Raymond mill is popular because of its low price and large output. However, after running for a period of time, milling yield of Raymond mill may become lower, which will affect the benefit of the enterprise. How to solve these problems? Here are some methods to improve the yield and production efficiency of Raymond mill.

1. Reasonable selection of engine speed and improvement of grinding force

Because the grinding force mainly comes from the centrifugal force of the grinding roller, the rotation speed of the main engine directly affects the grinding force. The low speed of the driving shaft may be one of the reasons for the low powder production rate. Insufficient power, loose drive belt or serious wear will cause unstable speed reduction of the driving shaft.

Suggestion: increase the kinetic energy of the Raymond mill, adjust the belt or replace it.

2. Reasonably adjust the air pressure and air volume of the blower

Due to the different physical properties and chemical composition of various non-metallic minerals(such as graphite, gypsum and other minerals with low density), the air pressure and air volume should be adjusted properly, and smaller compared with the minerals with higher relative density (such as barite, iron ore, etc.). If it is too large, the coarse particles will not be well graded and then mixed into the finished products when passing through the classifier; if it is too small, it is easy to block the material in the main machine, so that the machine cannot run normally.

3. Reasonable design of blade device and high quality wear-resistant materials for grinding roller and ring

The blade is an important device to shovel the material directly between the grinding roller and the grinding ring. After technical development and improvement, the design of the blade of Raymond mill is reasonable, it can shovel up and make the material fully grind between the grinding roller and the grinding ring.

If Blade, grinding roller, grinding ring and other main wearing parts are seriously worn, the amount of powder production rate will be affected. Wear resistant parts should be high wear-resistant materials, such as high chromium cast iron. The blade can't shovel the material, the grinding roller ring is seriously worn which cannot play a good grinding effect, resulting in low powder processing rate, and the wearing parts should be replaced in time after wear.

4. Good lubrication for Raymond mill

The blunt grinding teeth will also affect the speed of Raymond mill. It is necessary to check the gear grinding and other transmission parts from time to time to prepare for lubrication and replacement.

5. Dredge the pipeline and seal it well

1) Due to the blockage of the conveying air duct of Raymond mill, the powder cannot be transported normally, which will lead to the problem of low powder output or even no powder discharge. To solve the problem, it is necessary to stop the machine to dredge the materials in the pipeline and restart the machine for blanking.

Suggestion: the superfine powder contained in the material has large coagulation effect, small loose specific gravity, large volume (the volume of 800 mesh product with the same weight is nearly twice as large as 325 mesh product), and it is easy to adhere to the pipe wall and silo wall, so it is not easy to fall down. Therefore, the inner wall of pipe and silo should be as smooth as possible, and the lining of galvanized sheet or stainless steel plate is better, and the unloading taper of silo should be as small as possible, it is better to add a wall vibrator.

2) Poor sealing of the pipeline will cause dust increase, negative pressure imbalance and low powder conveying rate. The pipeline sealing must be checked in place before production.

Suggestion: If the powder locking device at the discharge port of Raymond mill production line is not adjusted to the correct state, it will result in loose sealing and powder reverse suction. It is necessary to ensure that the powder locking device, return air pipe valve and other valves on the pipeline should be in good working condition.

6. Pay attention to the humidity, viscosity and hardness of materials

The performance of the Raymond mill is the main factor to determine the production efficiency, but the material properties, such as powder humidity, viscosity, hardness, discharge particle size requirements, etc., will also affect the powder yield. The best production effect can be achieved by running under the corresponding requirements in specifications and operating instructions of the Raymond mill.

Reasonable operation, good maintenance can maximize the life of Raymond mill, play the best performance, create the highest benefit. If you need more information about Raymond mill or other crushing or grinding equipment, please contact us.

Learn proven ways to reduce crushing plant operating costs, including equipment selection, energy efficiency, wear part control, and process optimization to lower cost per ton and improve ROI.

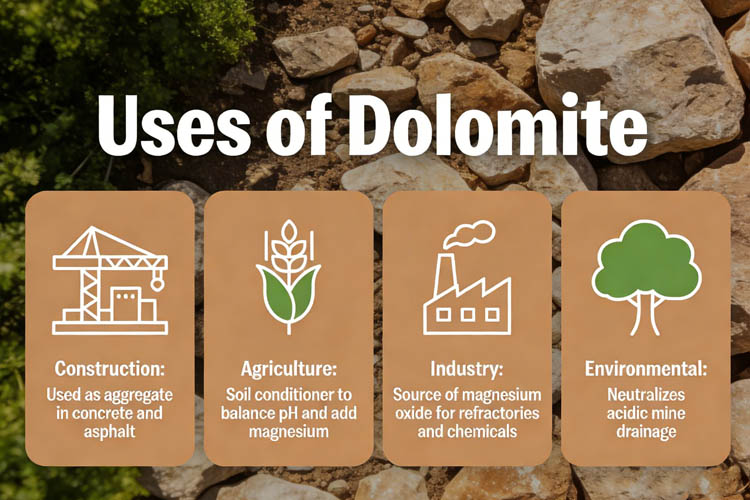

This article will explore 10 prominent uses of dolomite, shedding light on its versatility and highlighting its importance in today’s global economy.

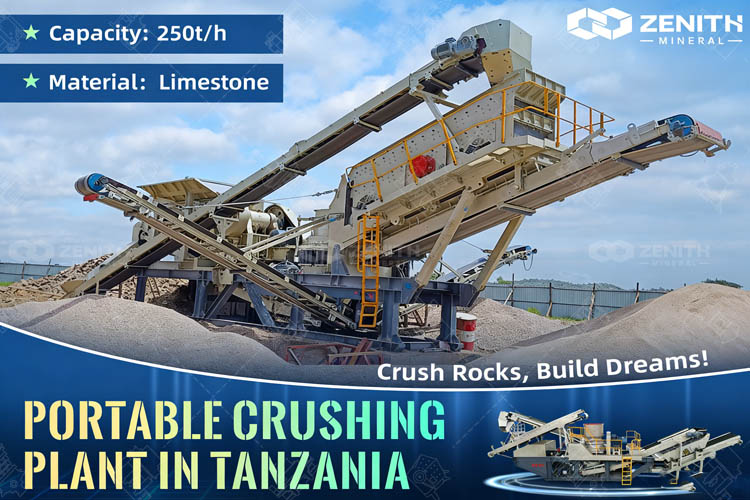

Discover the cost of portable crushing plants in Tanzania. Learn factors affecting price, capacity, mobility options, and how to choose the right solution for your mining or quarry project.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.