In recent years, under the concept of green and environmental protection development, the exploitation of natural sand is limited. Manufactured sand has gradually replaced natural sand to become the main force and a hot industry of sand market under the promotion of "One Belt and One Road" strategy, urbanization and infrastructure projects such as highways, subways and railways. The processing technology of manufactured sand and other aggregate on the market is also developing more and more mature.

At present, the common mechanism of sand production process on the market are respectively Wet Process and Dry Process. Dry Process appeared slightly later than the Wet Process, and it is developed on the basis of the traditional Wet Process, so some people think that the Wet Process may not be as advanced as the Dry Process.

So the question is, which process is more suitable for the preparation of manufactured sand?

For this problem, we should analyse from the purpose of the process, production environment and other aspects.

Whether Wet or Dry Process, its essence is to solve the problem of powder and mud in manufactured sand. Due to the fierce collision of stone in the process of crushing and the soil in the stone, so the finished product contains a certain mud and stone powder. At this point, the Dry Process and the Wet Process are the same.

The following is a comparison of Wet Sand Making and Dry Sand Making Processing.

It can be seen that the main equipment used in the two sand making processes is basically the same. It mainly uses crusher and sand making machine, and both can improve the quality of manufactured sand.

The main difference lies in the treatment for the stone powder and mud content in manufactured sand.

After the process of crushing, sand washing mode (equipped with Sand Washing Machine) is used for Wet Process of sand making to reduce the soil content of manufactured sand. The appearance of sand grains is round and the quality is high.

Dry Process is the use of powder selection mode (equipped with Powder Selection Machine) to achieve sand separation, so as to select high-quality sand in line with the construction sand. At the same time, the collected dust can also be used as a by-product.

You can't really tell which one is better than the other.

For this question, the answer is clearly no. There is a market for Wet Process which should not be underestimated.

Reason 1

The traditional Wet Process has many problems, such as large amount of sewage and coarse fineness modulus of finished products, but its advantage lies in the high quality of manufactured sand produced by this process.

In addition, the Wet Process has virtually no requirement for moisture content of raw materials, which may be difficult to achieve in the Dry Process.

Reason 2

The management of aggregate industry changes from extensive to precise, and

people pay more attention to recycling resources and controlling silt content. The traditional Wet Process has the problems of water pollution, low production, high moisture content. Now there are corresponding solutions for these problems.

the front of the production line adopts jaw crusher + desilting screening + pre-screening + cone crusher + vertical shaft impact crusher for shaping+ finished product screening, the back of the production line adopts tower-like sand making process.

Developing high-quality machine-made sand with stable output capacity and quality to replace river sand can not only solve the imbalance between supply and dema

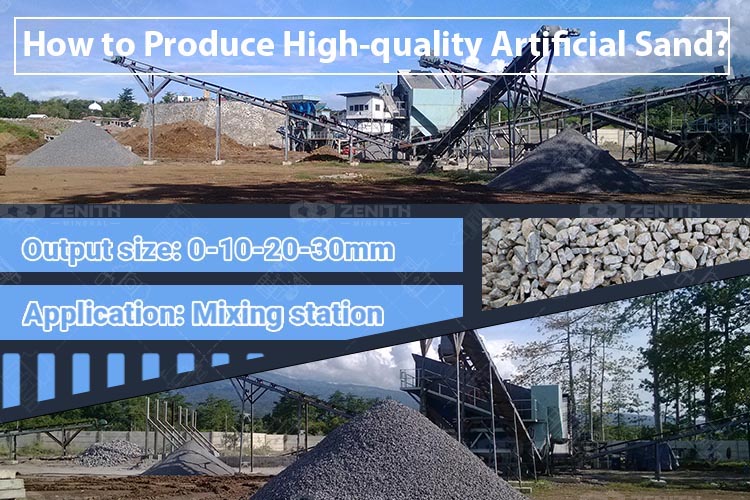

Aggregate is the basic material of engineering construction, which is widely used in electricity, construction, roads, highways and other construction fields.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.