Stone crushers play a crucial role in the mining industry of Zimbabwe. They are essential equipment for breaking down large stones into smaller pieces, which are used for various purposes such as construction, road building, and manufacturing of concrete and asphalt. This article explores the significant role that stone crushers play in Zimbabwe's mining sector and their impact on the overall industry.

Zimbabwe's mining industry relies on various types of quarry crushers for the processing of minerals and construction materials. Among the commonly used quarry crushers are jaw crusher, cone crusher, and mobile crusher.

Mobile crusher, jaw crusher, cone crusher and impact crusher are essential equipment in various industries, offering unique features and advantages. Jaw crusher is suitable for primary crushing, cone crushers excel in secondary and tertiary crushing, impact crusher provides versatile crushing capabilities, and mobile crusher offers mobility and on-site crushing convenience. Each type of crusher has its own specific applications, depending on the desired final product size, material hardness, and operational requirements. Understanding the characteristics of these crushers helps in selecting the appropriate machine for specific crushing needs.

Mobile crusher is increasingly popular in Zimbabwe's mining industry due to their flexibility and mobility. Mobile crushers, as the name suggests, are crushers that are mounted on a wheeled or tracked chassis, allowing them to be easily transported from one location to another. They are versatile machines that can be used for various applications, such as crushing rocks, ores, and construction waste on-site. Mobile crushers can be equipped with different types of crushers, including jaw crushers, cone crushers, or impact crushers, depending on the specific requirements of the application. They offer the advantage of flexibility, allowing for efficient on-site crushing and reducing the need for material transportation.

Our NK Portable Crusher Plant is a cutting-edge innovation in the realm of mobile crushing technology. The NK Portable Crusher Plant is designed to provide unmatched mobility and flexibility in crushing operations. Its compact design allows for easy transportation between job sites, enabling swift setup and dismantling without compromising on performance. Whether it's for construction, mining, or recycling applications, this crusher stands out for its adaptability and high productivity.

Equipped with advanced features, the NK Portable Crusher Plant boasts a powerful engine capable of handling various types of materials. Its robust construction ensures durability and reliability, even in the most demanding environments. The machine's intelligent control system enhances efficiency while minimizing downtime, contributing to increased operational efficiency and reduced overall costs.

One of the standout characteristics of the NK Portable Crusher is its ability to crush a wide range of materials, from hard rocks to demolition debris. This adaptability makes it an invaluable asset across multiple industries, catering to diverse crushing needs with precision and effectiveness.

Moreover, its user-friendly interface and ease of maintenance make it a preferred choice for operators seeking hassle-free equipment. The crusher's accessibility for servicing and maintenance ensures minimal disruption to operations, maximizing uptime and productivity.

In conclusion, the NK Portable Crusher blend of mobility, adaptability, efficiency, and safety features positions it as a frontrunner in meeting the diverse and challenging demands of various industries. As technology advances and industries evolve, innovations like the NK Portable Crusher continue to shape and revolutionize the way we approach crushing operations.

Jaw crusher is widely used in various industries, including mining, quarrying, and construction in Zimbabwe. They are designed to crush large rocks or ores into smaller pieces. The primary features of a jaw crusher include a fixed jaw and a movable jaw, which form a V-shaped chamber. The material is fed into the chamber and crushed by the movement of the jaws, creating smaller-sized particles. Jaw crushers are known for their high capacity, efficiency, and reliability, making them suitable for primary crushing applications.

Cone crusher is commonly used in Zimbabwe's mining industry for secondary and tertiary crushing stages. They are designed to crush and process hard and abrasive materials such as granite, basalt, and ores. A cone crusher consists of a cone-shaped mantle located inside a concave-shaped bowl. As the mantle gyrates, it compresses the material against the concave, breaking it into smaller pieces. Cone crushers offer advantages such as excellent particle shape, high production capacity, and precise control over the final product size.

An impact crusher consists of a rotor that rotates at high speeds, which impacts the incoming material. The material is then projected against fixed or adjustable impact plates, causing it to break into smaller fragments. Impact crushers are known for their high reduction ratios, excellent cubicity of the final product, and the ability to handle a wide range of materials.

Stone crushers play a vital role in Zimbabwe's mining industry, facilitating ore extraction, supporting infrastructure development, and ensuring efficient quarry operations. They contribute to the growth of the local economy and provide employment opportunities. Moreover, with the adoption of sustainable practices and technological advancements, stone crushers are evolving to meet the industry's changing needs while minimizing their environmental footprint.

