Stone crusher for coarse crushing is an important driving force for the success of aggregate processing plant. Here are the tips to choose the most suitable coarse crusher.

Coarse crusher is the main equipment for crushing operation. After explosion, the materials are processed by coarse crusher and crushed into semi-finished materials with smaller granularity. And then after belt conveying, screening, medium crushing processing, final products are produced. The success of each component of the crushing station to output the final product depends on whether the coarse crusher can work properly, so it is very important to choose the right coarse crusher.

To choose proper coarse crusher, we should first confirm the purpose of the coarse stone crusher, which is very important.

To confirm the purpose of coarse crusher, these two factors should be considered: raw material size curve and rock types. Besides, we should also consider other factors, such as on-site long-term planning, discharge grading, raw material moisture content, required output capacity, etc.

Gyratory crusher is generally used in projects with an annual output of more than 10 million tons. This type of crusher generally needs to be customized, and it usually takes more than one year from purchase to delivery. In addition, on-site installation also takes one month. Therefore, this type of crusher is most suitable for projects with long-term plans. At the same time, it is also ideal crushing equipment for granite and other highly abrasive raw materials.

Jaw crusher is the most commonly used coarse crushing equipment. It can be used to crush highly abrasive raw materials. Compared with gyratory crusher, jaw crusher has higher mobility and can be moved to different mining platforms as required.

Impact crusher is most suitable for low abrasive materials such as limestone. The wear cost of this type of stone crusher will be relatively higher, but it can usually reduce the number of crushing sections and produce products with better shapes.

After determining the overall purpose of stone crusher, the next step is to test the expected performance of different crusher models at the installation site. At this time, a simulation test must be carried out.

The simulation test aims to determine the performance of the coarse crusher and evaluate the impact of the performance of coarse crusher on downstream equipment. Generally, we can select relevant software for simulation testing according to actual conditions (equipment type, site location, etc.).

After selecting proper stone crusher type and model, the last step is to install and start the coarse crusher on the project site.

According to different working sites, the installations of stone crusher are also different. In some cases, the installation process will become very complicated and difficult. To insure the correct installation of stone crusher, crusher manufacturers or distributors must arrange service technicians with professional knowledge to provide technical support for each installation step, which includes project management, system configuration, performance assessment and equipment-related training.

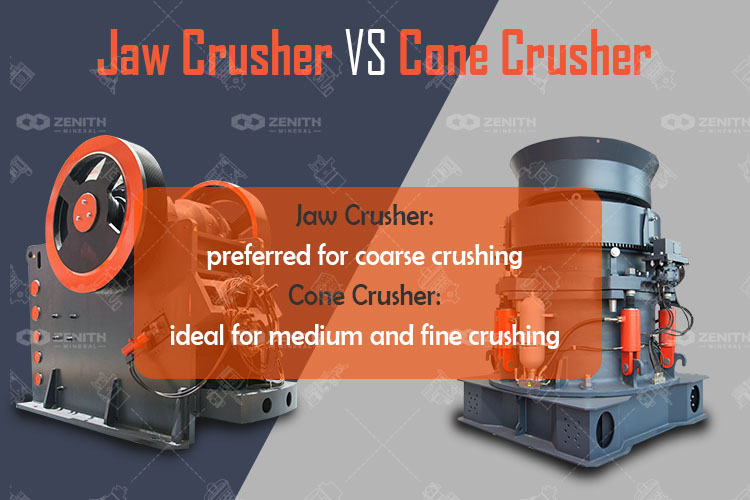

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

Stone crusher can be widely found in South Africa mining site, it is the basic machine for mineral processing line. Zenith will provide you with crushers of different styles and sizes at the best price according to your requirements.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.