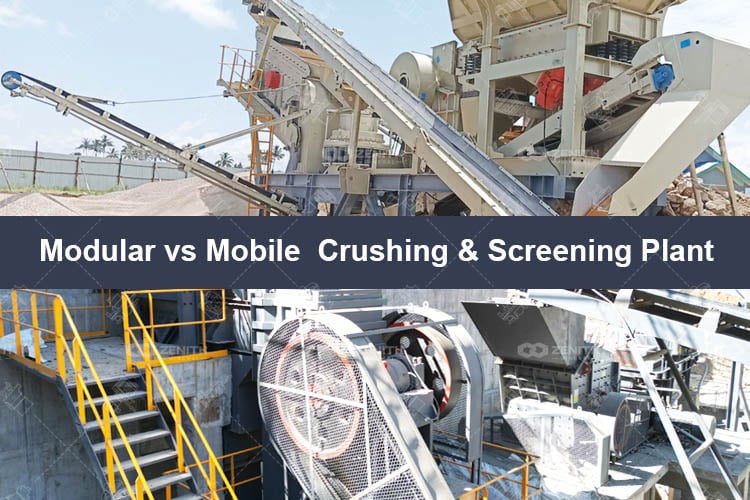

In the mining, construction, and aggregate industries, the choice between a Mobile Crushing & Screening Plant and Modular Crushing & Screening Plant is a critical decision that can significantly impact the efficiency, cost - effectiveness, and success of a project. Both Mobile Crushing & Screening Plant and Modular Crushing & Screening Plant offer unique advantages, and understanding the key factors involved in this decision - making process is essential for making an informed choice. This article will explore the various aspects that should be considered when choosing between these two types of equipment, helping industry professionals and project managers determine the most suitable option for their specific needs.

The Mobile Crushing & Screening Plant is a highly versatile and portable piece of equipment. It typically combines a feeder, a crushing unit (such as a jaw crusher, impact crusher, or cone crusher), a conveyor belt, and in some cases, screening equipment. All these components are integrated onto a mobile chassis, either on tires or tracks, allowing for easy transportation and quick setup at different job sites.

Tire - type Mobile Crushers

Track - mounted Mobile Crushers

1. Construction and Demolition Waste Recycling

Mobile Crushing & Screening Plants are widely used in recycling construction and demolition waste. They can be easily moved to the site of a demolition project, where they can crush concrete, bricks, and other waste materials into reusable aggregates. This not only reduces the need for transporting waste to a landfill but also provides a cost - effective source of building materials for new construction projects.

2. Small - scale Mining and Quarrying

In small - scale mining operations or quarries where the production volume is not extremely high and the need for flexibility in location is important, Mobile Crushing & Screening Plants are a popular choice. They can be used to crush ore or rock on - site, reducing the need for transporting large amounts of raw materials to a central processing plant. For example, in a small limestone quarry, a mobile crushing & screening plant can be moved around the quarry to process the limestone as it is extracted.

3. Road Construction Projects

During road construction, Mobile Crushing & Screening Plant can be used to produce aggregates for road bases and surfaces. They can be positioned near the construction site, reducing the transportation distance of aggregates and ensuring a steady supply of the required materials. This is especially beneficial in remote areas where access to a fixed - location crushing plant may be difficult.

A Modular Crushing & Screening Plant is a more complex and often larger - scale system that consists of multiple pre - engineered modules. These modules can include different types of crushers (jaw, cone, impact), screens, feeders, and conveyors. The modular design allows for a high degree of customization, as the modules can be combined and configured according to the specific production requirements of a project. Modular Crushing & Screening Plants are typically designed for larger - scale and more long - term operations.

1.Crushing Modules

2. Screening Modules

Screening modules in modular crushing & screening plant is used to separate the crushed material into different size fractions. They can be equipped with different types of screens, such as vibrating screens or circular screens, depending on the specific screening requirements. The screened material can then be further processed or sent to the appropriate storage or shipping area.

3. Feeder and Conveyor Modules

Feeders in modular plants are responsible for evenly feeding the material into the crushers at a controlled rate. Conveyor modules are used to transport the material between different components of the plant, from the feeder to the crusher, between different crushing stages, and from the crusher to the screening module and finally to the storage or shipping area.

1. Large - scale Mining Operations

In large - scale mining, Modular Crushing & Screening Plants are the preferred choice. They can handle the high production volumes required in mines, processing large amounts of ore or rock efficiently. For example, in a large copper mine, a Modular Crushing & Screening Plant can be set up to process thousands of tons of copper - bearing ore per day. The modular design allows for easy expansion or modification of the plant as the mining operation evolves.

