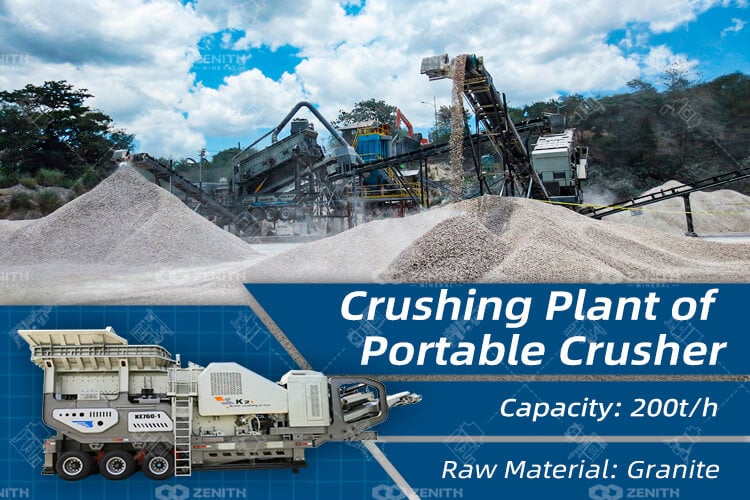

Portable rock crushers are mobile crushing and screening plants that are designed to be easily transported between different work sites. They are typically compact in size and can be towed or transported on a trailer. Portable rock crusher is equipped with a crusher unit, a vibrating feeder, and a conveyor, allowing for on-site crushing of rocks and materials. They provide the advantage of mobility, allowing operators to bring the crushing process directly to the location where the materials are generated or needed. Portable rock crushers are commonly used in construction, mining, and recycling applications.

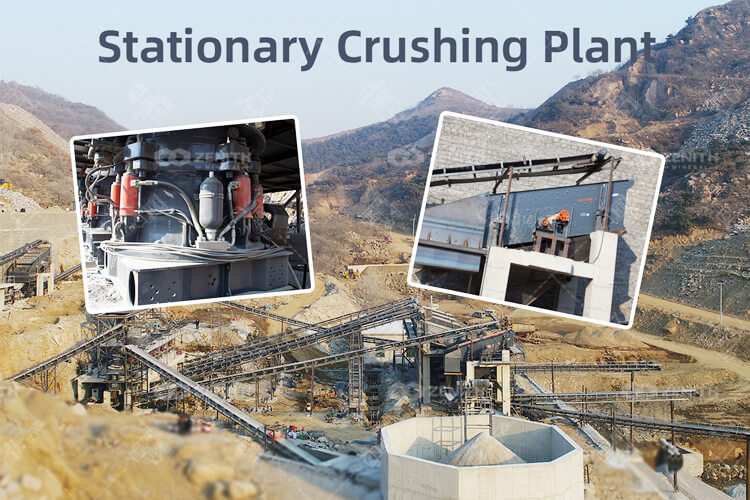

Stationary crusher, as the name suggests, are fixed crushing and screening plants that remain in a permanent location. They are designed to handle large volumes of material over an extended period. Stationary crushers are typically larger and more robust than portable crushers, and they require infrastructure such as foundations and conveyors. They are suitable for long-term operations and can handle high-capacity crushing needs. Stationary crushers are commonly used in mining, quarrying, and aggregate production industries.

When comparing portable rock crushers to stationary crushers, there are several factors to consider, including mobility, flexibility, efficiency, and cost. Here's a breakdown of the key differences:

1. Mobility

2. Flexibility

3. Efficiency

4. Cost

It's important to note that the choice between portable rock crushers and stationary crushers depends on the specific needs and circumstances of each project. Factors such as the nature of the materials, required output size, project duration, and budget will all play a role in determining the most suitable option.

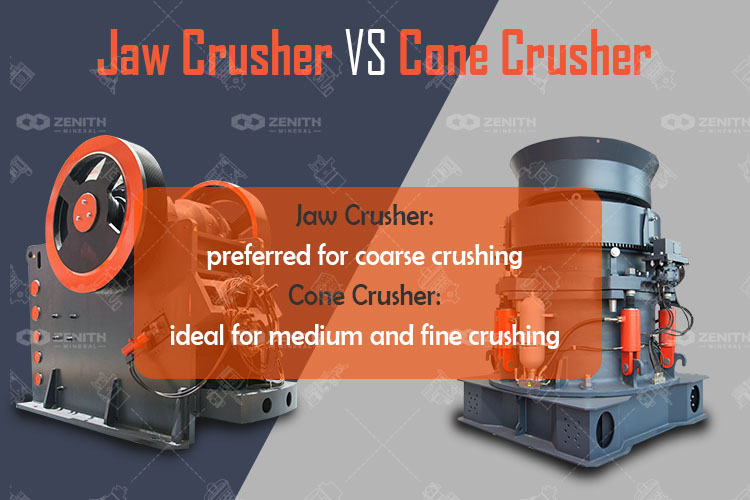

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

Crushing and screening equipment is the key to the recycling of construction waste. For construction waste treatment, ZENITH recommends mobile crusher.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.