Stone crushers play a crucial role in various industries such as mining, construction, and road infrastructure. One of the key concerns for users of stone crushers is the control of product granularity and ensuring high-quality output. This article discusses the significance of product granularity and the methods employed for quality control in stone crushing operations.

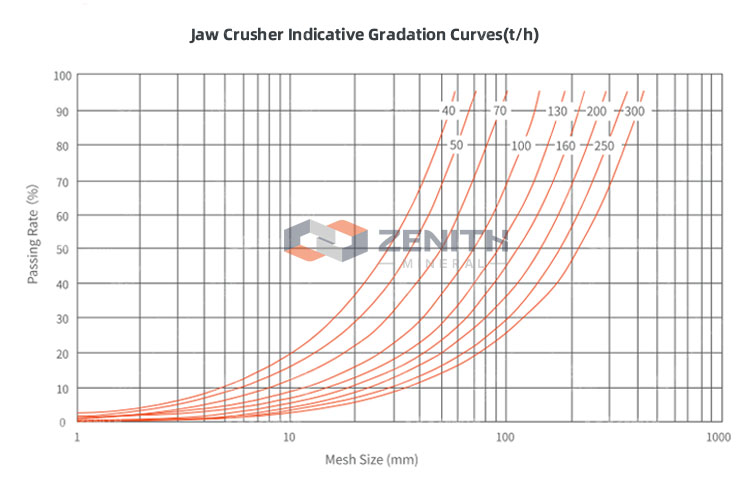

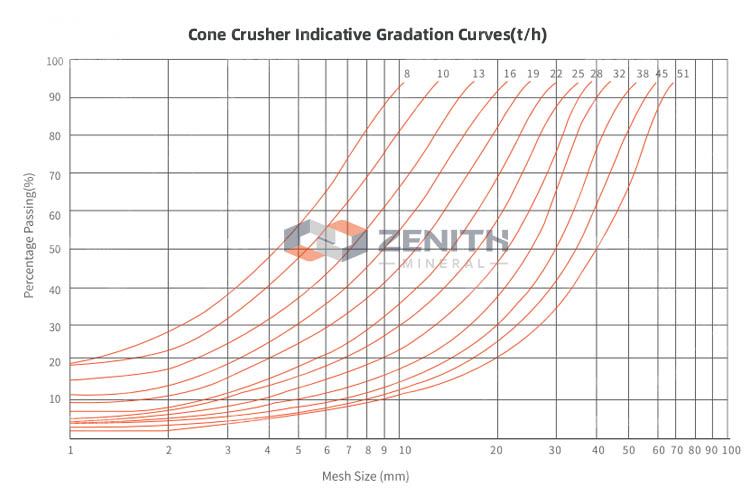

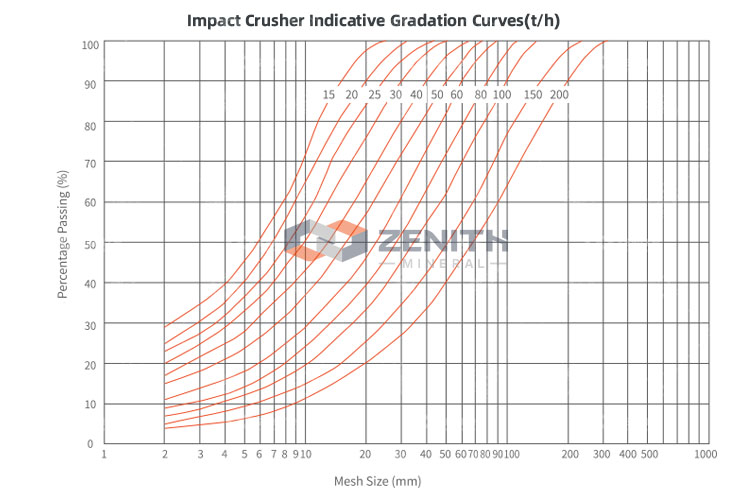

Product granularity refers to the size distribution of crushed stones produced by the crusher. It directly impacts the suitability of the stones for specific applications. Different construction projects or industrial processes require stones with precise gradations. For example, concrete production demands a well-graded aggregate, while road construction may require specific size fractions to ensure stability and durability.

Several factors influence the product granularity achieved by a stone crusher:

Jaw crusher, cone crusher, and impact crusher are the most commonly used types of stone crushers, and their final product shape may vary depending on the type of crusher, chamber design, setup, and feeding characteristics. Here is a general overview of the typical final product shapes for these crushers:

To ensure high-quality output, stone crushing operations employ various quality control measures

Product granularity and quality control are critical factors in stone crushing operations. By achieving the desired product size and maintaining high-quality output, stone crushers enable industries to meet specific project requirements and market demands. Through the implementation of effective control measures, including adjustable discharge openings, screening processes, and regular particle size analysis, stone crusher operators can ensure consistent product quality and enhance their competitiveness in the industry.

By prioritizing product granularity and quality control, stone crusher users can optimize their operations, meet industry standards, and contribute to the success and sustainability of various construction and infrastructure projects.

There are many types of stone crusher machines on the market. In this article, we will introduce the types and price of the stone crusher and how to select the most suitable one.

Stone crushers are machines designed to reduce large rocks into smaller rocks, gravel, or rock dust. They are commonly used in the mining, construction, and recycling industries.

The hydraulic cone crusher according to different performance is divided into single cylinder hydraulic cone crusher and multi cylinder hydraulic cone crusher.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.