In the realm of aggregates production, the implementation of a comprehensive maintenance plan is crucial to ensure operational efficiency, equipment longevity, and overall productivity. This article delves into the necessity of formulating a maintenance strategy for aggregates production lines, highlighting its significance through various key points.

Regular maintenance schedules help in prolonging the lifespan of machinery and equipment used in aggregates production. By conducting routine inspections, lubrication, and part replacements as needed, the wear and tear on components can be minimized, ultimately extending the operational life of the production line.

A well-structured maintenance plan ensures that all equipment functions optimally, reducing the risk of unexpected breakdowns and downtime. Scheduled maintenance tasks such as cleaning, calibration, and alignment contribute to the smooth operation of the production line, thereby enhancing overall efficiency.

Unplanned equipment failures can lead to costly production interruptions. By proactively identifying and addressing potential issues through a maintenance plan, the likelihood of sudden breakdowns is significantly reduced. This proactive approach helps in maintaining a continuous production flow and meeting production targets consistently.

Regular maintenance not only enhances equipment performance but also contributes to a safer working environment. Well-maintained machinery is less prone to malfunctions that could pose safety hazards to operators and other personnel working on the production line. Prioritizing maintenance fosters a culture of safety within the production facility.

While investing time and resources in maintenance may seem like an additional expense, it proves to be cost-effective in the long run. Preventive maintenance helps in identifying potential issues early on, preventing major breakdowns that could incur substantial repair costs. Moreover, efficient equipment operation leads to higher productivity and reduced operational expenses over time.

In conclusion, the development of a structured maintenance plan for aggregates production lines is essential for ensuring equipment longevity, operational efficiency, production continuity, safety compliance, and cost-effectiveness. By prioritizing regular maintenance activities, production facilities can optimize their processes, minimize disruptions, and achieve sustainable growth in the competitive landscape of the industry.

This comprehensive approach to maintenance planning is fundamental in maximizing the performance and reliability of aggregates production lines, ultimately contributing to the success and profitability of the operation.

The formulation and implementation of a comprehensive spare parts inventory plan for aggregates production lines is a strategic imperative.

Choosing OEM therefore secures equipment reliability and optimized performance for maximum profitability over the equipment's working life.

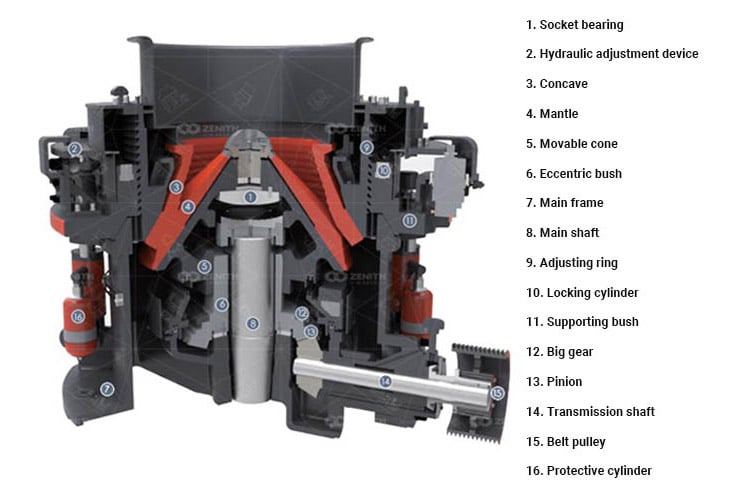

Our HPT series cone crusher uses advanced automation and componentry for high-production applications, understanding key cone crusher parts aids operation and maintenance.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.