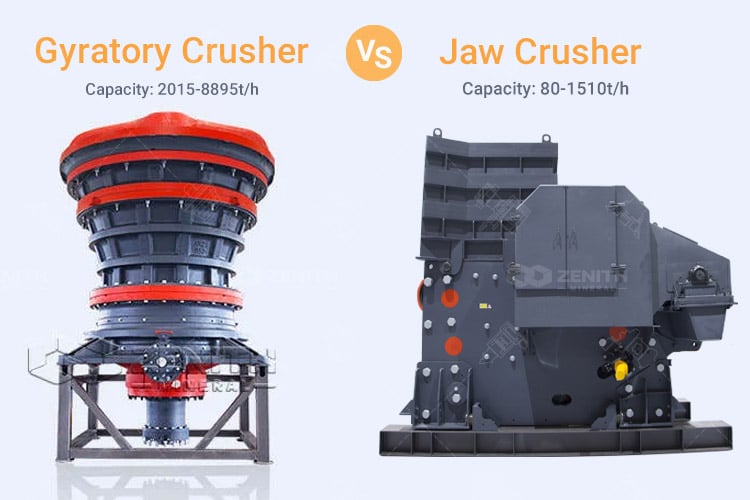

Gyratory crusher and jaw crusher are two of the most commonly used types of primary crusher in the mining and aggregate industries. While they serve the same fundamental purpose of reducing large rocks into smaller sizes, they operate in different ways and have distinct characteristics. This article explores the key differences between gyratory crusher and jaw crusher, including their design, working principle, applications, capacity, maintenance and operating costs.

Gyratory crusher is characterized by a conical head that gyrates within a stationary bowl. This design allows for continuous crushing, as the material is fed into the top and crushed between the mantle and the concave. Gyratory crusher is typically used for primary crushing in large-scale operations due to their high capacity and ability to handle hard materials.

Jaw crusher operate by compressing materials between two jaw plates—the movable jaw and the fixed jaw. The movement of the movable jaw creates a compressive force that crushes the material. Jaw crusher is versatile and can be used for both primary and secondary crushing, making them suitable for a wide range of applications.

In summary, both gyratory crusher and jaw crusher have their unique advantages and disadvantages. Gyratory crusher excel in high-capacity, primary crushing applications, while jaw crusher offer versatility and lower operational costs. The choice between the two depends on specific project requirements, including material type, size, and operational goals. Understanding the differences between these two types of crusher is essential for selecting the right equipment for your crushing needs.

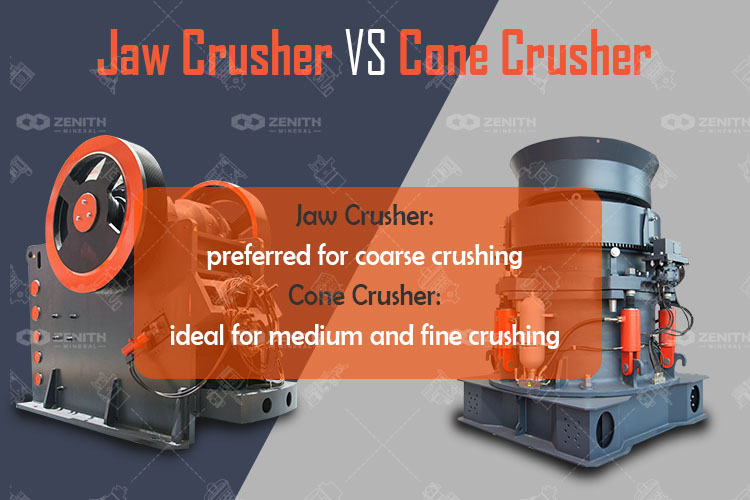

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

Jaw crusher and impact crusher are both frequent used crushing equipment in the market. Here are the differences between jaw crusher and impact crusher in practical applications.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.