2. Industrial Aggregate Production

For large - scale industrial aggregate production, Modular Crushing & Screening Plant offer the advantage of high - volume production and precise control over the product quality. They can be configured to produce a wide range of aggregate sizes, meeting the demands of various industries such as construction, concrete production, and asphalt manufacturing. A large - scale aggregate production plant supplying materials to multiple construction projects in a region will often use a Modular Crushing & Screening Plant to ensure a consistent supply of high - quality aggregates.

3. Infrastructure Development Projects

In major infrastructure development projects, such as large - scale road building, bridge construction, or dam building, Modular Crushing & Screening Plants can be set up to produce the required aggregates on - site. This reduces the transportation costs associated with bringing in aggregates from external sources and ensures a reliable supply of materials for the project. For example, in the construction of a large - scale highway network, a modular crushing plant can be installed near the construction site to produce the aggregates needed for the road base and surface layers.

Mobile Crushing & Screening Plant for Small - scale and Flexible Projects

If a project is small - scale, such as a single - site construction project with a limited amount of material to be crushed or a small - scale mining operation with a relatively low production target, a Mobile Crushing & Screening Plant is often a suitable choice. Its flexibility allows for easy adaptation to the project's needs. For example, a small - scale landscaping project that requires the crushing of a few hundred tons of rock for decorative purposes can use a mobile crusher. The Mobile Crushing & Screening Plant can be quickly moved to the site, set up, and operated for the duration of the project, and then easily transported to another location if needed.

Modular Crushing & Screening Plant for Large - scale and Long - term Projects

For large - scale projects with high production requirements and a long - term operation plan, modular crushing and screening plants are more appropriate. In a large - scale quarry operation that is expected to produce hundreds of thousands of tons of aggregates per year over a period of several years, a modular crushing and screening plant can be designed and installed to meet the high - volume production needs. The modular nature of the plant also allows for future expansion as the demand for aggregates grows.

Mobile Crushing & Screening Plant in Challenging Terrains

Mobile Crushing & Screening Plant, especially track - mounted ones, are well - suited for sites with difficult terrains. In mountainous regions, areas with soft ground, or locations with limited access, a Mobile Crushing & Screening Plant can be easily moved to the desired location. For instance, in a remote mining area where the roads are not well - developed, a track - mounted mobile crusher can be used to process the ore on - site without the need for extensive road construction to transport the ore to a fixed - location plant.

Modular Crushing & Screening Plant Requiring Stable Ground and Infrastructure

Modular Crushing & Screening Plant need a stable and level ground for installation. They also require a certain level of infrastructure, such as a reliable power supply and access to water (if needed for dust suppression). In a large - scale industrial area with well - developed infrastructure, setting up a modular crushing plant is more feasible. The plant can be installed on a prepared foundation, and the infrastructure can support its continuous and efficient operation.

Limited Capacity of Mobile Crushing & Screening Plant

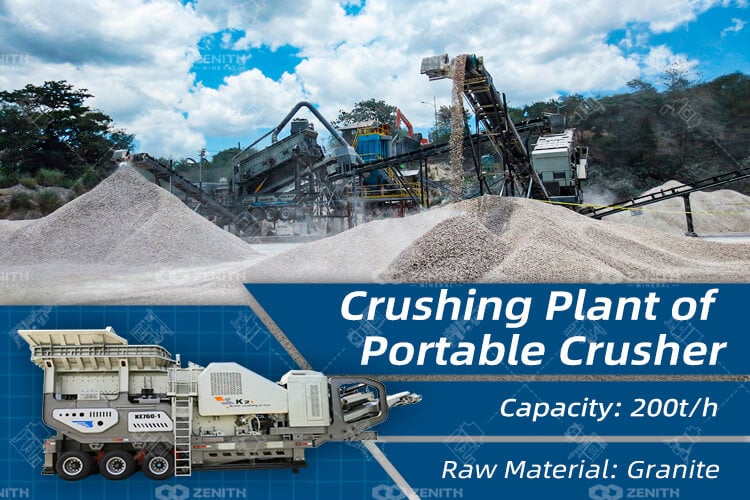

Mobile Crushing & Screening Plant generally have a lower production capacity compared to modular crushing plants. Their size and the fact that they are designed for mobility limit the amount of material they can process per hour. However, for projects with relatively low production requirements, this may not be a drawback. For example, a mobile crusher with a capacity of 50 - 200 tons per hour can be sufficient for a small - scale recycling project where the amount of construction waste to be processed is not large.

