Silica sand is a kind of silicate mineral that has high hardness, good wear-resistance and stable chemical properties. Its main mineral component is SiO2, and its chemical, thermal, and mechanical properties have obvious anisotropy. Silica sand has high fire resistance.

According to different mining and processing methods, silica sand can be divided into artificial silica sand and natural silica sand such as washed silica sand, scrubbed silica sand and extracted (flotation) sand etc.

Silica sand is an important industrial mineral raw material, widely used in glass, casting, ceramics and refractory materials, metallurgy, construction, chemical, plastics, rubber, abrasives and other industries.

Common specifications of silica sand are: 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20mesh, 20-40mesh, 40-80mesh, 100-120mesh, 200mesh, 325mesh.

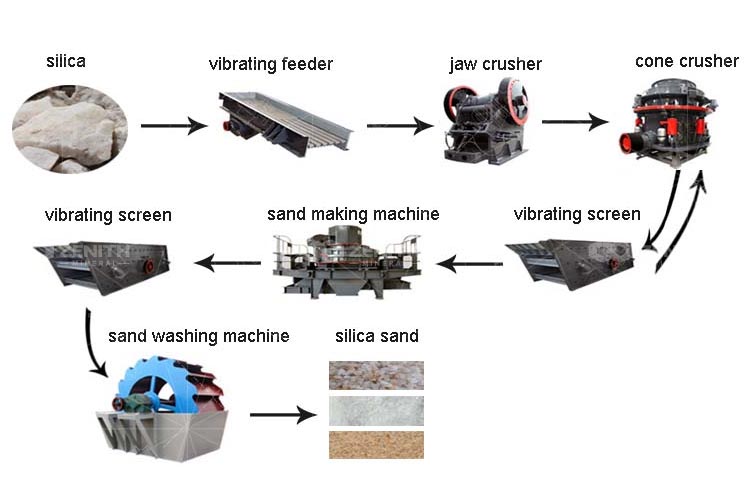

To get silica sand, we need crushing and grinding process if the raw material is large. ZENITH can supply complete production plant using its own equipment. And the experts can assist you choose the suitable equipment and design the silica sand processing plant to meet all your production goals.

In silica sand production plant, silica sand grinding machine is the key equipment. ZENITH offers the following grinding machines for this process stage:

Capacity: 3-45t/h

Max. Input Size: 50mm

Output Size: 80-425mesh

MTW trapezium grinding mill owns many independent patents and it is one of the most popular silica sand grinding machines of ZENITH. And here are the main reasons why it is popular among customers:

MTW silica sand grinding mill has more compact structure, occupying smaller floor area. So the investment of foundation and factory construction is less, saving money for customers.

MTW grinding mill is equipped with a professional dust remover, effectively reduce the dust in the surrounding environment, and guarantee the safety of operators.

The service life of grinding rollers and rings are 1.7-2.5 times longs than that of traditional silica grinding mills. This will also reduce the production cost.

In addition, the special design and the thin oil lubrication system are also the reasons that customers prefer to choose MTW silica sand grinding mill.

Capacity: 10-170t/h

Max. Input Size: 50mm

Min. Output Size: 600mesh

LM vertical roller mill combines crushing, grinding, powder selection, drying and material conveying into one set. Therefore, it only needs small floor area. The occupational area is about 50% of that of ball mill system, which saves a lot of money on the foundation construction.

The whole system of LM vertical roller mill is sealed and works under negative pressure, so there is no dust escaped and the working environment is clean.

Materials stay in the mill for a short time, which can effectively avoid over-grinding and is easy to control& adjust the fineness of final silica sand.

Vertical roller mill can handle materials with different moisture content, because hot air can be inlet into the system to dry the material until the moisture content is proper. There is no need to equip extra drying equipment.

Ball mill is the most widely used kind of grinding equipment, especially for silica grinding in beneficiation plant. ZENITH ball mill can carry out dry or wet pulverizing and can meet demand for sustainable large-scale production. The most widely used in the production of silica sand are wet overflow ball mill and grate ball mill.

The grinding process of ball mill is mainly completely by the impact and grinding of the steel balls on the silica sand.

ZENITH ball mill features:

Eco-friendly production

Longer service life

Automatic control

Higher Productivity yet Less Energy Consumption

Capacity: 3-22t/h

Max. Input Size: 35mm

MTM series silica grinding machine adopts world-leading powder processing technology. Compared with traditional mills like Raymond mill, ball mill and high-pressure hanging roller mill, it has many advantages.

The structure is updated

The spring connection structure is updated, which not only reduce shock of large particles on the axis and bearing, but also improve the crushing strength of the grinding rollers.

Energy-saving

The power consumption of MTM medium-speed grinding mill is over 60% lower than that of ball mill of the same level. And the working efficiency of the fan can reach 85%, which will also improve the working efficiency of the mill and reduce energy consumption.

Easy discharging

The inlet of the air duct is smoother because the resistance is little and the outlet is easy for discharging of materials.

MRN series pendulum roller grinding mill represents the advanced grinding technology at present. It is suitable for processing non-inflammable and non-explosive mineral materials with Mohs’ hardness below 9 and humidity lower than 6%.

Therefore, MRN series grinding mill is one of the suitable equipment for silica sand grinding.

Capacity: 7-45t/h

Max. Input Size: 50mm

Min. Output Size: 1.6-0.045mm

This type of silica sand grinding mill adopts thin oil lubrication, making the grinding mill easy to maintain and operate. And the fineness of silica sand can be adjusted according to production goals, meeting various needs with one machine, thus reduce the investment cost.

In addition to the above mentioned series of silica sand grinding machines, there are other grinding machines that can be used for silica sand grinding, such as Raymond mill, XZM grinding mill and so on.

Generally, when selecting silica sand grinding machines, enterprises must comprehensively consider factors such as abrasive requirements, production environment, energy consumption, and material properties to ultimately select the most suitable one for their usage requirements.

If you do not know how to choose suitable silica sand grinding machine, do not worry, contact ZENITH! The experts will recommend one for you according to the production requirements.

If you want to know about the profit, you must first understand the cost composition in the silica sand washing plant.

From the perspective of development process, silica sand is widely used in glass, casting, ceramics and refractory materials, metallurgy, construction, chemical industry, plastics, rubber, abrasives and other industries.

With the construction of high-speed railways, highways, nuclear power plants, and super high-rise buildings, ordinary sand and gravel aggregates can no longer meet the raw material needs of high-performance concrete.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.