Indonesia is the world’s largest producer of nickel ore, supplying over 30% of global demand (USGS, 2023). The country’s nickel deposits are primarily lateritic (limonite and saprolite) and sulfide ores, each requiring different crushing approaches. Selecting the right crusher is critical for maximizing productivity, reducing downtime, and meeting smelter feed specifications.

This guide will help you choose the best crusher for Indonesian nickel mining, covering:

Nickel ore primarily consists of two types: laterite and sulfide.

Key Challenge: Laterite ores are sticky and abrasive, causing blockages in crushers, while sulfide ores require high-pressure crushing.

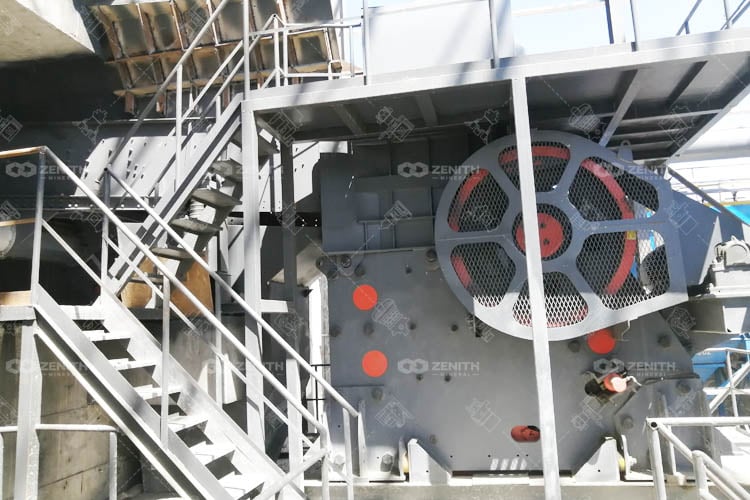

✔ Jaw Crusher

✔ Gyratory Crusher

✔ Cone Crusher

✔ Impact Crusher (For Laterite)

✔ High-Pressure Grinding Rolls (HPGR) (Advanced Option)

Problem: Laterite sticks to crusher walls → downtime for cleaning.

Solution:

Vibrating grizzly feeder (pre-removes sticky fines)

Wet scrubbing system (for high-moisture ore)

Diesel vs. Electric:

Remote mines (e.g., Papua) → Diesel-powered crushers

Grid-connected plants → Electric with soft starters

Top Wear Parts for Nickel Ore:

Manganese jaws (for jaw crushers)

Ceramic-lined chutes (abrasion resistance)

Choosing the right crusher for Indonesian nickel ore involves a comprehensive understanding of the ore's characteristics and the local environmental conditions. By considering factors such as ore type, crushing capacity, energy efficiency, and maintenance requirements, mining operators can select equipment that optimizes production while adhering to environmental regulations. As Indonesia continues to play a pivotal role in the global nickel market, investing in the right crushing technology will be essential for sustainable and efficient mining operations.

The price of stone crusher machines can vary significantly between countries due to factors like local manufacturing, taxes, transportation costs and currency fluctuations.

This comprehensive guide aims to provide detailed insights into different types of stone crusher machines available in Indonesia, their selection criteria, performance evaluation, maintenance considerations, cost analysis, and their suitability for specific applications.

Stone crushers are machines designed to reduce large rocks into smaller rocks, gravel, or rock dust. They are commonly used in the mining, construction, and recycling industries.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.