Impact crusher is a use of impact energy to break the material crushing machine, when the machine work, driven by the motor, the rotor rotates at high speed when the hammer plate material into the work area, and the plate on the rotor impact crusher hammers,counter means after the crushing is thrown again, and then bounced back plate and from the counter area to re-crushing hammer on the liner, this process is repeated, gravel material into the descending one, two, three, cavities repeat countercrushing, until the material is crushed to a desired particle size, it is discharged from the discharge port.Adjust the gap between the rotor and the frame counter can achieve the purpose of changing the particle size of materials and material shape.

In the run counter Sand should pay attention to the following situations occur.

1, bearing temperature is too high

When the counter Sand occurred in operation bearing temperature phenomenon, we need to inspect the equipment, first look at whether grease is reduced if the reduction should be promptly replaced, and then check the bearings, bearings and cleaningreplacement work, so the bearing temperature will be reduced.

2, the operation of the device, vibrations very severe crushing chamber

If this occurs, the device should be checked immediately, see if it is a foreign body into the crushing chamber, check for loose lining wear lining and in some cases, timely replacement of broken parts.

3, the particle size is too large

Hammer and liner board to see if severe wear, if badly worn must be promptly replaced, the method is further adjusting the position of a frame counter, it is possible to ensure that the material particle size.

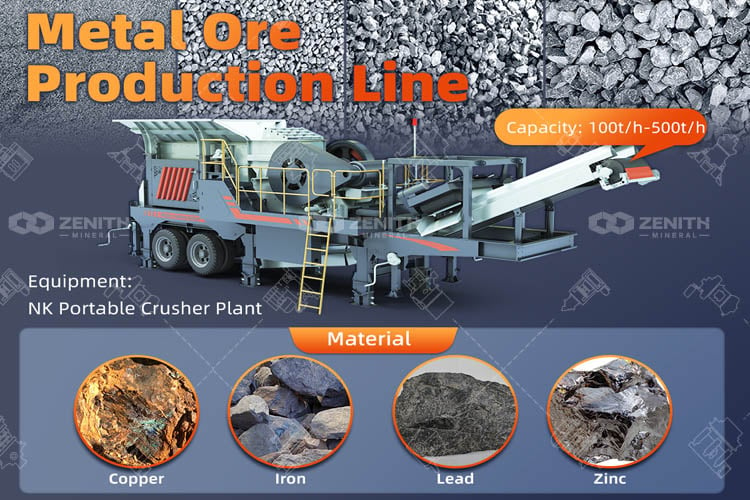

The NK Portable Crusher Plant is a powerful asset in the metal ore production line, offering a combination of high capacity, mobility, and advanced control systems.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

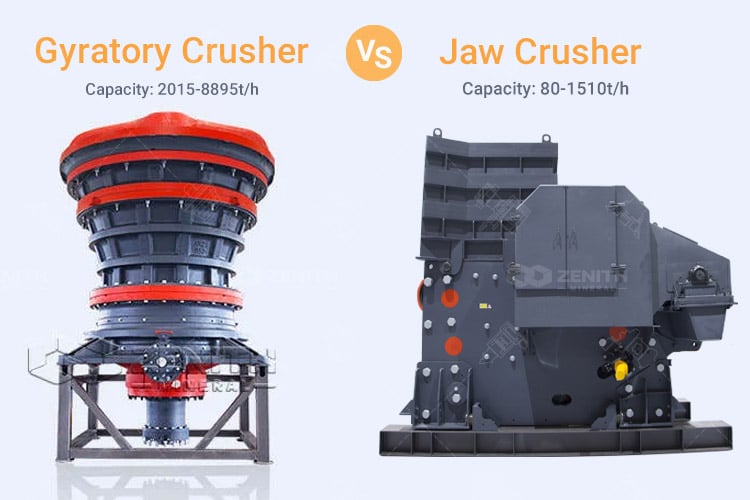

This article explores the key differences between gyratory crusher and jaw crusher, including their design, working principle, applications, capacity, maintenance and operating costs.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.