Inside the mill, different parts play different roles and jointly assist the smooth progress of production. If the phenomenon of part deformation occurs, it will cause the production of a certain link to fail, which will cause the phenomenon of equipment shutdown. Therefore, we must reduce the deformation of the machine parts. Here is how to reduce the deformation of the mill parts.

First, the design must be reasonable

When designing the mill and its parts, we must consider the strength and rigidity of the parts, as well as the problems that may occur during the manufacturing, assembly, and use of the parts, and the various parts must be reasonably arranged when the equipment is installed To improve the force of the part, this can reduce the deformation of the part. In addition, when designing the part, it is necessary to ensure that the wall thickness of the part is uniform and reduce the temperature difference during thermal processing, so as to achieve the effect of reducing part deformation;

Second, Careful manufacturing

When customizing the blank manufacturing process of the mill, we must pay attention to the problem of deformation and take corresponding measures to reduce the residual stress of the blank. In the subsequent processing, we must arrange enough procedures to eliminate internal stress and strive to reduce the number of parts in the part. Residual internal stress. In the process of milling machine, roughing and finishing are divided into two processes, and a period of storage is set aside in the two processes, which is beneficial to eliminate internal stress and reduce the causes of parts deformation;

Third, warranty repair

Because the deformation of the parts cannot be avoided when the mill is in use, the equipment can not only check the wear of the mating surface during overhaul. The mutual position accuracy must also be carefully checked and repaired. In order to achieve this effect, the mill During overhaul, a reasonable maintenance standard should be worked out, and a simple, reliable, and easy-to-use special measuring tool and special tooling should be designed. In addition, a positioning reference should be selected reasonably during overhaul. Processing or pressure processing techniques, measures must also be taken to reduce stress and deformation;

Fourth, fair use

In the use process, if the operation is not reasonable, it is an important factor that causes the deformation of the mill parts. Therefore, when using it, you must strictly follow the procedures to avoid overloading and local high temperatures to reduce the deformation of the parts;

The article mainly introduces the problem of how to reduce the deformation of the parts of the mill. The analysis of this problem is more detailed. It is mainly carried out from four aspects, namely, the design must be reasonable, the manufacturing must be meticulous, the warranty repair and reasonable use Multi-pronged approach in these areas can reduce the deformation of parts and ensure the smooth production.

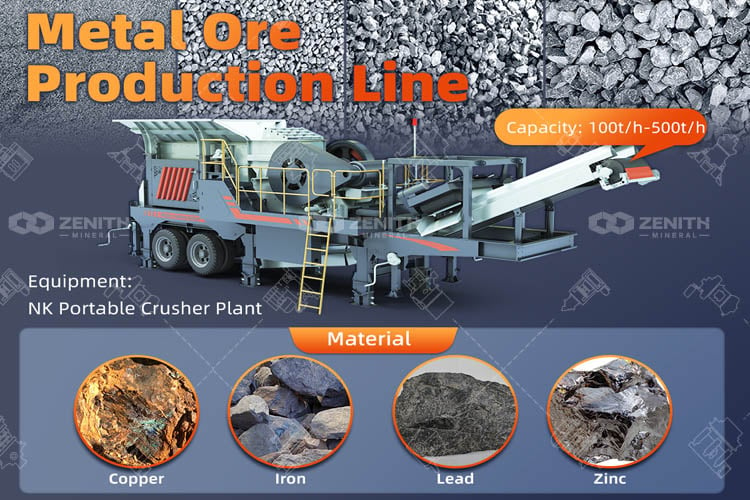

The NK Portable Crusher Plant is a powerful asset in the metal ore production line, offering a combination of high capacity, mobility, and advanced control systems.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

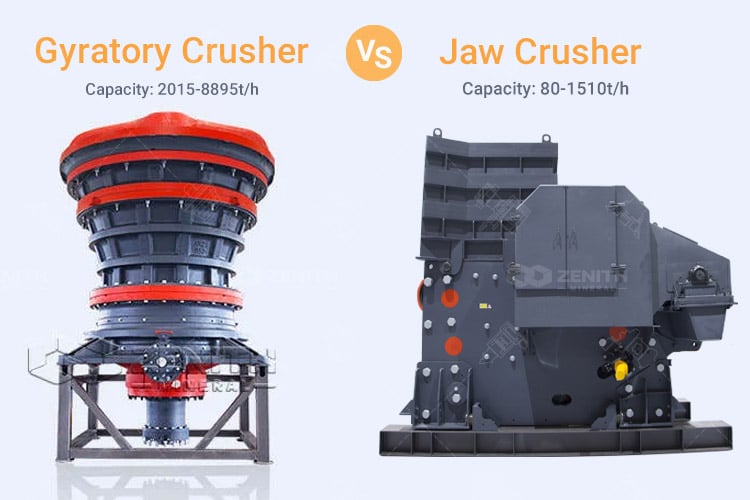

This article explores the key differences between gyratory crusher and jaw crusher, including their design, working principle, applications, capacity, maintenance and operating costs.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.