River stone, known for their smooth texture and durability, are widely used in construction, landscaping, and infrastructure projects. However, processing these stones into usable materials requires specialized equipment and expertise. A well-designed river stone crushing plant is essential to maximize efficiency, reduce costs, and produce high-quality aggregates.

A river stone crushing plant is a facility designed to process river stones into various sizes of aggregates, such as sand, gravel, and crushed stone. These materials are used in construction projects, road building, and concrete production. The plant typically includes crushing, screening, and washing equipment to ensure the final products meet industry standards.

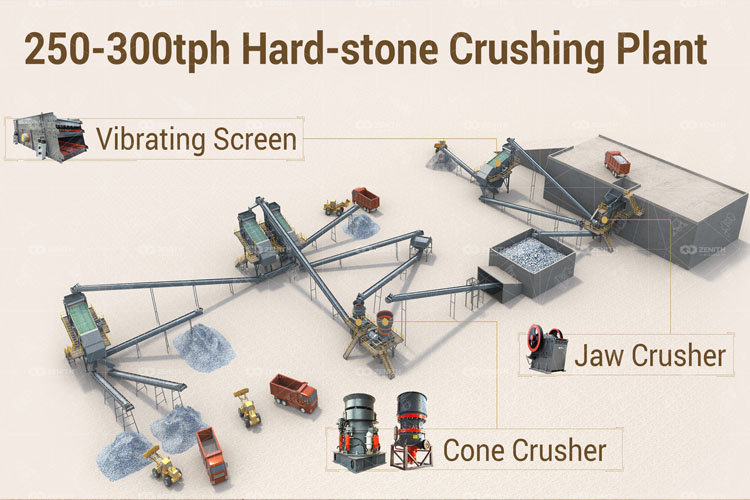

A river stone crushing plant is a complex system that consists of several components, each playing a specific role in ensuring the efficient processing of materials. The key components of a river stone crushing plant include:

The feeding system is responsible for directing the raw river stones into the crushing equipment. It can include a variety of components, such as hoppers, vibrating feeders, and belt conveyors. The role of this system is crucial, as it controls the flow of materials to the crusher.

The core of any crushing plant is the crushing equipment, which breaks down the large river stones into smaller, more manageable sizes. Common types of crushers used in river stone processing include:

Jaw Crusher: Typically used for primary crushing, jaw crushers apply compressive force to break large river stones into smaller pieces. These crushers are known for their ability to handle large feed sizes and produce a coarse output.

Cone Crusher: Used for secondary or tertiary crushing, cone crushers provide a finer output and better shape. These crushers work by applying compressive force between a rotating mantle and a stationary bowl liner.

Impact Crusher: Impact crushers use high-speed rotors to strike river stones, breaking them into smaller fragments. They are ideal for producing high-quality aggregates with a cubical shape.

After the crushing process, the material needs to be screened to separate the different sizes of aggregates. Screening equipment, such as vibrating screens or trommels, plays a crucial role in separating the finer particles from the larger ones. This ensures that the crushed material meets the desired specifications for different applications.

Sometimes, the river stone aggregates contain impurities such as clay, dust, and sand. A washing system, typically consisting of a scrubber or a hydrocyclone, helps remove these impurities, ensuring that the final products are of high quality. Washing also improves the appearance of the aggregates, making them more suitable for use in decorative landscaping projects.

The crushed and screened aggregates are then transported through a series of conveyors to storage areas or to the next stage of processing. Conveyor belts are designed to handle different types of material, ensuring a smooth and efficient transfer of products.

Modern river stone crushing plants are equipped with automated control systems to monitor and optimize plant performance. These systems help regulate the feed rate, crusher settings, and screening processes, ensuring consistent output and reducing the risk of equipment failure.

The process of crushing river stones involves several stages, each crucial for ensuring the final product meets industry standards.

The first step in the process is the extraction of river stone from riverbeds or quarries. This step is typically performed using excavators or draglines to collect large stones that will later be processed in the crushing plant.

Once the stones are extracted, they are loaded into a feeding system, which directs them to the primary crusher. This step is crucial for ensuring that the material is evenly distributed and fed into the system at a consistent rate.

The primary crushing stage usually involves a jaw crusher, which breaks down the large stones into smaller fragments. The output from the primary crusher is typically larger than the desired final product, which is why secondary or tertiary crushers are often used to further reduce the size.

At this stage, the material is fed into cone crushers or impact crushers for further reduction. These crushers provide a finer, more uniform product that is more suitable for various construction applications.

After the material has been crushed, it is passed through a screening system. This system sorts the material into different sizes, ensuring that the final product is of consistent quality and can be used in various applications.

If necessary, the aggregates are washed to remove dust, clay, and other impurities. This ensures that the final product is clean, which is particularly important for applications such as concrete production and decorative landscaping.

Finally, the processed river stone is stored in silos or stockpiles until it is ready for distribution. From here, it is transported to construction sites or other areas where it is needed.

Investing in a river stone crushing plant can provide numerous benefits for companies involved in construction, landscaping, and other industries that require aggregates:

Crushed river stone has a wide range of applications, including:

A well-designed river stone crushing plant is essential for producing high-quality aggregates efficiently and cost-effectively. By leveraging advanced technology and customized solutions, ZENITH helps clients optimize their operations and achieve their goals. Whether you’re working on a small construction project or a large-scale infrastructure development, ZENITH’s expertise and equipment can make all the difference.

This article will explore three main types of stone crushing plants: the traditional combination of jaw crusher, impact crusher, cone crusher, and vibrating screen; the innovative VU tower-like system; and the versatile portable crushing plant.

The price of stone crusher machines can vary significantly between countries due to factors like local manufacturing, taxes, transportation costs and currency fluctuations.

River pebble is a kind of very important material that can be used in construction industry. And after a series of crushing, screening, sand making process

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.