With the continuous development of technology, the performance of the hydraulic cone crusher has improved significantly, cone crusher is from a single hydraulic crusher upgraded to a variety of forms of hydraulic cone crusher, has a lot of improvement in the performance, and make customers has more assured when using.

The production of hydraulic cone crusher is the latest model of the crushing equipment of ZENITH. The crusher is developed by ZENITH based and drew on the advanced technology. On the structure design, it is different from the traditional cone crusher,it absorbs the advantages of all kinds of cone crusher not only improves the production capacity and crushing efficiency, also enlarged the scope of application, from limestone to basalt, from stone production to all kinds of ores broken; It can realize all kinds of crusher, finely, super fine grinding, crushing performance is strong.

The hydraulic cone crusher according to different performance is divided into single cylinder hydraulic cone crusher and multi cylinder hydraulic cone crusher, the multi-cylinder hydraulic cone crusher was combined with the working principle of single cylinder hydraulic crusher and spring cone crusher then developed. Adopted advanced design concept, so, it has better crushing frequency and eccentric shaft, what can let the broken product fine particle content get higher, make the content of less than silent side discharging mouth reach appropriate amount, significantly increase the processing capacity of the follow-up process,reduce the consumption of comprehensive energy.

The crushing production automation based on automatic control of the crusher. From material preparation to crushing, calculation process, only products sent in one operator in the control room, for each device workings and the various parameters such as liner wear, discharging mouth size, capacity and product size by measuring instrument and sensor with digital, chart display. The operator checks and adjusts the working condition of equipment through the monitor in the control room. Achieved unmanned operate in the crushing field.

The hydraulic cone crusher produced by our company mainly includes HST Single-cylinder Hydraulic Cone Crusher and HPT Multi-cylinder Hydraulic Cone Crusher.

HST Single-cylinder Hydraulic Cone Crusher is a new type of high-efficiency crusher independently developed and designed by ZENITH with many years of experience which absorbed the advanced crusher technology of the United States and Germany. The Cone Crusher combines mechanical, hydraulic, electrical, automatic and intelligent control technologies, and it represents the advanced crushing technology of the world.

Capacity: 45-2130t/h

Max. Input Size: 560mm

Min. Output Size: 4mm

Features: Larger processing capacity, safer and more intelligent, higher efficiency

Maximum feeding size (mm):240

Minimum discharging size (mm): 22

Capacities (t/h): 85-170

Nominal installed power (kw): 90

Maximum feeding size (mm): 560

Minimum discharging size (mm):41

Capacities (t/h):335-1050

Nominal installed power (kw):315

Maximum feeding size (mm):370

Minimum discharging size (mm):25

Capacities (t/h): 460-2130

Nominal installed power (kw): 710

Maximum installed power (kw): 750

Based on the structure of traditional multi-cylinder hydraulic cone crusher with the fixed main shaft and the eccentric bushrotating around the main shaft, and the laminating crushing principle,ZENITH greatly optimizes the structure of HPT Multi-cylinder Hydraulic Cone Crusher, which greatly improves the performance and crushing capability. Meanwhile, the hydraulic lubrication system of HPT Cone Crusher ensures more intelligent and more stable operation.

Capacity: 45-1200t/h

Max. Input Size: 350mm

Min. Output Size: 6mm

Features: Higher crushing ratio, larger processing capacity, better granularity and shape of finished materials

Feed opening (mm):140

Minimum discharging size (mm):19

Capacities (t/h):75-140

Nominal installed power (kw):90

Feed opening (mm): 230

Minimum discharging size (mm):25

Capacities (t/h):220-440

Nominal installed power (kw):220

Maximum installed power (kw):250

Feed opening (mm):350

Minimum discharging size (mm):38

Capacities (t/h):570-1200

Nominal installed power (kw):630

In order to make the technology of cone crusher reached the international level, ZENITH research and experiment continuously, and study of product manufacturing technology and process technology innovation, make hydraulic cone crusher operation more convenient, and easy to realize automation, maintenance is more convenient, also provide customers with high quality after-sales service.

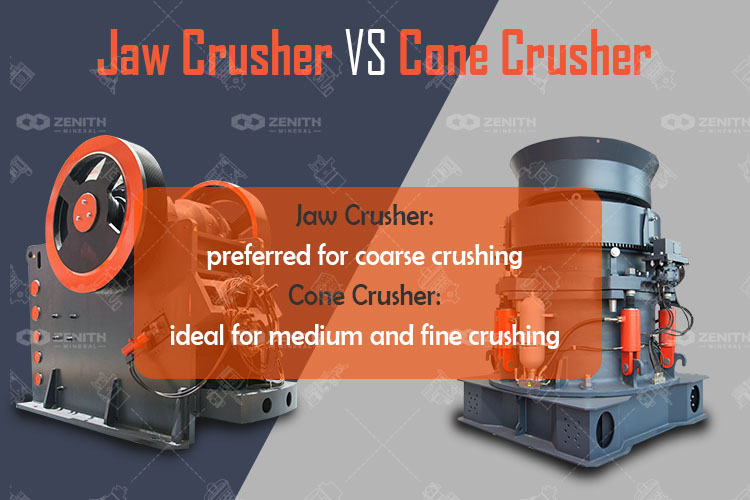

Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

Cone crusher is widely used in mine production due to its high crushing efficiency, low maintenance cost and large output capacity.

Cone crusher is one of the popular medium and fine crushing equipment, which is suitable for crushing all kinds of medium and hard materials.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.