Tuff, a type of volcanic rock, is widely used in construction due to its lightweight, insulation properties, and aesthetic appeal. As urban development and infrastructure projects continue to grow, the demand for tuff aggregates has increased significantly. To meet this demand, efficient crushing plants capable of processing large volumes of tuff are essential.

Tuff is formed from volcanic ash that has compacted and cemented over time. It is characterized by its porous structure, which contributes to its lightweight nature. Key properties of tuff include:

Tuff is utilized in various construction applications, including:

With the growth of the construction industry, the demand for tuff products has surged. Urbanization, infrastructure development, and the push for sustainable building materials have all contributed to this trend. As a result, efficient processing facilities are required to produce high-quality tuff aggregates.

Crushing tuff offers several advantages:

The following specifications are typical for a 400t/h tuff crushing plant:

A 400t/h tuff crushing plant is designed for high efficiency and productivity. Key components include:

The primary crushing stage is critical for size reduction. Key steps include:

After primary crushing, the material is sent to the secondary crusher for further size reduction:

The crushed tuff is then screened to separate materials based on size:

Once screened, the tuff aggregates are stockpiled or transported for sale. Efficient handling systems ensure minimal losses during this stage.

Selecting the right crushers is vital for the efficient operation of a tuff crushing plant. The choice of crusher significantly impacts the quality of the final product, operational efficiency, and overall production costs. Here, we discuss the common types of stone crushers used in tuff processing and their specific advantages:

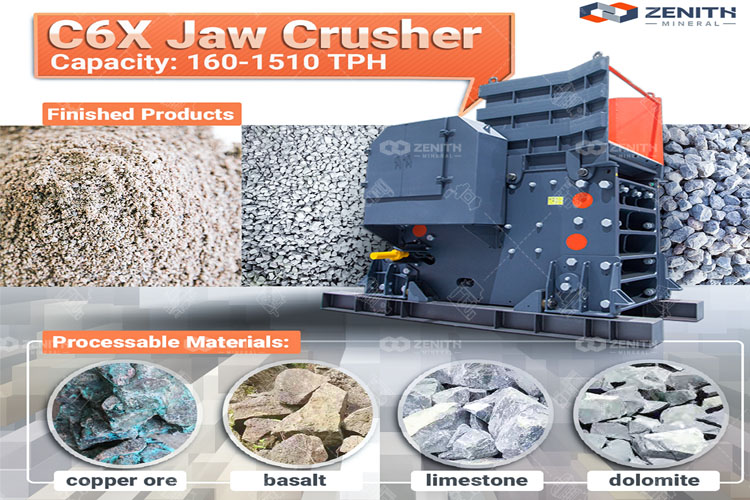

Jaw crusher is one of the most widely used primary crushers in the industry. They operate on the principle of compressive force, where material is crushed between two jaws—one stationary and the other moving.

Key Features:

Applications: Commonly used in the initial crushing stage, jaw crushers effectively reduce run-of-mine tuff into smaller, manageable pieces for further processing.

Cone crusher is typically used for secondary or tertiary crushing. They operate using a rotating mantle that crushes material against a stationary bowl.

Key Features:

Applications: Ideal for further reducing the size of tuff after primary crushing, cone crushers produce a more refined aggregate suitable for various construction applications.

Impact crusher utilize high-speed impact forces to break down materials. They are particularly effective for producing high-quality cubical aggregates.

Key Features:

Applications: Frequently used in the tertiary crushing phase, impact crushers are effective for producing fine aggregates and meeting stringent specifications for different construction applications.

When selecting crushers for a tuff crushing plant, several factors should be considered to ensure optimal performance:

By carefully considering these factors, operators can select the most appropriate crushers for their tuff processing needs, ensuring high productivity, low operational costs, and superior product quality.

A 400t/h tuff crushing plant represents a vital component in meeting the growing demand for high-quality tuff aggregates in the construction industry. By employing advanced technologies, efficient processes, and sustainable practices, these plants can maximize productivity while minimizing environmental impact. As the industry continues to evolve, the importance of effective tuff processing will only increase, ensuring that it remains a key resource for construction and infrastructure development.

Copper ore beneficiation is a critical component of the mining process, ensuring that valuable copper minerals are efficiently extracted and processed.

Understanding the technical specifications of jaw crusher is essential for selecting the right crusher that meets your operational needs. This comprehensive technical guide covers the key details you need to know when evaluating jaw crusher models for your mining application.

This article delves into the intricacies of limestone crushers and the limestone crushing plant, highlighting the importance of this phase in limestone processing.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.