Vertical Shaft Impact (VSI) Crusher also know as a sand making machine, which is a type of impact crusher that utilizes a high-speed rotor with wear-resistant tips to crush and shape the aggregate or rock fed into the machine.

ZENITH Vertical Shaft Impact Crusher models: VSI, VSI5X and VSI6X sand making machine.

These models are commonly utilized in the mining and construction industries to produce high-quality aggregates, sand, and gravel. They are designed to deliver high throughput, ensuring efficient production rates. Furthermore, these crushers are known for generating good grain size and low powder output, resulting in superior quality final products. With their reliable performance and versatility, ZENITH's VSI crushers are trusted solutions for achieving optimal results in various applications within the mining and construction sectors.

The VSI crusher consists of a vertical rotating shaft with a rotor at its center. The rotor is equipped with wear-resistant tips or anvils that accelerate and throw the material against the stationary anvils or curtains lining the crushing chamber.

As the material enters the crushing chamber, it experiences high-speed impact forces generated by the rotating rotor. This impact crushes the material, causing it to break and deform along its natural fractures, resulting in the desired shape and size reduction.

Vertical Shaft Impact Crusher offers excellent particle size control due to their ability to selectively crush the material. The adjustable rotor speed, along with the configuration of the anvils and curtains, allows operators to regulate the size and shape of the final product according to specific requirements.

The high-speed rotor and the crushing chamber design optimize the energy transfer and impact forces, ensuring efficient and effective crushing. This results in higher production rates and improved overall crushing efficiency compared to other types of crushers.

VSI crushers are capable of processing a wide range of materials, including hard and soft rocks, ores, and industrial minerals. They are often used for producing fine and cubical-shaped aggregates for use in concrete production, asphalt mixes, and road construction.

VSI crushers are designed for durability and require minimal maintenance. The use of wear-resistant materials for the rotor and crushing chamber components ensures a longer lifespan, reducing downtime and maintenance costs.

VSI crusher typically produce less noise and dust compared to other crushing equipment, making them more environmentally friendly. Additionally, the use of VSI crushers allows for the production of high-quality manufactured sand from hard rock, reducing the need for natural sand extraction and promoting sustainable practices.

In conclusion, a Vertical Shaft Impact Crusher is a powerful tool for crushing and shaping aggregates, rocks, and minerals. Its ability to produce high-quality, well-shaped products with controlled particle sizes, along with its versatility and low maintenance requirements, make it an essential machine in the mining, construction, and recycling industries.

Developing high-quality machine-made sand with stable output capacity and quality to replace river sand can not only solve the imbalance between supply and dema

In order to keep the sand making machine in good working condition when it starts to operate in spring next year, winter equipment maintenance is particularly important.

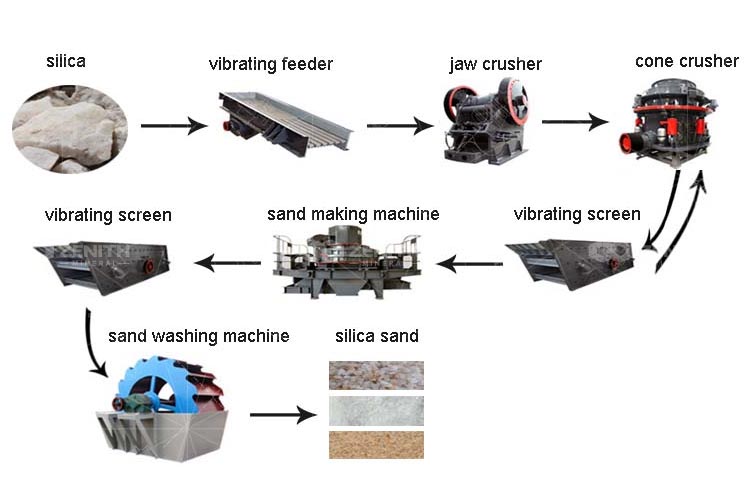

From the perspective of development process, silica sand is widely used in glass, casting, ceramics and refractory materials, metallurgy, construction, chemical industry, plastics, rubber, abrasives and other industries.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.