Aggregates production lines are characterized by high-intensity operations involving crushers, screens, conveyors, and other machinery. These systems are subject to constant friction, abrasion, and impact, leading to frequent replacement of key components such as jaws, bearings, screens, and belts. The timely availability of these consumable parts is crucial for maintaining production schedules and preventing costly delays.

The primary importance of a well-structured spare parts inventory plan lies in ensuring uninterrupted production. When a critical component fails, having a ready stock of replacements minimizes downtime, allowing for swift repairs and a seamless return to full operational capacity. This, in turn, preserves the production momentum and ensures timely delivery of end products to customers.

An effective inventory plan helps manage costs in several ways. Firstly, it minimizes the need for emergency procurements, often associated with premium pricing due to urgency. Secondly, it prevents overstocking, which ties up working capital unnecessarily. By balancing supply with demand, businesses can optimize inventory levels, reducing storage costs and minimizing waste. Furthermore, regular monitoring and forecasting based on historical data enable more accurate budgeting and cost control.

In a competitive market, rapid response to changes in demand or project requirements is vital. A robust spare parts inventory plan allows for swift adjustments to production capacity by facilitating the rapid replacement of worn-out parts. This agility enables businesses to capitalize on market opportunities and maintain their competitive edge.

Using genuine, high-quality spare parts helps maintain the integrity of production equipment, ensuring consistent product quality and adhering to safety standards. Substandard replacements can compromise equipment performance, leading to increased downtime, poor product quality, and potentially hazardous conditions. A planned approach to spare parts management ensures that only suitable components are used, safeguarding both operational efficiency and personnel safety.

In conclusion, the formulation and implementation of a comprehensive spare parts inventory plan for aggregates production lines is a strategic imperative. It underpins operational continuity, cost efficiency, market responsiveness, and safety compliance. By anticipating component wear, optimizing inventory levels, and ensuring ready access to high-quality replacements, businesses can maximize production output, minimize downtime, and strengthen their competitive position in the market. Thus, investing in a robust spare parts inventory plan is not just a matter of operational necessity; it is a cornerstone of long-term success and profitability.

This comprehensive approach to maintenance planning is fundamental in maximizing the performance and reliability of aggregates production lines, ultimately contributing to the success and profitability of the operation.

Choosing OEM therefore secures equipment reliability and optimized performance for maximum profitability over the equipment's working life.

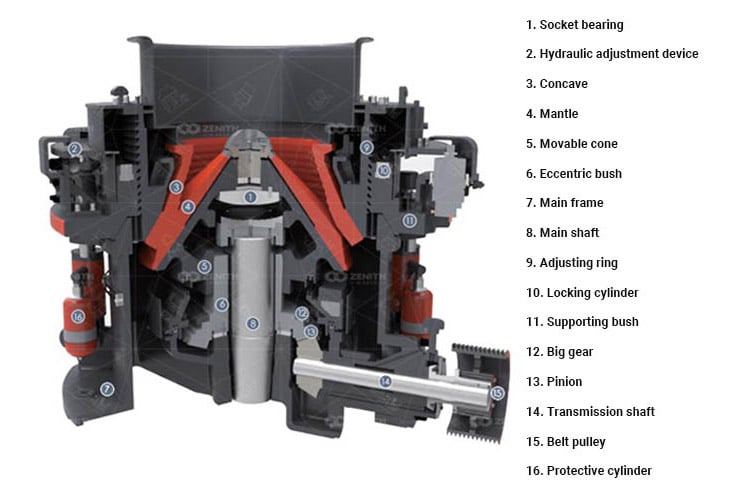

Our HPT series cone crusher uses advanced automation and componentry for high-production applications, understanding key cone crusher parts aids operation and maintenance.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.