Jaw crusher is one of the most commonly used crushing equipment in industrial processes today. As primary crushers, jaw crusher is designed to break bulky materials into smaller sizes at the initial stage of size reduction. They utilize compressive force for material crushing, employing moving jaw plates that simulate a jaw crushing action similar to that of an animal.

A typical jaw crusher consists of a fixed jaw plate and a swing jaw mounted on an eccentric shaft. As material enters the crushing chamber, the swing jaw crushes and fractures it against the fixed jaw. The reduction process continues as the swinging motion further presses and squeezes the feed between the jaws until it is small enough to pass through the discharge opening.

Jaw crushers provide reliable and robust crushing performance for mineral processing, aggregate production, and various industrial sectors that require rock size reduction. Capable of handling diverse feed materials from soft to extreme hard abrasive types, they are engineered for sizes between 25mm to 1200mm and production capacities ranging from 15 t/h to 1500 t/h. Both stationary and mobile configurations are available.

Some key factors that determine suitable jaw crusher models are the required reduction ratio, feed material characteristics, production capacity, and equipment portability. As primary crushing units, jaw crushers must be able to withstand high stresses whilst achieving quality outputs for further downstream processes. Their simple yet rugged designs also facilitate low-cost installation and maintenance.

The jaw crusher has reliable quality and outstanding safety performance, and is widely recognized by users around the world. Help customers carry out efficient production in mining, construction, infrastructure and other industries, and achieve resource conservation and environmental protection.

Zenith jaw crushers have achieved strong sales penetration across international markets. Applications in over 100 countries such as Zimbabwe, South Africa, Kenya, Philippines, Nigeria, Ethiopia, Ghana, UK, Malaysia, Canada and so on showcase their field-proven performance under diverse operating conditions.

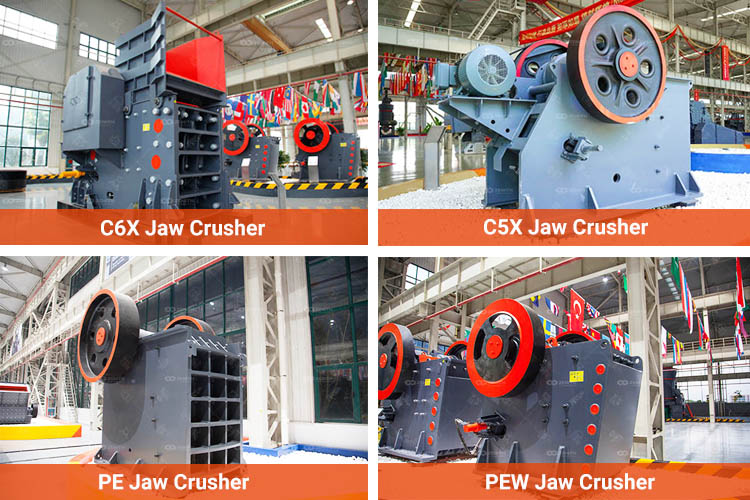

As a leading manufacturer, Zenith has developed diverse jaw crusher models to suit varied primary crushing requirements. This article examines Zenith's PE, PEW, C6X, C5X series jaw crusher and mobile jaw crusher, analyzing designs, specifications, applications and innovation within each type.

Applying next-generation kinematic design, C6X jaw crusher offers advanced crushing efficiency and performance. High-endurance cast manganese jaw plates resist impact and abrasion. Larger moving jaw stocks accommodate larger feed sizes with balanced stress distribution. Vibrating feeders optimize material bed formation and throughput. C6X jaw deliver up to 1500 tons/hour primary crushing capacity even at maximum densities and feed rates. They reduce operating costs through energy savings and minimal downtime.

