Iron is the fourth most-abundant element, composing approximately 5 per cent by mass of the earth's crust. In the modern industry, iron is the most important of the metals and the most widely used; the tonnage of pig iron produced in the world is about fifty times as great as that of any other metal, and is probably ten to twenty times as great as the combined tonnage of all non-ferrous metals. Currently, iron mining companies in Ethiopia are becoming increasingly aggressive, and they are seeking high-efficiency iron ore processing plant in Ethiopia. Here we focus on more details of iron ore mining equipment in Ethiopia, taking the iron ore crushing equipment and extraction equipment for example.

Minerals constitute the back-bone of economic growth of any nation and Ethiopia has been eminently endowed with this gift of nature. Thereafter, with progressive industrialization the demand for and hence the production of iron gradually goes up. As the iron mining investors begin to look forward for ways and means to improve efficiency and cut costs, safety considerations certainly assume more and more important position and emerge as significant factor even purely on economic considerations.Currently, more and more investors choose iron ore processing plant from China, where lots of mining equipment has a ratio of price and performance. Typically, main types of iron ore mining equipment in Ethiopia includes the iron ore crusher machine, iron ore grinding mill and iron extraction equipment.

As mentioned above, iron ore crushing equipment is a typical type of iron ore mining equipment in Ethiopia. Typically, iron ore crushing equipment refers to crushing machines used in the crushing process of iron-bearing rocks. It has been proved by practice that PFW series impact crusher performs as an efficient crushing plant when processing iron ore. The PFW series impact crusher is also called European style impact crusher, often used in the secondary crushing and fine crushing. It is very suitable for open-pit iron mining. PFW series impact crushers are adopted by heavy-duty rotor design, unique hammer locking system, and interchangeable wearing parts. This series impact crushers provide customers low cost solutions, outstanding performance, good cubical shape, lowest operation cost per ton, and wide applications.

Iron ore grinding machines have varied types, such as ball mill, rod mill, and vertical mill. Here we focus on one popular type of iron ore grinding machine used in iron mining industry, which is the iron ore ball mill. Most ball mills used in Ethiopia at present are cylindrical. A section of conic cylinder is added at the material discharge end of the original cylinder, which not only increases effective area, but also enables media in the cylinder to be reasonably distributed. Steel balls with relatively large diameters are within the cylinder where raw ores are fed. As the ore blocks are finely grinded in the cylinder, the balls are automatically classified. The closer the balls are to the ore discharge mouth, the smaller the ball diameters are. Therefore, the functions of various balls can be brought into full play to get production of finer grains and increase treatment capacity by 12% to 25%.

Iron ore extraction equipment refers to iron ore mining equipment used in the beneficiation process of iron. ZENITH's dry magnetic separator is widely used in the iron mining industry in Ethiopia. It can meet the requirements of small, medium and large iron ore processing plant in Ethiopia. The Magnetic Separators are available in cyclic design with process vessel diameters smaller than 3mm. Its magnetic system is a ring-shape chain closed magnetic circuit with energizing coils made of copper tube and cooled internally by water. In addition, dry magnetic separator is ideally suitable for arid areas, for it can save water resources, and reduce separation costs, opening up a new way for open-pit iron ore extraction.

When processing iron ores, it is necessary for investors to use special machines for drying iron concentrate. Today, rotary dryer is widely used in many sectors to dry particulate solids. They are made of a long cylindrical shell which can rotate constantly. The shell is usually slightly inclined to the horizontal to induce solids flow from one end of the dryer to the other. Inside the rotary dryer, a hot gas flowing through the dryer provides the heat required for vaporization of the water. So many mining applications have proved that drying machines made by ZENITH feature low noise,low energy consumption, little pollution, and high capacity. Our machines used for drying iron concentrate have found a great market around the world.

We have established a long-term relationship with many iron investors from Ethiopia, a country full of potential. If you need more information on our iron ore processing plant in Ethiopia, please contact us.

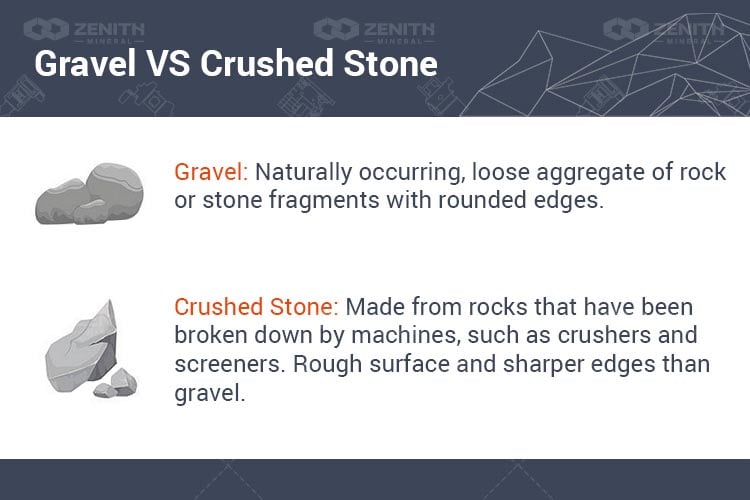

Crushed stone and gravel are two popular materials used for landscaping and construction projects. They both have unique properties and uses, and understanding

The copper ore processing and production process mainly includes three stages: crushing, grinding, and beneficiation.

The common seen gold ore are placer gold ore and rock gold ore. But how to get gold from gold ore? We will introduce 4 gold extraction methods in this article.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.