Ethiopia, a nation endowed with abundant mineral resources and a rapidly expanding economy, has emerged as a pivotal player in Africa’s mining landscape. With the government designating mining as one of the five core pillars of national development under its 10-year plan, the sector has witnessed unprecedented growth—recording a 115% growth rate in 2021 and contributing over $3.5 billion in revenue in the last fiscal year. This surge is fueled by massive untapped reserves of over 30 metallic, industrial, and construction minerals, coupled with policy reforms aimed at curbing illegal mining and attracting foreign investment.

From the gold-rich greenstone belts of the north to the world-class tantalum mines in the south, and the vast potash deposits in the Danakil Depression, Ethiopia’s mineral wealth spans diverse geological formations. These resources not only support critical sectors like construction, manufacturing, and agriculture but also address the country’s annual $8 billion import bill for commodities such as coal, iron, and marble. Central to unlocking this potential are crushing equipment—essential tools that transform raw ores and rocks into processable materials or construction aggregates.

This article delves into Ethiopia’s dynamic mining market, highlights the key materials being crushed, and profiles the top-selling crushers that have proven indispensable for operators across cities like Addis Ababa, Mekelle, Bahir Dar, and Dire Dawa.

Ethiopia’s diverse mineral resources require specialized crushing solutions tailored to material hardness, composition, and end-use. The most commonly crushed materials include:

The Ethiopian market favors crushers that combine durability, efficiency, and adaptability to challenging operating environments—from the remote mining sites of Western Ethiopia to the bustling construction hubs of Addis Ababa. Below are the four best-selling crusher types, trusted by operators for their performance in processing local materials.

| Crusher Type | Core Advantages | Key Applications in Ethiopia | Target Operators & Market Appeal |

|---|---|---|---|

| Jaw Crushers | Robust, wear-resistant; easy maintenance; versatile fixed/mobile installation | Primary crushing of gold ore, granite, limestone; coal processing | Small-scale miners ($5k–$20k models); large enterprises ($50k–$300k units); |

| Mobile Crushers | Terrain-adaptive chassis; integrated functions; fast deployment; eco-friendly design | Remote mine ore processing; road construction aggregates; waste recycling | Medium-scale operators ($10k–$100k units); multi-site contractors; cuts transportation costs |

| Cone Crushers | Precise size control; high efficiency; durable for abrasives; automated protection | Secondary/tertiary crushing of potash, gold concentrate; high-grade aggregates | Medium to large-scale mining & construction firms ($70,000–$400,000) |

| Impact Crushers | Uniform cubical output; flexible adjustment; low maintenance; compact design | Limestone/marble crushing; rural housing aggregates; phosphate ore processing | Small-scale quarries ($5k–$100k units); local builders; budget-limited projects |

Jaw crushers stand as the most widely used primary crushers in Ethiopia, prized for their ability to handle hard, abrasive materials like granite, iron ore, and gold-bearing rock. Their rugged design and high reduction ratio make them indispensable for initial crushing stages in mines and quarries across the country.

Key Features for Ethiopian Applications:

Popular Applications in Ethiopia:

Market Appeal:

Jaw crushers dominate the Ethiopian market due to their affordability and reliability. Small-scale operators often opt for compact models (10-50 tph, priced at $5,000-$20,000), while medium to large enterprises invest in heavy-duty units ($50,000-$300,000) for high-capacity operations. Brands offering local spare parts supply, such as those with distributors in Addis Ababa, are particularly favored to minimize downtime.

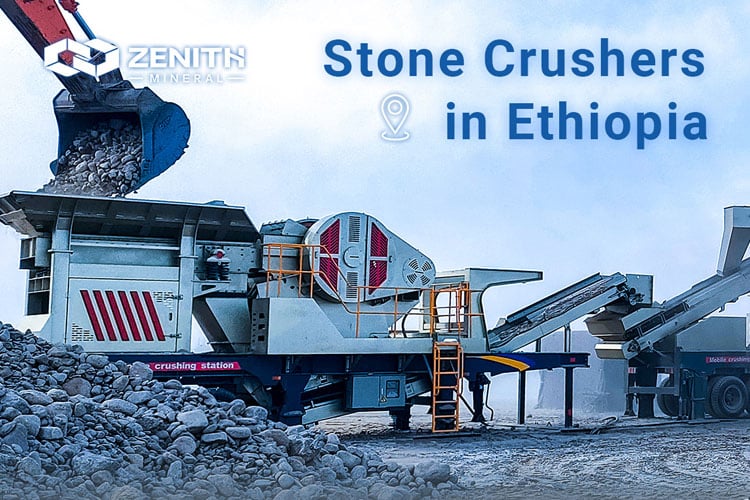

Ethiopia’s mineral deposits are often scattered across remote, hard-to-reach regions—from the tantalum mines of southern Oromia to the gold fields of Western Ethiopia. This geographical challenge has made mobile crushers one of the fastest-growing segments in the country’s crushing equipment market, offering unmatched mobility and on-site processing capabilities.