High - capacity Modular Crushing & Screening Plants

Modular Crushing & Screening Plants are designed to handle high production volumes. They can be configured with multiple crushers and other components to achieve production capacities ranging from several hundred to thousands of tons per hour. In a large - scale mining operation where the daily production target is in the thousands of tons, a modular crushing and screening plants can be customized to meet this high - volume requirement.

Lower Initial Investment in Mobile Crushing & Screening Plant

Mobile Crushing & Screening Plant usually require a lower initial investment compared to modular crushing and screening plants. Their smaller size, simpler design, and lower manufacturing costs contribute to this. For a small - scale contractor or a start - up mining operation with limited capital, a mobile crusher can be a more affordable option. However, it's important to note that the long - term operational costs may be higher in some cases.

Higher Initial but Lower Long - term Operational Costs in Modular Crushing & Screening Plants

Modular Crushing & Screening Plants have a higher initial investment due to their complex design, larger size, and more advanced components. However, once installed and operational, they often have lower operational costs per unit of output. They are more energy - efficient, require less frequent maintenance in some cases (due to their heavy - duty construction), and can process large volumes of material more cost - effectively in the long run. For a large - scale project with a long lifespan, the higher initial investment in a modular crushing and screening plants can be offset by the lower operational costs over time.

Greater Flexibility of Mobile Crushing & Screening Plant

Mobile Crushing & Screening Plant offer unparalleled flexibility. They can be quickly moved from one site to another, allowing for easy adaptation to changing project requirements. If a construction project has multiple sites where crushing is required, a mobile crusher can be transported to each site as needed. It can also be used in projects with uncertain or changing production volumes, as it can be easily adjusted or removed from the site if the need for crushing decreases.

Limited but Configurable Flexibility in Modular Crushing & Screening Plant

Modular Crushing & Screening Plant has a more limited form of flexibility. While they can be configured to handle different types of materials and production requirements at the time of installation, reconfiguring them during operation can be more difficult and costly. However, their modular design does allow for some degree of customization, such as adding or removing certain modules to change the production process or capacity, but this is a more long - term and complex process compared to the easy mobility of mobile crushers.

Higher Emissions in Mobile Crushers during Movement

Mobile Crushing & Screening Plant, especially when in operation and movement, may emit more noise and air pollution compared to modular crushing plants. The engines used for powering and moving the mobile crusher can produce exhaust emissions, and the crushing process itself can generate dust. In areas with strict environmental regulations regarding air and noise pollution, this may be a factor to consider. However, some modern mobile crushers are equipped with advanced dust - suppression and emission - control systems to mitigate these issues.

Lower Emissions during Operation in Modular Crushing & Screening Plant

Modular crushing plants, once installed, can be designed with more comprehensive environmental control measures. They can be equipped with large - scale dust - collection systems, noise - reducing enclosures, and more efficient power - generation or connection systems. Although the installation process of a modular crushing plant may have a larger environmental impact in terms of land disturbance and resource use, during its long - term operation, it can often achieve lower emissions per unit of output compared to mobile crushers.

Challenges in Maintaining Mobile Crushing & Screening Plant

Mobile Crushing & Screening Plant, due to their frequent movement and exposure to different operating conditions, may require more frequent maintenance. The mobile components, such as the tires or tracks, and the engine (if self - powered) need regular inspection and servicing. Finding specialized service providers for mobile crushers in some remote areas can also be a challenge. However, some manufacturers offer comprehensive maintenance packages and training to help owners manage these maintenance requirements.

Easier Maintenance in Modular Crushing Plants in Some Aspects

Modular crushing plants, being fixed - location installations, can have more stable maintenance schedules. The components are often more accessible for maintenance, and local service providers may be more familiar with the types of equipment used in modular plants. However, the complexity of the plant means that maintenance may require a more skilled workforce, and the cost of replacing major components can be high.

Choosing between a mobile crushing and screening plant and a modular crushing and screening plant is a complex decision that depends on a variety of factors. Project scope, site conditions, production capacity requirements, initial investment and operational costs, flexibility, environmental impact, and maintenance and serviceability all play crucial roles in this decision - making process. For small - scale, flexible projects in challenging terrains with lower production requirements, a mobile crushing and screening plant may be the ideal choice. On the other hand, for large - scale, long - term projects in areas with stable infrastructure and high production demands, a modular crushing and screening plant is likely to be more suitable.

The installation of a stone crushing plant is a crucial stage that requires expert planning and execution to ensure smooth operations.

When comparing portable rock crushers to stationary crushers, there are several factors to consider, including mobility, flexibility, efficiency, and cost.

The mobile crusher is very popular in South Africa, Which has helped our customers create great value, so what's the magic of this equipment?

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.