Portable crusher plant has revolutionized the processing of raw materials in various industries. Their flexibility to be transported easily and set up near extraction sites provides unmatched advantages over stationary crushers. Understanding source characteristics ensures crushers are matched appropriately to maximize productivity. This article discusses the types of materials suitable for portable crushing and optimal size specifications.

At its core, a portable crusher plant consists of crushing equipment mounted on a mobile asset like a trailer or skid steer frame. Additional components enable complete processing functionality:

Feeder: Vibratory grizzly or apron feeder regulates input material flow into the crushing chamber.

Primary Crusher: Jaw, cone or impact crushers reduce sizes for desired product specifications.

Conveyors: Transport crushed output between processing stages. Belt, pan and screw conveyors are used.

Screens: Multiple decks screen and scalp material into uniform size fractions.

Control Panel: Centralized electrical cabinet automates and monitors crusher operations.

Advanced plants incorporate secondary crushers, dust suppression, stockpile conveyors and remote telemetry. Selecting optimal specifications maximizes the crusher's efficiency.

When investing in a portable crushing plant, it is important to understand the type of raw materials it will be processing on a regular basis.

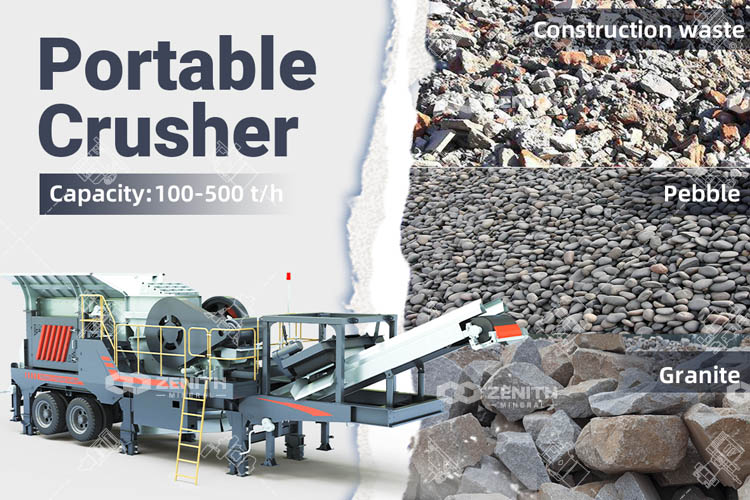

Portable crushers are designed to handle a wide range of raw materials, including aggregates, minerals, ores, and construction waste. They can effectively process materials such as limestone, granite, basalt, sandstone, concrete, and more. By using different configurations and attachments, mobile crushers can be optimized for specific material types, ensuring efficient processing and high-quality output.

Limestone: Building aggregate production from softer calcareous sediments requires impact or cone crushers.

Granite: Quarried for dimension stone and aggregates, granite's hardness necessitates robust jaw crushers with tungsten carbide plates.

Gravel: Alluvial deposits undergo scalping and crushing to manufacture construction aggregates.

Basalt: Highly abrasive black volcanic rock is processed for roadbase and railway ballast using wear-resistant plant components.

Construction Waste: Mobile units recycle construction debris, extracting reinforcing and producing new aggregates.

Iron Ore: Open-pit mining loaders feed primary crushers reducing run-of-mine rocks.

Minerals: Depending on deposit composition, portable crusher liberate valuable metals or industrial minerals.

Optimized sizing maximizes throughput while avoiding choke points. Prudent controls maintain uniform feed characteristics:

Max Feed Size: The max feed size accepted ranges from 500-1000 mm depending on the crusher type (jaw, impact or cone). Jaw crushers typically have a max feed size of 600-1000 mm.

Material Size: Materials are crushed from the max feed size down to approximately 50-100 mm (or smaller depending on need for secondary crushing). Crushed product sizes can be adjusted as required.

Material Shape: Elongated rocks are prone to jamming. Cubical grains promote smooth flow through crushing chambers.

Moisture Content: Most crushers accept materials under 15% moisture to prevent sticking or freezing. Thermal processes may be employed for clay-rich feeds.

Fines Content: High percentages of fines reduce productivity. Additional screening circuits separate desired product from tramp material like soil or dust.

Adhering to optimized sizing practices negates process inefficiencies from improperly sized feed materials. Adjusting portable crusher to source characteristics maximizes capacity utilization.

One of the key advantages of portable crushers is their ability to handle different particle sizes. Whether the requirement is for fine aggregates or large-sized rocks, mobile crushers can be adjusted to produce the desired particle size distribution. This flexibility allows operators to meet specific project requirements and produce materials that meet industry standards.

Portable crusher plant offers a range of crushing configurations to suit specific requirements. From jaw crushers and impact crushers to cone crushers and vertical shaft impactors, these machines can be equipped with different types of crushing chambers and rotors to optimize the crushing process. This versatility allows operators to achieve the desired product shape and size with minimal downtime or adjustments.

In conclusion, portable crusher plant has revolutionized the quarrying and mining industries by offering unparalleled versatility in processing various raw materials, accommodating different particle sizes, and handling materials of varying hardness. Their ability to adapt to diverse material characteristics, coupled with advanced control systems and automation, has significantly improved operational efficiency and productivity. As the industry continues to evolve, portable crusher plant will undoubtedly play a crucial role in meeting the challenges of processing different materials and achieving sustainable quarrying and mining practices.

The mobile crusher industry in the Philippines is experiencing significant growth due to the increasing demand for efficient and flexible crushing solutions, it is important for buyers to consider key factors and stay informed about industry trends.

This comprehensive guide aims to provide detailed insights into different types of stone crusher machines available in Indonesia, their selection criteria, performance evaluation, maintenance considerations, cost analysis, and their suitability for specific applications.

Crushing and screening equipment is the key to the recycling of construction waste. For construction waste treatment, ZENITH recommends mobile crusher.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.