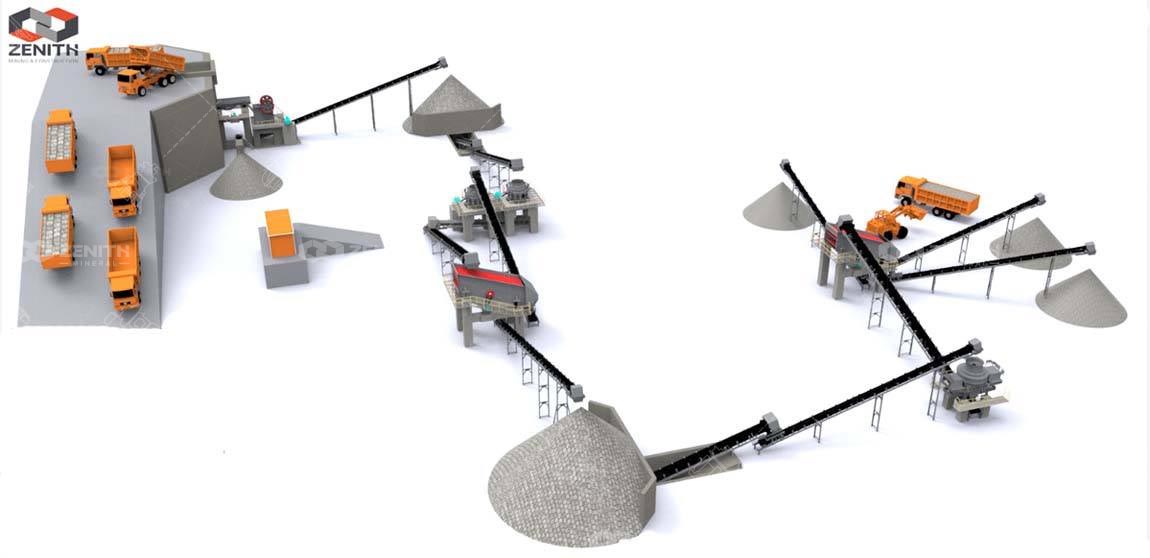

In the following part, we take one mechanical sand and gravel aggregate project as an example, and focus on the process design and equipment configuration plan of the dry-process high-quality mechanical sand and gravel aggregate production line.

A certain mechanism sand and gravel aggregate project, the ore raw material is dolomitic limestone, the average compressive strength is 94MPa, the design capacity is 400t/h, the front of the production line adopts jaw crusher + desilting screening + pre-screening + cone crusher + vertical shaft impact crusher for shaping+ finished product screening, the back of the production line adopts tower-like sand making process.

In aggregate production, impact crusher, hammer crusher, jaw crusher and gyratory crusher are the commonly used primary crushing equipment.

Impact crusher

Impact crusher is mainly used to process raw materials with medium or low hardness. It crushes raw materials through impacting force produced by high speed rotated blow bar. ZENITH provides 3 different series of impact crusher for customers to choose, which are PF series impact crusher, PFW series impact crusher and CI5X series impact crusher.

Jaw crusher

Jaw crusher has wide applications in mining, metallurgy, construction, road, railway, water conservancy, chemical and many other industries. It can be used for crushing various kinds of raw materials with compression strength below 320Mpa and it is first choice for primary crushing.

Gyratory Crusher

ZENITH HGT Series Gyratory Crusher was developed to cater for market demands for large crushing equipment. It combines the industrial developmental needs with internationally advanced crushing technologies. It integrates mechanical, hydraulic, electric, automation and intelligent controlling technologies. Compared with traditional gyratory crushers, it has higher crushing efficiency, lower production costs and more convenient maintenance.

There are two main types of feeding equipment for coarse crushing: bar feeder and heavy plate feeder.

In the process flow of the case, a flap switch valve is set under the screen bar of the bar feeder. When the mud content of the raw material is very low, the material under the screen bar can be directly fed into the subsequent production system without entering the desilting screening.

The intermediate stockpile after coarse crushing can be divided into two sections with different operating rates. When the equipment in the front section cannot operate normally due to mine supply, road transportation, equipment maintenance, etc., the equipment in the latter section can continue to produce by relying on the material stored in the intermediate stockpile.

Through pre-screening, the materials smaller than the particles discharged from the medium crushing equipment are screened out in advance without entering the medium crushing equipment, so as to avoid excessive crushing. It is also possible to control the amount of material fed into the medium and fine crushing or shaping equipment and the maximum feeding particle size through the pre-screened screen size. After optimized configuration, the selection specifications of the crushing equipment can be reduced or the number of equipment can be reduced.

In the process flow of the project, the medium crushing cone crusher and the pre-screen constitute a closed-circuit system, so the pre-screen is also used for check screening. The material under the screen less than 12mm can be directly used as the raw material of the machine-made sand without entering the crushing system, which can avoid excessive crushing, and is also beneficial to release the output of the crushing system, and the 12-50mm material enters the shaping equipment.

The third section of crushing adopts vertical shaft impact crusher, which has the dual function of crushing and shaping. The feeding materials come from the check screening in advance, and the material is crushed and shaped by vertical shaft impact crusher and then fed into the finished screen. The finished screen and vertical shaft impact crusher constitute a closed circuit system.

In the process flow of the project case, a flap valve is configured at the hopper of the finished product screening, which can return part of the finished aggregate to the vertical shaft impact crusher for re-crushing, so as to adjust the output ratio of the final product and make the system regulation more flexible.

It is not necessary to set a buffer bin before the screening equipment, but it is necessary to set a buffer bin before the crushing equipment, which is convenient for the loader or dump truck to unload.

Tower-like sand making system has significant advantages in terms of environmental protection, land occupation and energy efficiency. There are two problems that need to be solved in the production of tower-like sand making system:

One is grading and powder classification, and the materials smaller than 2.36mm in the crushed products (2.36mm is an approximate size, the same below) are screened out and sorted and processed at the same time. If the classification and screening of this part of the material cannot be well solved, the production capacity will be reduced and the control of the fineness modulus will be affected;

The second is the re-crushing and the control of materials >4.75mm and some 2.36-4.75mm materials will return to the vertical shaft impact crusher for re-crushing, which is a core link of grading adjustment.

The quality of the finished sand produced by VU tower-like sand making system meets the national standards. During operation, there is no sludge, no wastewater and no dust in the production process, which fully meets the national environmental protection requirements and brings huge benefits and development opportunities to the aggregate field and other industries.

After VU sand-making and reshaping, raw materials below 15mm are divided into 3 ways under the action of mold control screen and dust removal module: stone powder, return material and quasi- finished sand. The stone powder is uniformly stored in the powder ore bin after passing through the dust removal module, and the quasi-finished sand enters the grain-optimized machine for further shaping. The whole processing will be completed after humidification and stirring.

The industrialized mechanism sand and gravel aggregate production line should avoid large-scale and low-level repetitive construction. The high-quality machine-made sand and gravel aggregate production line with moderate scale, excellent products, emphasis on process control, high degree of automation, energy saving and environmental protection will become the development trend of aggregate project construction in the future.

The good development prospects and huge market space of the industry have attracted capital from all walks of life, and the modernization and intelligent development of the sand and gravel industry has become a trend.

Aggregate is the basic material of engineering construction, which is widely used in electricity, construction, roads, highways and other construction fields.

With the construction of high-speed railways, highways, nuclear power plants, and super high-rise buildings, ordinary sand and gravel aggregates can no longer meet the raw material needs of high-performance concrete.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.