The advanced C5X jaw crusher features a robust design developed for mining and heavy duty aggregates applications. An enlarged receiving chamber accept coarse feed sizes up to 1.2mx2.5m. Mined ores producing consistent fines experience few blockages. Re-engineered steel frame and main shaft bearings further strengthen C5X jaw crusher's robustness under substantial loads. Patented cavity profiles shape cubical rock with high reduction ratios. V-Groove Rubber Bellows feeders deliver steady material flow.

The PE series comprises versatile, simplified jaw crusher for medium-capacity primary crushing duties. Models include the PE150×250, PE250×400 and larger PE500×750. Applying a rotary eccentric shaft movement, material is compressed between a fixed and swing jaw. This generates even crushing flow and high reduction ratios. Suitable for crushing limestone, coal and various minerals, PE units deliver capacities up to 500 tons/hour. Quality castings and lubrication systems facilitate low-maintenance operation.

Designed for higher throughput needs, PEW jaw crusher adopts a welded, rectangular structure for increased strength. Wider cavity depth and optimized kinematic enhancing input energy transfer. The PEW760 and PEW860 models provide up to 500 tons/hour of high-quality aggregate production even in handling hard granite and basalt. Hydraulic safety guards allow residue clearing without opening the crushing chamber. PEW units have proven indispensable across mining and infrastructure projects worldwide.

Incorporating the crushing force of Zenith's stationary jaw crushers, their mobile series are widely used in construction, infrastructure projects and remote mining operations.

Robust understructures with ample ground clearance allow stable operation even on uneven terrain. Vibration isolated designs minimize noise levels for environmental compliance. Remote control station enhances operator safety by separating them from moving elements.

Mobile crushers easily follow excavation work across open pits and quarry faces. Their compact dimensions facilitate transport between job sites. Automatic lubrication systems and quick assembly features accelerate commissioning and changeovers.

On-board generators supply steady power to crushers, feeders and conveyors. Large capacity diesel tanks enable long operational cycles before refueling is needed. Mobile plants deliver premiere flexibility and performance to mining, infrastructure and recycling applications globally.

Zenith's research produces premium wear parts for prolonged machine lifetimes. Features include:

Original spare components matching original designs ensure crushers maintain premium factory-backed performance reliably.

Zenith's comprehensive jaw crusher selection addresses diverse primary crushing missions. From mining to infrastructure, their expertise and dedication to innovation provides a complete solution optimizing throughput, safety and low costs. Quality systems deliver field-proven, highly productive crushing worldwide with minimized environmental impacts.

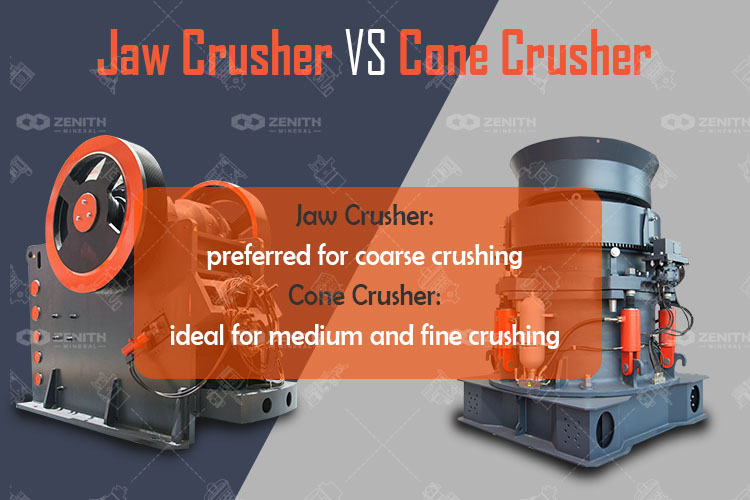

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

We have different types of jaw crusher for sale Philippines, such as PE series jaw crusher, PEW series jaw crusher, C6X series jaw crusher and mobile jaw crusher etc.

In South Africa, Jaw crusher in south africa has wide applications in mining, metallurgy, construction, road, railway, water conservancy, chemical and many other industries.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.