Key Features for Ethiopian Applications:

Popular Applications in Ethiopia:

Market Appeal:

Mobile crushers address Ethiopia’s core challenge of scattered resources, cutting transportation costs and improving operational flexibility. They are particularly popular among medium-scale operators (50-200 tph capacity, priced at $10,000-$100,000) and large construction companies working on infrastructure projects across multiple locations. The ability to deploy quickly—often within 24-48 hours of arrival—makes them a favorite for time-sensitive projects like road expansions near Dire Dawa.

For applications requiring uniform, high-quality fine aggregates or mineral concentrates, cone crushers are the preferred choice in Ethiopia. Used after jaw crushers for secondary or tertiary crushing, they excel at processing medium to hard materials and producing consistent particle sizes—critical for concrete production and mineral beneficiation.

Key Features for Ethiopian Applications:

Popular Applications in Ethiopia:

Market Appeal:

Cone crushers are valued for their precision and reliability in producing high-quality end products. They are commonly used in medium to large-scale operations, with prices ranging from $70,000-$400,000 depending on capacity and features. Mines focused on export-oriented minerals (like tantalum and gold) and large construction firms prioritize cone crushers for their ability to meet international quality standards, enhancing product competitiveness in global markets.

Impact crushers have gained traction in Ethiopia for processing medium-hard materials like limestone, marble, and construction waste. Their ability to produce cubic-shaped aggregates and high throughput makes them ideal for construction applications, while their versatility supports multiple industries across the country.

Key Features for Ethiopian Applications:

Popular Applications in Ethiopia:

Market Appeal:

Impact crushers are favored for their versatility and cost-effectiveness, with small to medium-capacity models (10-200 tph, priced at $5,000-$100,000) dominating the market. They are particularly popular among small-scale quarry owners and local construction companies due to their ease of operation and ability to handle multiple materials. For projects like rural road construction in the SNNPR Region, impact crushers offer a balance of performance and affordability that aligns with limited budgets.

Selecting the optimal crusher for Ethiopian operations requires careful consideration of several factors, including:

Ethiopia’s mining sector is poised for unprecedented growth, with its abundant mineral resources and government support creating a thriving market for crushing equipment. Jaw crushers, mobile crushers, cone crushers, and impact crushers have emerged as the top-selling models, each addressing specific local needs—from the mobility required for scattered deposits to the precision needed for high-quality aggregates.

As Ethiopia continues to invest in infrastructure, industrialization, and import substitution, the demand for reliable, efficient crushing equipment will only increase. Operators who choose crushers adapted to local conditions—durability for harsh terrains, flexibility for scattered resources, and compliance with environmental regulations—will be well-positioned to capitalize on the country’s mining boom.

As a leading global manufacturer of crushing and grinding equipment with over 30 years of experience, Shanghai ZENITH has established a strong presence in Ethiopia’s dynamic mining sector, earning the trust of local and international operators alike. With a sales network covering more than 180 countries and a dedicated branch office in Ethiopia, ZENITH is uniquely positioned to deliver tailored solutions that address the specific challenges of local mineral processing—from the hard granite in Tigray to the basalt in Dire Dawa and the gold ore in Western Ethiopia.

Our product portfolio in Ethiopia includes the full range of top-selling crushers highlighted in this article, all engineered to withstand the country’s harsh operating conditions. Our C6X jaw crushers, renowned for their high efficiency and wear resistance, are widely used in primary crushing operations across quarries near Addis Ababa and Mekelle. Our mobile crusher series, featuring robust crawler chassis, has been successfully deployed in remote mining sites such as the Kenticha tantalum mine and road construction projects in the Rift Valley, enabling on-site processing and significant transportation cost savings. Additionally, our HPT cone crushers and impact crushers are trusted for producing high-quality aggregates that meet international standards, supporting Ethiopia’s export-oriented mineral projects and large-scale infrastructure developments.

What sets ZENITH apart is our unwavering commitment to local service excellence. Our comprehensive service chain covers every stage of your project: pre-sales, we provide professional on-site surveys and customized solution design based on your material characteristics and capacity needs; during sales, our technical team oversees installation, commissioning, and operator training to ensure smooth startup; after sales, we offer 24/7 online consulting and regular on-site revisits to optimize equipment performance and minimize downtime. This end-to-end support has enabled us to complete many crushing and grinding projects in East Africa, including multiple successful cases in Ethiopia such as the 100-120 TPH granite crushing project in Addis Ababa and the 200 TPH basalt mobile crushing line.

Whether you are a small-scale artisanal miner in Bahir Dar, a medium-sized quarry owner in Oromia, or a large international mining company operating in the Danakil Depression, ZENITH has the right equipment and expertise to power your success.

Choose a reliable stone crusher supplier with this professional guide. Learn key steps: assess needs, check reputation, product quality, after-sales support, and cost-efficiency for optimal operations

This article explores the advantages of using impact crushers for basalt crushing in Ethiopia, highlighting efficiency, cost-effectiveness, and adaptability over cone crushers.

Iron is the fourth most-abundant element, composing approximately 5 per cent by mass of the earth's crust. In the modern industry, iron is the most importan

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.