As large-scale ore grinding equipment, the grinding mill inevitably fail during use due to its special role. Here are 17 frequent problems and solutions that may occur in the operation process of grinding mill.

Problem causes:

The V-belt is loose.

Solution:

By tightening the V-belt and adjusting other components appropriately, a satisfactory product particle size can be achieved.

Problem causes:

(1) The parts are not fastened;

(2) The bottom corner screw cap is loose;

(3) The main shaft is bent and deformed, and the weight of the parts is unbalanced.

Solution:

(1) Check the firmness of each component;

(2) Tighten the screw cap;

(3) Replace the main shaft and adjust the balance.

Problem causes:

(1) Excessive heating of the bearing;

(2) The bearing lacks oil or enters dust;

(3) The bearing is damaged.

Solution:

(1) Properly let the mill rest for a while;

(2) Check and clean the bearing and add oil to the bearing;

(3) Replace the new bearing in time to avoid damage to other components.

The rollers of the suspended shaft often do not rotate, and the current is as high as 250-160A (normal 180-200A).

Problem causes:

After disassembly, it was found that the sliding bearing of the suspension shaft was locked, and there was a large amount of oil mud in the suspension shaft cavity. The air outlet gap is too large, and the air pressure in the suspension shaft cavity is lower than the air pressure in the grinding chamber, so that dust enters the suspension shaft cavity.

Problem causes:

After stopping the machine, open the grinding chamber, and use the manual barring to find that some rollers rotate sometimes but do not rotate, and the rollers and grinding rings have disintegrated blocks. The problem is caused by poor lubrication of the roller bearing.

The surface of the roller is easy to be ground into a concave surface, and sometimes uneven stripes are found, and the grinding ring also has a concave surface.

Problem causes:

The connecting air pipe of the suspension oil chamber is worn out. It is caused by the continuous scouring of the powder in the grinding chamber.

Problem causes:

(1) The powder lock is not adjusted properly and the seal is not tight, causing powder to suck back;

(2) The blade is worn and the material cannot be shoveled;

(3) The air duct is blocked;

(4) The pipeline is leaking and the sealing is not good.

Solution:

(1) Check and adjust the seal of the powder lock;

(2) Replace the new blade;

(3) After cleaning the air duct material, unload it again;

(4) Seal the pipeline.

Problem causes:

(1) The blades of the analyzer are severely worn and cannot be classified;

(2) Inappropriate air volume of the fan.

Solution:

(1) Replace the blades;

(2) Appropriately turn down the fan inlet air volume to solve the problem of finished powder too thick, and if the finished powder is too thin, we should increase the inlet air volume.

Problem causes:

(1)The feeding amount is small, the blade is severely worn, and the material cannot be shoveled;

(2) The material has high hardness, the impact is large, or there is no material layer;

(3) The grinding roller and grinding ring are seriously deformed.

Solution:

(1) Adjust the feeding amount and replace the new blade;

(2) Change the feeding granularity;

(3) Replace the grinding rollers and grinding rings.

Problem causes:

(1) The feeding amount is excessive, and the air duct is blocked by the powder;

(2) The exhaust of the pipeline is not smooth, and the circulating airflow heats up, which increases the temperature of the machine and reduces the current of the fan.

Solution:

(1) Reduce the amount of feeding and remove the powder accumulated in the air duct;

(2) Open the large air duct valve, and control the temperature of the incoming material below 6 °C.

11. Fan vibration

Problem causes:

(1) Powder accumulation on the fan blades or unbalanced wear;

(2) The anchor bolts are loose.

Solution:

(1) Remove the powder accumulated on the blades or replace the blades;

(2) Tighten the anchor bolts.

Problem causes:

(1) The oil is cut off or the sealing ring is damaged;

(2) Lack of maintenance and cleaning for a long time.

Solution:

(1) Add oil in time according to the specified time;

(2) Regular cleaning and replacement of oil seals.

Problem causes:

The oil viscosity is large and the oil is thick, and the screw pump oil cannot be pumped up, so that the upper bearing is short of oil.

Solution:

(1) Check whether the grade and viscosity of the engine oil meet the requirements;

(2) Check the running direction of the analyzer.

Problem causes:

(1) The one-time feeding volume of grinding mill is too much, exceeding its working load, the energy consumption will increase, the required power will increase, and the current of the main unit will increase.

(2) If the initial temperature of the fed material is too high, it will also cause the current of the main unit increase.

Solution:

In the operation process of grinding mill, it is necessary to strictly control the feeding amount and the temperature of the feeding material, or it is also possible to reduce the workload of the main unit by increasing the size of the discharge port or opening the large air duct valve to reduce the workload of the main unit, so that the current of the main unit to keep within the normal range.

grinding roller assembly

Problem causes:

(1) The oil seal is damaged, causing the bearing to lack oil and enters dust.

(2) The screws of the gland and sealing cover at the upper end of the grinding roller assembly are loose.

(3) Fatigue damage is the most common way of bearing damage.

Problem causes:

The transmission mechanism runs unbalanced and loses its dynamic balance; the matching clearance between the grinding roller shaft and the bearing is too large.

Solution:

Readjust the transmission mechanism of the roller grinding mill to make it balanced; replace the severely worn bearings to restore the normal fit clearance.

Problem causes:

Low manufacturing precision, unbalanced dynamic balance of the grinding rollers; the centerlines of the two rollers are not in the same plane, resulting in vibration.

Solution:

After the grinding roller is machined, the dynamic balance should be checked, or the machining accuracy should be improved; when installing, make sure that the centerlines of the two axes are parallel.

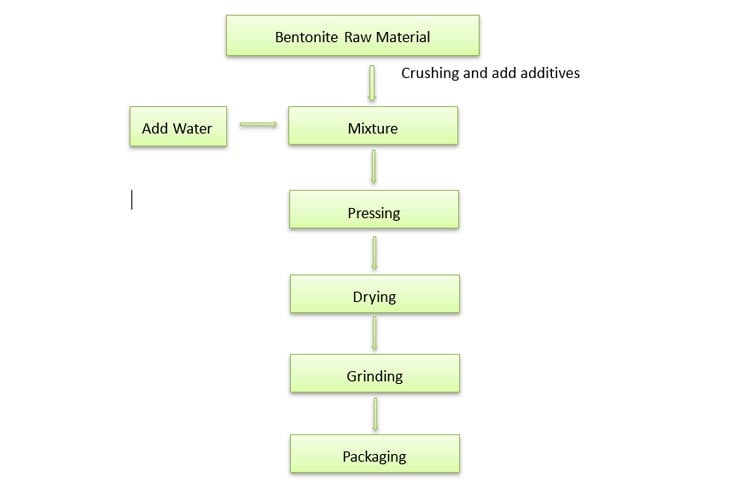

In bentonite processing plant, the production of bentonite mainly takes natural bentonite as raw material, and obtains corresponding products that meet the requirements by using purification, modification, activation, modification and other technologies. Here, purification and modification are mainly involved.

Introduction to Raymond MillRaymond mill, also known as Raymond grinding mill or Raymond roller mill, is a widely used grinding equipment for processing various

Although both of the two types belong to the grinding machine or mill, there are many differences in the operation, we should make a distinction and choose the right equipment according the situation of plant.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.