Cone crusher is widely used in mine production due to its high crushing efficiency, low maintenance cost and large output capacity. Cone crushers are divided into spring cone crushers and hydraulic cone crushers, both of which can be used for the production of medium and fine crushing of high-hardness materials.

In the following part, we mainly introduce how to properly maintain the hydraulic system of the hydraulic cone crusher.

To understand how to maintain the hydraulic system of the cone crusher, we must first have a clear understanding of the hydraulic system of hydraulic cone crusher. The hydraulic system on the cone crusher is mainly used to ensure the normal operation of the equipment and adjust the size of the discharge opening.

Single-cylinder hydraulic cone crusher

Multi-cylinder hydraulic cone crusher

Adjust the discharge opening: During normal operation, the hydraulic oil pump is used to inject or discharge oil into the main shaft cylinder, so that the main shaft moves up or down, the distance between mantle and concave is reduced or increased, and the size of the discharge opening is adjusted.

Iron passing and crushing cavity cleaning: When unbreakable foreign objects pass through the crushing cavity or the machine is overloaded for some reason, the hydraulic system realizes insurance, the hydraulic oil is injected into the accumulator, the main shaft falls, the discharge opening increases, and the foreign objects are discharged from the crushing cavity, the accumulator presses the oil back, and the crusher operates normally. If the foreign object is stuck in the ore discharge opening, the cavity cleaning system can be used to further enlarge the ore discharge opening, so that the foreign matter can be discharged from the crushing cavity. Under the action of the hydraulic system, the discharge opening is automatically reset, and the machine resumes normal work.

How do we need to properly maintain the hydraulic system of the cone crusher?

In the crushing process of ore, there will produce a lot of dust, to ensure the internal cleanliness of the cone crusher, we should pay attention to the removal of dust during use, and also prevent water from entering the hydraulic oil.

To ensure the cleanliness of the hydraulic system, it is recommended to use the same type of hydraulic oil for cleaning; otherwise, it may cause damage to the cone crusher.

Change hydraulic oil. It should be noted that a filter must be used when adding hydraulic oil and the filter must be kept clean. The amount of refueling should be appropriate, and the range of the specified oil level needs to be followed.

Pay attention to the replacement time of hydraulic oil. It is recommended to replace the hydraulic oil when the cone crusher is just shut down, while the hydraulic oil is still hot, which is conducive to draining the oil and sediment, and then injecting new hydraulic oil.

From the above maintenance items, we can see that the replacement of hydraulic oil plays a very important role in the maintenance of the hydraulic system of the cone crusher. So, how to judge whether the hydraulic oil should be replaced? There are mainly three aspects:

1. Degree of oxidation. Usually, the color of new hydraulic oil is relatively light, and there is no obvious odor, but with the extension of use time, long-term high-temperature oxidation can deepen the color of hydraulic oil. If the color of hydraulic oil of cone crusher is found to be dark brown, and accompanied by a smell, it means that the oil has been oxidized and needs to be replaced with new oil.

2. Water content. The water content of cone crusher hydraulic oil will affect its lubricating performance. When a large amount of water enters the hydraulic oil, because the water and oil do not mix, a turbid mixture will be formed during mixing. At this time, we need to replace the hydraulic oil to avoid affecting the performance of the cone crusher.

3. Impurity content. During the working process of the cone crusher, due to the continuous collision and the grinding between the various components, it is easy to generate debris, which will inevitably enter the hydraulic oil. If the hydraulic oil contains a lot of impurities, it will not only reduce the quality, but also damage the parts of the cone crusher. Therefore, after the hydraulic oil has been used for a period of time, we must pay attention to check the content of impurities in the hydraulic oil.

The above is the tip of the maintenance of the hydraulic system of the cone crusher. In the process of using the cone crusher, attention should be paid to the maintenance of the equipment to ensure the normal and efficient operation of the equipment.

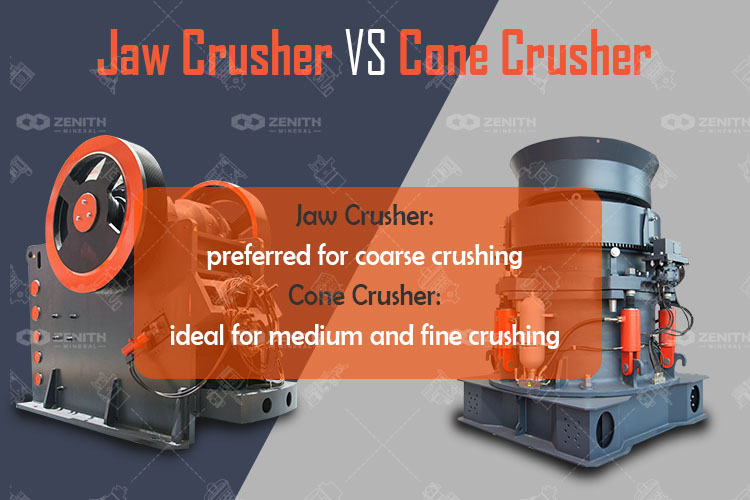

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

In Nigeria, Stone crushing is an important part in mining industry and require high quality stone crushing machines.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.