe abrasiveness.

Primary/First-Stage Crushing:

- Jaw Crushers (Heavy-Duty): Equipped with thick, high-integrity plates and robust frames. A reliable choice, though wear part replacement frequency will be high.

- Gyratory Crushers: Often the optimal primary solution for large-scale hard-rock mining and high-tonnage aggregate quarries. Their ability to handle very large feed and deliver consistent, high throughput with lower sensitivity to abrasion (due to massive liners and continuous action) makes them cost-effective in the long run.

Secondary/Tertiary Crushing:

- Cone Crushers (Specifically Designed for Abrasive Duty): The only viable choice for efficient, controlled size reduction. Look for features essential for this duty:

- High-Pressure Grinding Rolls (HPGR) as an alternative/pre-crusher: Increasingly used in hard ore processing before a ball mill, they are highly energy-efficient but not a direct replacement for cone crushers in aggregate production.

- Advanced Liner Profiles and Metallurgy: Special alloy steels, manganese with micro-alloying, and even chrome-white iron liners for extreme abrasion.

- Automated Liner Wear Compensation: Systems like ASRi™ (Automatic Setting Regulation) are critical to maintain consistent product gradation and optimize crusher utilization as wear occurs.

- VSI Crushers with Rock-on-Rock Configuration: For the final shaping stage of hard, abrasive rock, a true rock-on-rock VSI (where the rotor accelerates material into a stationary rock shelf) can be used. Wear costs are transferred to the anvils and rotor tips, which can be more economical than trying to shape with cones alone, but it requires careful circuit design.

Crushers for Very Hard Rocks

- Examples: Sticky, clayey ores; wet/frozen materials; recycled concrete with rebar (C&D waste).

- Characteristics: Challenges are not primarily hardness but related to moisture, plasticity, or contamination.

Primary Crushing:

- Jaw Crushers: Tolerant of variability but can experience packing/choking with sticky material.

- Impact Crushers (with Special Features): Often superior for materials with clay. The high-speed impact action can help break up agglomerations. Non-clog designs with large feed openings and hydraulic adjustment for clearing are key.

- Hybrid/Specialized Crushers: Roll Crushers can handle sticky materials well. Feeder-Breakers or Sizer Crushers are designed specifically for wet, sticky ores in mining.

The Decision Framework: Beyond Simple Hardness

A professional selection process integrates hardness with other critical factors:

- 1. Feed Size and Desired Product Size (Reduction Ratio): Jaw and gyratory crushers offer the largest initial reduction. Cone crushers provide intermediate ratios. Impact crushers and VSIs offer the highest reduction ratios in a single stage for suitable materials.

- 2. Required Product Shape: For high-value aggregates (chips for asphalt, concrete), product cubicity is paramount. Impact Crushers (HSI & VSI) are the definitive shape-makers for materials they can process economically. Cone crushers, while improving, typically produce more elongated particles.

- 3. Capacity Requirements (TPH): Gyratory for >1000 tph primary. Large jaw and cone crushers for 500-1000 tph. HSIs and smaller cones for lower capacities.

- 4. Operational Context (Mobile vs. Stationary): Mobile plants prioritize flexibility. Jaw/Impact combos are common for mobile hard-rock applications. Cone crushers are central to stationary high-tonnage plants.

- 5. Total Cost of Ownership (TCO): Calculate: Capital Cost + (Wear Part Cost per ton Annual Tonnage) + Energy Cost per ton + Downtime Cost. For hard, abrasive rock, a more expensive cone crusher with lower per-ton wear costs will always outperform a cheaper impact crusher with rapid wear part failure.

There is no universal "best" crusher. The optimal selection is a precise engineering match between the rock's inherent properties—with hardness and abrasiveness at the core—and the crusher's breakage mechanics and design robustness.

- For soft to medium-hard, shape-sensitive materials, the crushing circuit should be dominated by Impact Crusher technology (HSI & VSI).

- For medium-hard to very hard, abrasive materials, the circuit's heart must be a robust Jaw or Gyratory primary crusher feeding into efficient, wear-optimized Cone Crushers for secondary/tertiary stages.

- VSI rock-on-rock technology can be judiciously applied as a final shaping stage even for hard rock, offering a trade-off between shape and wear cost.

The most successful operations partner with equipment suppliers who offer not just machines, but application expertise, realistic test data, and sophisticated simulation tools to model performance and wear before investment. By systematically analyzing material characteristics and aligning them with the correct crushing principles, operators can build a circuit that delivers maximum yield, quality, and profitability over its entire lifecycle.