Gypsum is a hydrate with a chemical composition of calcium sulfate (CaSO4), and is a widely used industrial and building material.

Gypsum powder can be used in the construction industry. It is an environmentally friendly mineral powder, which is made by grinding mill.

Gypsum powder is one of the five major gel-type decorative materials. It is widely used in many industries and application fields such as construction, building materials, industrial molds and art models, chemical industry and agriculture, food processing and medical beauty. It is a very important The industrial raw materials are usually white and colorless, and sometimes they may become gray, light yellow, light brown and other different colors due to impurities.

Gypsum powder mainly has the following applications:

a: Anhydrite cement and cementitious materials: Anhydrite cement or cementitious materials can be produced by adding an appropriate amount of activator, suitable for the reinforcement of soft soil foundations, wall painting, mechanical models, tunnel support and production of fiber pressure boards .

b: Used as a co-solvent and scavenger in the glass production process.

c: Used as filler in industrial production of plastics, rubber, coatings, asphalt, linoleum, etc.

d: Cast-in-place piles and deep stirring piles are used as large expansion materials to increase frictional resistance.

a. used for the production of sulfuric acid, with the production of light cement.

b. used for the production of ammonium sulfate, with the production of light calcium carbonate.

a. Improve the soil, adjust the pH, suitable for soil improvement such as saline-alkali land and red soil.

b. used as calcium and sulfur compound mineral fertilizer in the cultivation of edible fungi to adjust the pH of the medium.

c. used as compound mineral feed additive in poultry and livestock feed.

The gypsum grinding process is mainly divided into four stages.

The first stage is crushing: The large pieces of gypsum material need to be crushed by the jaw crusher to the fineness that can enter the grinding mill.

The second stage is grinding: The crushed gypsum material is sent to the gypsum particle silo by the bucket elevator, and then evenly sent to the grinding chamber of the gypsum mill by the vibrating feeder for grinding process.

The third stage is classification: The pulverized materials are classified by the powder separator, and the unqualified powder is classified by the powder separator and then returned to the mill for re-grinding.

The fourth stage is calcination: The gypsum raw powder with the required fineness after grinding is sent to the boiling furnace for calcination by the powder separator, and the qualified gypsum powder after calcination is sent to the clinker silo for storage or sent to the product workshop for use.

In gypsum powder production process, grinding mill is the core equipment to produce gypsum powder. As a professional manufacturer, ZENITH provides different types of grinding mills for customers to choose.

After gypsum particles are evenly sent to the grinding chamber of Pendulum Roller Grinding Mill, they are blown away by airflow to the powder concentrator for classification. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector.

There are different series of pendulum roller mill, such as MRN series, MTM series and MTW series. The fineness of Pendulum Roller Grinding Mill can be adjusted between 1.6-0.045mm (fineness can reach to 0.038mm).

Vertical mill sets crushing, grinding, drying, classifying and transportation as a whole, the system is simple, the layout is compact and takes little space.

The fineness of gypsum powder can be adjusted between 80-400mesh. The hot air can adjust the temperature of different materials, and it can reach to the requirement of different humidity.

ZENITH XZM series ultrafine grinding mill is widely used for superfine powder production. The fineness of gypsum powder produced by ultrafine mill can reach to 2500mesh (5μm). It is suitable for grinding gypsum with moisture content below 6%.

And XZM series ultrafine grinding mill has the following advantages:

With the same fineness and power, the production capacity is 40% higher than that of jet grinding mill and stirred grinding mill;

The fineness can be adjusted between 325-2500 meshes, and the screening rate can achieve D97≤5μm once;

The lubricating device is installed outside of the main shaft, so that lubrication can be realized without shutdown;

Silencer and noise elimination room are configured to reduce noises.

Raymond mill has high processing capacity, high separation efficiency and low energy consumption. More importantly, Raymond mill forms a complete closed-circuit circulation system with other auxiliary devices together. The system runs under negative pressure. It is more environmentally friendly.

Raymond mill can be used for producing gypsum powder with fineness 1.6-0.045mm (325mesh), and the output capacity can reach to 11 tons per hour.

Besides gypsum, the above mentioned gypsum powder making machine can also be used to process many other materials, such as limestone, barite, talc, feldspar, fluorite, calcite, dolomite, bentonite and so on. If you are interested in gypsum powder making machine, feel free to contact us!

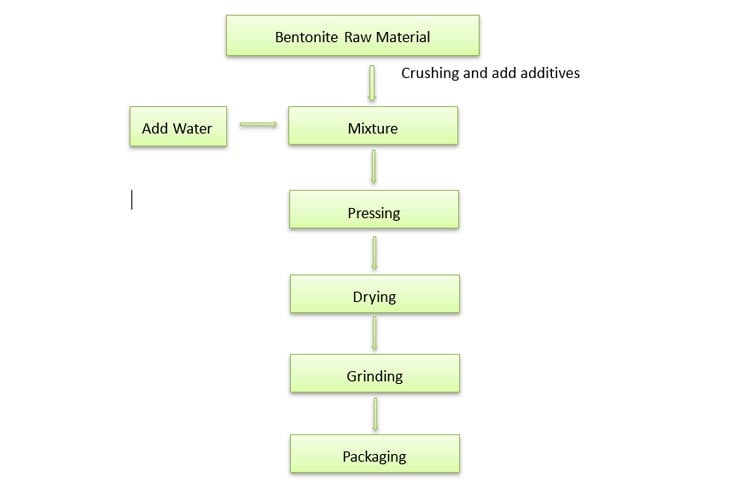

In bentonite processing plant, the production of bentonite mainly takes natural bentonite as raw material, and obtains corresponding products that meet the requirements by using purification, modification, activation, modification and other technologies. Here, purification and modification are mainly involved.

Powdered gypsum can be used in construction industry, building materials industry, chemical industry, medicine and medical treatment industry, light industry, etc.

dolomite processing plant can be divided into dolomite crushing and sand making plant and dolomite grinding plant.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.