Stone crushers are instrumental in the initial stages of ore extraction in Zimbabwe's mining industry. They are used to break down large rocks and ores into smaller fragments, making it easier to transport and process them further.

Stone crushers are utilized in the mineral processing plants of Zimbabwe to crush and grind raw materials for further processing. They enable the extraction of valuable minerals from the ore, contributing to the overall efficiency of mineral processing operations.

Stone crushers provide essential materials for infrastructure development projects in Zimbabwe. They produce crushed stones of different sizes, which are used for constructing roads, bridges, buildings, and other infrastructure projects, thus driving economic growth and development.

Stone crushers are crucial for efficient quarry operations in Zimbabwe. They help in the extraction of stones and minerals from quarries, ensuring a continuous supply of materials for various construction projects and industries.

The stone crushing industry in Zimbabwe creates employment opportunities for a significant number of people. From quarry workers to machine operators and maintenance staff, stone crushers contribute to job creation and the local economy.

Stone crushers in Zimbabwe are increasingly adopting sustainable practices to mitigate their environmental impact. This includes using advanced dust suppression systems and implementing measures to minimize noise pollution and other environmental hazards associated with stone crushing operations.

Advancements in stone crusher technology and innovation have improved efficiency and productivity in Zimbabwe's mining industry. From mobile crushers to advanced automation systems, new technologies are being deployed to optimize the performance of stone crushing operations.

Learn proven ways to reduce crushing plant operating costs, including equipment selection, energy efficiency, wear part control, and process optimization to lower cost per ton and improve ROI.

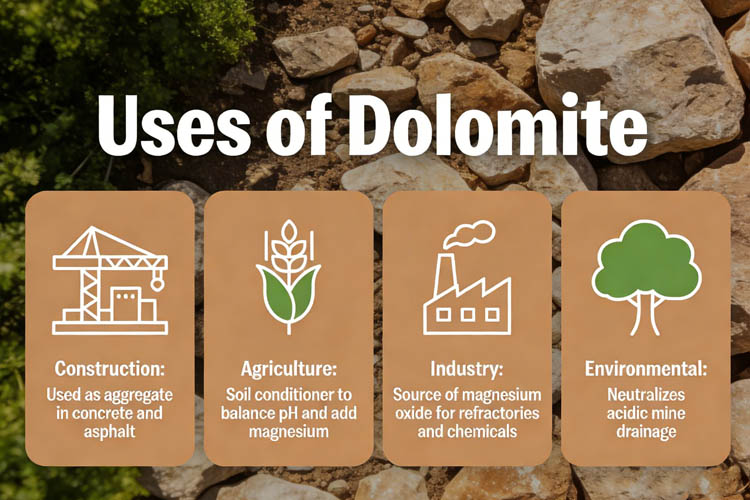

This article will explore 10 prominent uses of dolomite, shedding light on its versatility and highlighting its importance in today’s global economy.

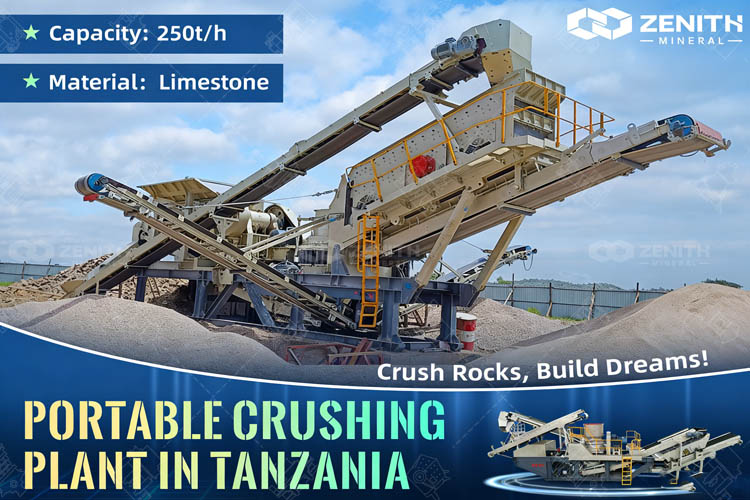

Discover the cost of portable crushing plants in Tanzania. Learn factors affecting price, capacity, mobility options, and how to choose the right solution for your mining or quarry project.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.