In the process of mineral processing, the operation of reducing the particle size to 20-5mm is called crushing, and the corresponding equipment is stone crusher. Commonly used stone crushing equipment are: jaw crusher, cone crusher, impact crusher, roller crusher, hammer crusher, etc.

Jaw crusher has the characteristics of simple structure, reliable work, easy manufacture and convenient maintenance. It is the most commonly used coarse crushing equipment in mineral processing.

The cone crusher can be divided into three types: coarse crushing, medium crushing and fine crushing according to its particle size range. It has the characteristics of large crushing ratio, uniform product size, high production efficiency, low energy consumption and easy adjustment of the discharge port.

The impact crusher has the characteristics of large crushing ratio, high crushing efficiency, low power consumption, less over crushing phenomenon, strong adaptability, small equipment volume, light weight, simple structure, easy manufacturing, convenient maintenance and so on. It is mainly used as medium and fine crushing equipment for various materials, and also as coarse crushing equipment.

The new type of sand making machine adopts modular structure design, which can be exchanged instantly. When processing materials, different crushing principles can be selected according to the properties of materials and the requirements of materials. There are two crushing forms of stone or stone iron, which can crush materials on demand.

Roller crusher can be divided into single roller, double roller, three roller and four roller according to the number of rollers. It has the characteristics of simple and compact structure, reliable operation, low cost, convenient adjustment of crushing particle size ratio and less over crushing particle size. Mainly used for medium and fine crushing of brittle and tough materials.

The composite crusher rotor adopts a new design structure, adopts the impact crusher steel disc structure and the hammer crusher's hammer disc staggered arrangement structure, and its structural design effectively enhances the crushing performance and improves the production efficiency of the equipment.

The material falls vertically from the upper part of the machine into the high-speed rotating impeller. Under the action of high-speed centrifugal force, it will shunt with another part in an umbrella form around the impeller to produce high-speed impact and crushing. After the materials collide with each other, they will be The material between the casings is crushed by multiple collisions and frictions formed by the eddy current between the materials, and is discharged directly from the lower part to form a closed circuit for multiple cycles. The screening equipment controls to reach the required finished product particle size.

Hammer crusher is similar to impact crusher in structure. It is mainly used for crushing medium hard and weak abrasive materials, such as limestone, coal, asbestos, cement clinker, metal slag, feed, etc.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

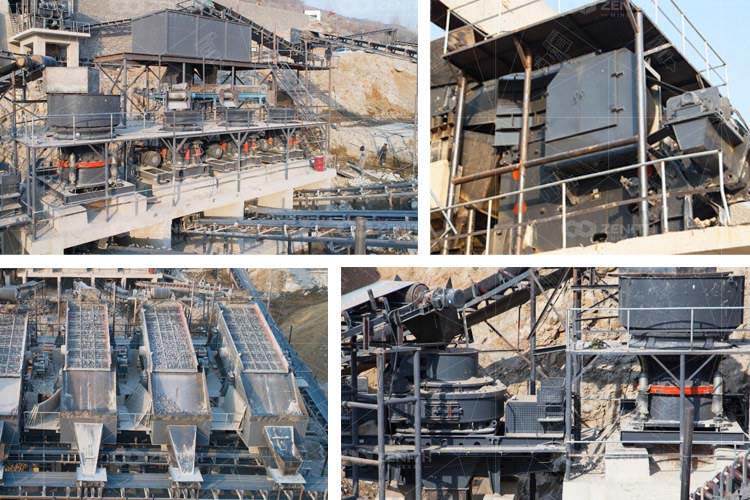

Stone crusher can be widely found in South Africa mining site, it is the basic machine for mineral processing line. Zenith will provide you with crushers of different styles and sizes at the best price according to your requirements.

Stone crusher for coarse crushing is an important driving force for the success of aggregate processing plant. Here are the tips to choose the most suitable coa

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.