Jaw crushers are a workhorse in the mining industry, responsible for the crucial first stage of size reduction. Understanding the technical specifications of jaw crusher is essential for selecting the right crusher that meets your operational needs. This comprehensive technical guide covers the key details you need to know when evaluating jaw crusher models for your mining application.

Manufacturer Name and Model: The technical sheet will identify the crusher manufacturer and the specific model within their product lineup. This information is crucial for understanding the design features and capabilities of the equipment.

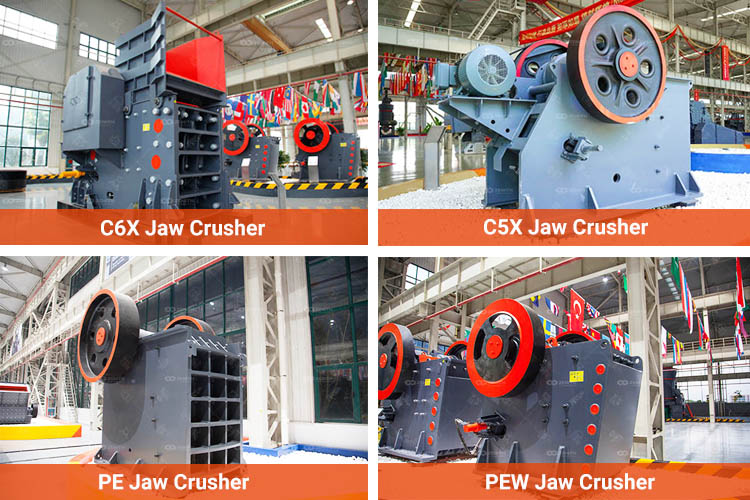

Jaw crusher come in various configurations, but the most common types are:

By thoroughly understanding the technical specifications outlined in this guide, you can confidently select the ideal jaw crusher that will optimize your mining operations and maximize productivity.

When selecting the right jaw crusher for your mining operation, it's crucial to closely examine the technical specifications and match them to your specific needs. This comparison process allows you to identify the model that will deliver the optimal performance and efficiency for your application.

When evaluating jaw crusher models, it's important to prioritize performance over strict efficiency considerations. A larger, higher-capacity crusher will generally require a more powerful motor, leading to higher energy consumption. However, this trade-off can be worthwhile if the increased production capacity aligns with your operational needs.

Analyze your budget, power constraints, and overall requirements to strike the right balance between crusher performance and energy efficiency. By carefully matching the technical specifications to your unique mining application, you can identify the jaw crusher that will deliver optimal productivity and cost-effectiveness.

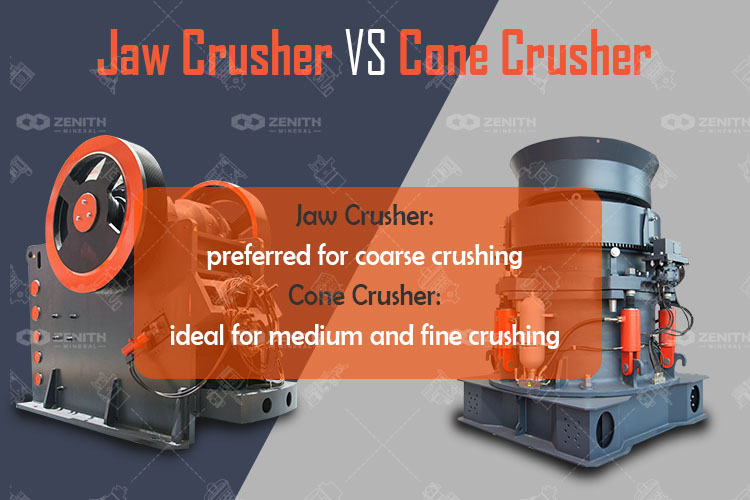

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

ZENITH's 5 types of jaw crushers have reliable quality and outstanding safety performance, and is widely recognized by users around the world.

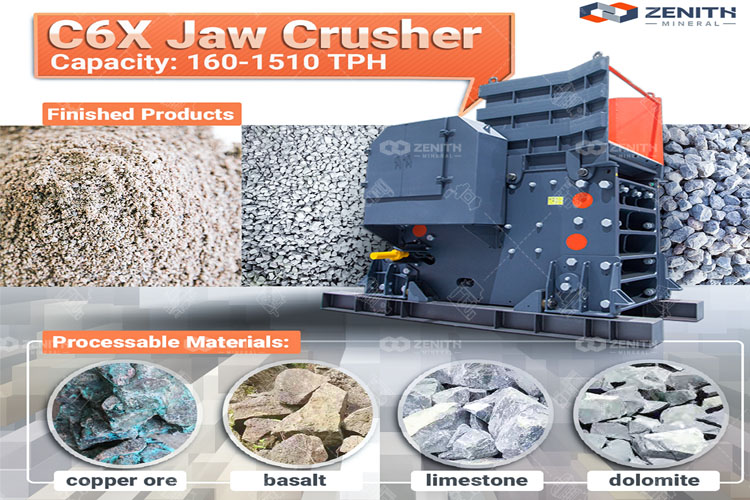

A jaw crusher is a type of primary crusher used in mines and ore processing plants. It reduces large aggregates to smaller aggregate. Jaw crushers are an excellent choice for primary crushing in a wide variety of applications.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.